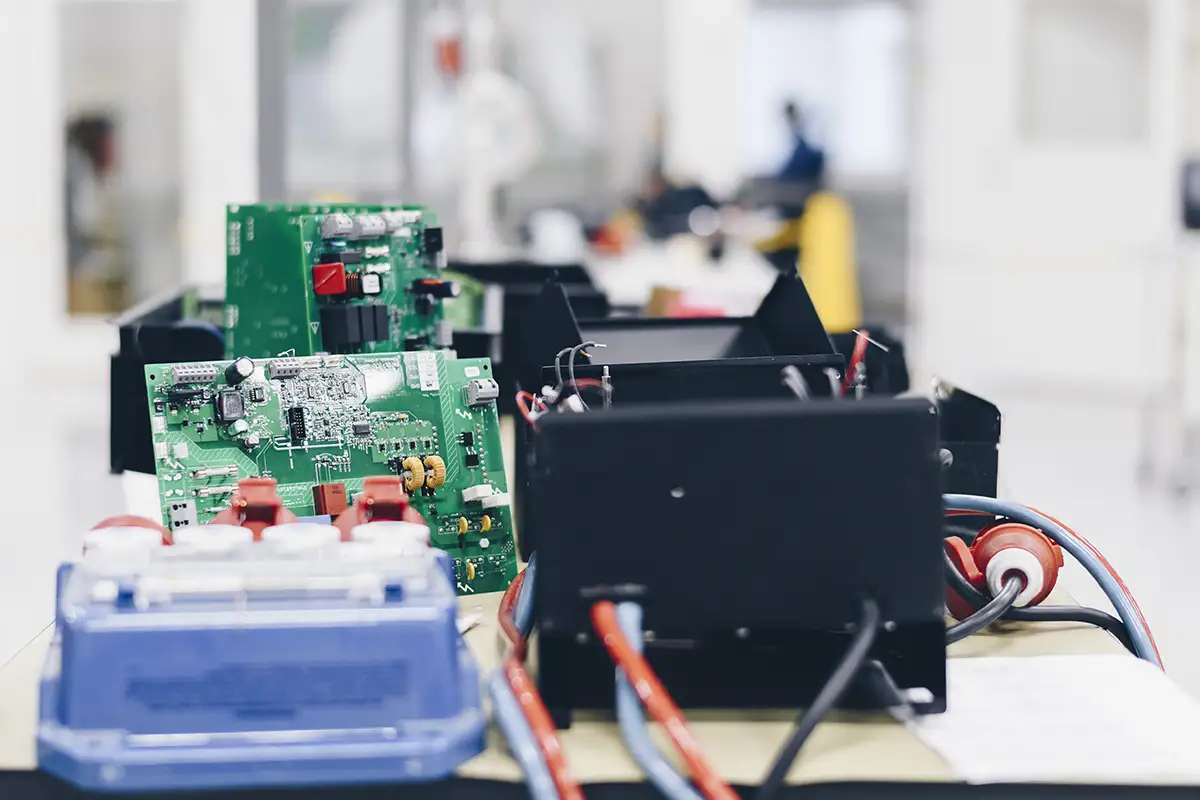

Concept Refers to the process of soldering and assembling electronic components on prefabricated matting and manufacturing printed circuit boards (PCBs). Usually with professional production machinery, mass production, the printed circuit board assembly process is usually called PCBA.

So how is the PCB assembled?

Let's take a look at the PCB assembly process:

1. Application of solder paste: First, apply solder paste (a small particle of solder paste mixed with flux) on the board. For this application, most PCB manufacturers use stencils (available in several sizes, shapes, and gauges to spec) that only apply the correct amount of solder paste to certain parts of the board correctly.

2. Placement of components: Unlike in the past, the PCB assembly process at this stage is now fully automated. Picking and placing of parts, such as surface mount assemblies, was once done manually and is now performed by robotic pick and place machines. These machines place components accurately into pre-planned areas of the board.

3. Reflow: With the solder paste and all surface mount components in place, curing the solder paste to the correct specifications is critical to properly adhering the PCB components to it. Here's this relevant part of the PCB assembly process - reflow soldering. To do this, the component with solder paste and the components on it are passed through a conveyor belt, which passes through an industrial grade reflow oven. A heater in the oven melts the solder in the solder paste. Once melting is complete, the components are again moved on the conveyor belt and exposed to a series of cooler heaters. The purpose of these coolers is to cool the molten solder and allow it to solidify.

4. Inspection: After the reflow process, the PCB should be inspected to check its functionality. This stage helps identify poor quality connections, misplaced components and shorts due to the continuous movement of the board during reflow. PCB manufacturers employ multiple inspection steps, such as manual inspection, automated optical inspection, and X-ray inspection, to check board functionality, identify lower-quality solder, and find out any potential hazards. Once inspections are complete, the assembly team will make crucial decisions. Boards with a few functional errors are usually scrapped, on the other hand, if there are minor errors, the board is sent again for rework.

5. Through-hole component insertion: Some types of PCB need to insert through-hole components together with conventional SMD components. This phase is dedicated to the insertion of such components. To do this, plated through holes are created with the aid of which PCB components carry signals from one side of the board to the other. PCB through-hole insertion typically utilizes manual or wave soldering to achieve results.

6. Final inspection: Now is the time for the second level inspection. Here, the assembled board is functionally tested, or the PCB is thoroughly inspected to monitor its electrical characteristics, including voltage, current or signal output. Today's manufacturers utilize a variety of advanced testing equipment to help determine the success or failure of a finished board.

7. Cleaning: Since the soldering process leaves a lot of flux residue in the PCB, it is critical to thoroughly clean the components before delivering the final board to the customer. To do this, wash the PCBs in deionized water. After the cleaning process, the boards are thoroughly dried using compressed air. The PCB assembly is now ready for customer inspection.

What are the advantages of PCB assembly?

Complete PCB assembly has several significant advantages for businesses of all sizes. After all the convenience of outsourcing, a critical part of making a product run smoothly is pretty big. However, when it comes to start-ups and small businesses, the advantages that come with choosing a turnkey PCB supplier can have a significant strategic impact on the business.

It will be worth it before considering some advantages. Define what a complete PCB assembly actually means. In a nutshell, PCB assembly means that the PCB supplier is responsible for every aspect of the PCB project. That means sourcing components, manufacturing and assembly. Here are some important advantages that small businesses can benefit from:

1. Save time

The clear advantage accumulated by having a turnkey manufacturer handle the entire PCB assembly is to save the client's team valuable time to focus on other aspects of the business, where their expertise lies. As a customer, you don't need to spend time and effort finding cost-effective quotes for individual components, go through the hassle of sourcing them, and then put all those quotes together. It also works well from a cost perspective, as turnkey services are priced far more efficiently than bundled services.

2. Helps you spot problems in the first place

A major advantage that arises when employing turnkey PCB assembly at the prototype stage is also that any problems can be detected early on. In fact, once you share the netlist file with the turnkey manufacturer, he will be able to point out errors, if any. These errors can then correct themselves during the design phase, rather than making costly changes after you're ready for full production, or worse, when you're already done with production and need to make changes.

3. Better management

Complete PCB assembly also has the advantage that you don't need to deal with multiple suppliers. Besides saving time, this has many other advantages. What you also save is the possibility of miscommunication when dealing with multiple suppliers. With a turnkey supplier, you may only have one point of contact, which makes the process seamless. Because delivery schedules are critical, the slightest misunderstanding between suppliers can throw an entire schedule wrong with costly consequences. With a turnkey supplier, there is peace of mind that the entire responsibility for timely delivery rests with them.

4. Other services

Turnkey suppliers often also provide other services, including inventory and sales. Shipping and more. For small businesses and start-ups, the importance of these services cannot be overstated as you don’t have to spend time, energy and manpower on them and you can keep costs under control, giving you a competitive edge.

Looking at the current commercial use of PCBA, it is like the hub of various smart appliances, without which these appliances will not work. Since the development direction of PCBA is to be applied to intelligent electronic products, it must keep pace with the times, which requires the continuous infiltration of high and new technology in research and development. Without a good research and development team, it is impossible to do this well. Shenzhen Kingford Technology Co., Ltd. is a one-stop service focusing on the intelligent manufacturing of industrial automation, automotive electronics, medical electronics, power electronics and other high-end electronic products such as PCBA and finished product assembly. More than 30 experienced R&D engineers , At the same time, it has the design and development capabilities of artificial intelligence products and smart home appliances. The company provides customers with diversified PCBA, finished product development and manufacturing services in a high-quality, efficient and fast manner, and can provide small and medium batch production.