For the circuit board industry laser cutting or drilling, only a few watts or more than ten watts of UV laser can, without kilowatt level laser power, in consumer electronics, automotive industry or robot manufacturing technology, the use of flexible circuit boards is becoming increasingly important. Because UV laser processing system has flexible processing mode, high precision processing effect and flexible and controllable processing process, it has become the first choice of flexible circuit board and thin PCB laser drilling and cutting.

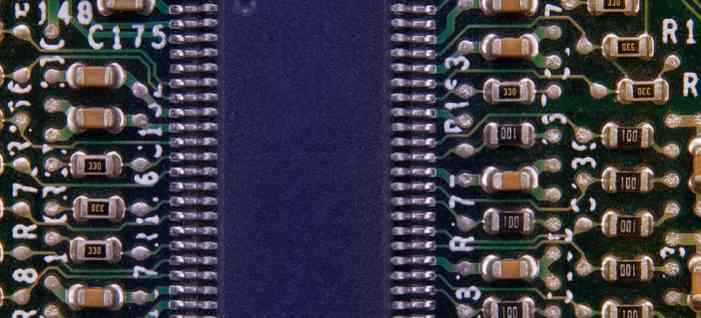

Figure 1: A CO2 laser (left) compared to a UV laser (right) cutting slot. UV laser produces small thermal effect, and its cutting edge is clean and neat

Today, the laser system configuration of long life laser sources has been basically close to maintenance free, in the production process, laser class 1, safety without other protection devices. The LPKF laser system is equipped with a suction device, which does not cause the emission of harmful substances. Coupled with its intuitive and easy to operate software control, laser technology is replacing traditional mechanical processes, saving the cost of special tools.

CO2 laser or UV laser?

For example, when a PCB is divided or cut, a CO2 laser system with a wavelength of about 10.6 μm can be selected. The processing cost is relatively low and the laser power can be up to several kilowatts. But it generates a lot of heat during the cutting process, resulting in severe carbonization of the edges.

UV laser wavelength is 355 nm. Laser beams of this wavelength are very easy to focus optically. A focused UV laser with less than 20 watts of laser power produces a spot only 20μm in diameter -- and an energy density comparable even to the surface of the sun.

Advantages of UV laser processing

UV laser is especially suitable for hard board, soft and hard combined board, soft board and its auxiliary materials cutting and marking. So what are the advantages of this laser process?

UV laser cutting system has shown great technical advantages in PCB sub-boards and micro-drilling in PCB industry. Depending on the thickness of the circuit board material, the laser cuts one or more times along the desired contour. The thinner the material, the faster the cutting. If the accumulated laser pulse is lower than the laser pulse required to penetrate the material, only scratches will appear on the surface of the material; Therefore, two-dimensional code or bar code can be marked on the material to facilitate the follow-up process information tracking.

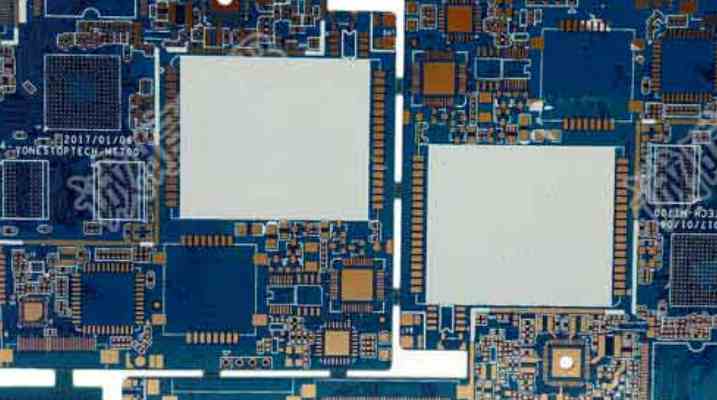

Figure 2: Multiple components on one substrate can be securely separated even if they are close to the line

The pulse energy of the UV laser is only applied to the material for the time of microsecond, and there is no obvious thermal effect at a few micrometers beside the notch, so there is no need to consider the damage caused by the heat generated on the element. The wiring and solder joints near the edge are intact and burr free.

In addition, LPKF UV laser system integrated CAM software can directly import the data derived from CAD, edit the laser cutting path, form the laser cutting contour, select the processing parameter library suitable for different materials, can be directly laser machining. The laser system is not only suitable for mass production, but also suitable for sample production.

Drilling application

The through hole in the circuit board is used to connect the front and back lines of the double panel, or used to connect any interlayer lines in the multilayer board. To conduct electricity, the wall of the hole needs to be coated with metal after drilling. Nowadays, the traditional mechanical method has been unable to meet the requirements of the smaller and smaller diameter of the drilling hole: although the spindle speed is improved, the radial velocity of the precision drilling tool will be reduced because the diameter is too small, even unable to complete the required machining effect. In addition, from an economic perspective, tool consumables that are easy to wear are also a limiting factor.

A new laser drilling system is developed for drilling flexible circuit boards. The LPKFMicroLine 5000 laser unit features a 533mm x 610 mm worksurface for automated roll-to-roll operations. When drilling, the laser can first cut the outline of the microhole from the center of the hole, which is more accurate than normal methods. The system can drill microholes with a minimum diameter of 20μm in organic or non-organic substrates with a ratio of height to depth. Flexible circuit boards, IC substrates, or HDI circuit boards all require such precision.

Semi-cured sheet cutting

In the manufacture of electronic components, what situations require the cutting of semi-cured sheet material? As early as the beginning, semi-cured sheet materials have been used in multilayer circuit boards. Each circuit layer in the multilayer circuit board is pressed together by the action of semi-cured sheet; Depending on the circuit design, some areas of the semi-cured sheet need to be cut and then pressed together.