Advantages of Rogers PCB

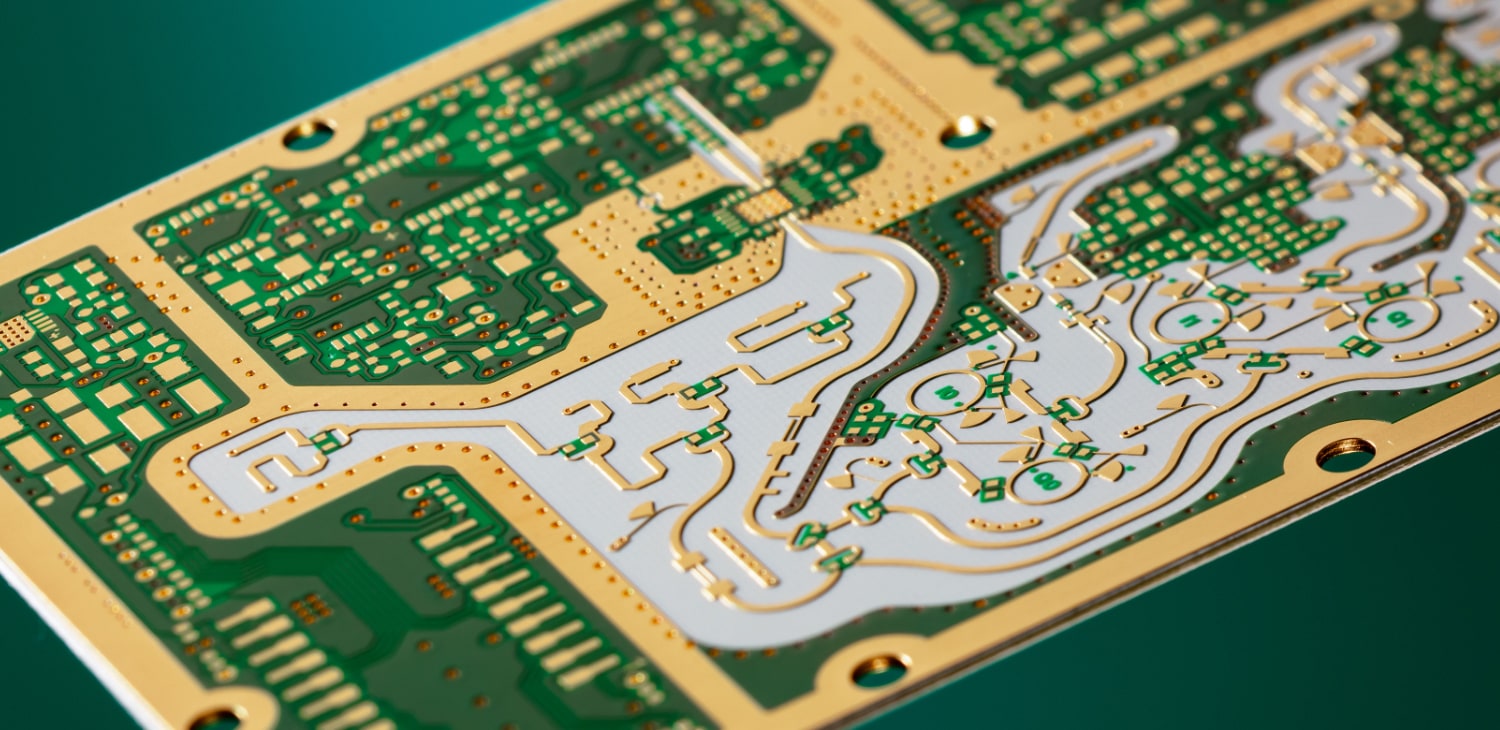

The dielectric constant (Dk:3.48+/-0.05) of Rogers (Rogers) RO4350B high-frequency sheet has strict tolerance control, and has low loss characteristics (Df:0.0037@10GHz), which is easy to mass produce CAF resistance (ion migration resistance ), RO4350B processing technology can be the same as standard epoxy resin/glass cloth. Rogers (Rogers) RO4350B high-frequency board is fully compatible with traditional PCB manufacturing technology, and does not require special pre-treatment for through-hole copper plating (PTFE board needs to be treated with plasma) or other pre-treatment processes, and the solder mask process can also be ground. . Compared with traditional microwave material laminates, the price is lower, so it is widely used in active devices and high-power radio frequency design required fire rating UL 94V-0.

Shenzhen Borui Circuits focuses on the production of microwave RF circuit boards, Rogers, Rogers, RO4350B, and high-frequency board manufacturers.

Rogers (Rogers) RO4350B high-frequency board material is a proprietary woven glass cloth reinforced ceramic filler material/hydrocarbon composite material, which combines the electrical properties of PTFE/glass cloth materials and the manufacturability of epoxy resin/glass cloth.

Rogers RO4350B has the following features:

1. Low RF loss: Df:0.0037@10GHz

2. Low dielectric constant: Dk:3.48+/-0.05 and fluctuate with temperature

3. Low Z-axis thermal expansion coefficient: 32 ppm/℃

4. Low internal expansion coefficient

5. Low dielectric constant tolerance

6. Excellent dimensional stability

7. Stable electrical characteristics at different frequencies

8. The processing technology is similar to FR-4, and it is easy to mass produce and multi-layer mixed pressure of FR4, so it has a great price competitive advantage

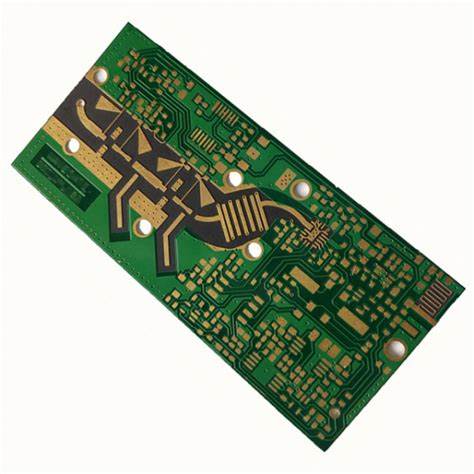

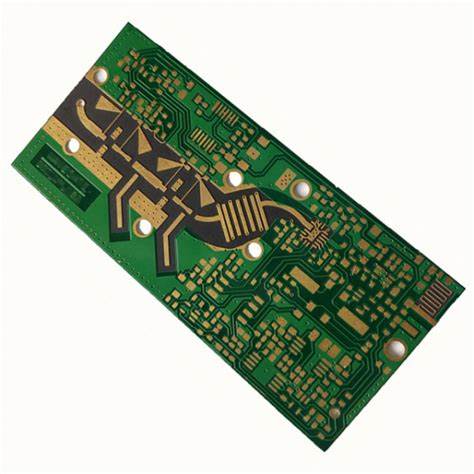

RO3003G2 is a new generation of high-frequency PCB board material for automotive radar sensor applications launched by Rogers. RO3003G2 is an enhanced version of RO3003.

RO3003G2 high frequency ceramic filled PTFE laminate is an extension of RO3003 from Rogers. Based on industry feedback, the RO3003G2 laminate specifically meets the next-generation needs of millimeter-wave automotive radar applications, and is designed for next-generation millimeter-wave automotive radar applications according to industry needs.

The optimized resin and filler content and the introduction of extremely low-profile ED copper translate to Dk of 3.00 10 GHz (clamped stripline method) and 3.07 77 GHz (microstrip differential constructive method). These laminates also exhibit very low insertion loss of 1.3dB/inch, measured by the microstrip differential construct method for 5 mil laminates.

RO3003G2 high-frequency PCB board material can be made into printed circuit boards using standard PTFE circuit board processing technology.

RO3003G2 high-frequency PCB board material has the following characteristics:

1. Adopt a brand-new very low roughness electrolytic copper foil material (VLP ED) to reduce insertion loss;

2. Combined with extremely low roughness electrolytic copper foil material and uniform structure, the dielectric constant change caused by PCB processing process is reduced;

3. Adopt advanced special filler with smaller particles, so that the circuit can design micropores with higher density/smaller diameter.

Rogers RO3003G2 high-frequency PTFE laminates are available in standard sizes: 24×18 in. (610×457 mm) and 24×21 in. (610×533.75 mm), containing 0.5 oz. (18µm) or 1.0 oz. ( 35µm) electrolytic copper foil and rolled copper foil. Available in 0.005 and 0.010 in. media thicknesses.

RO3003G2 is a new generation of high-frequency PCB board material for automotive radar sensor applications launched by Rogers. RO3003G2 is an enhanced version of RO3003.

RO3003G2 high frequency ceramic filled PTFE laminate is an extension of RO3003 from Rogers. Based on industry feedback, the RO3003G2 laminate specifically meets the next-generation needs of millimeter-wave automotive radar applications, and is designed for next-generation millimeter-wave automotive radar applications according to industry needs.

The optimized resin and filler content and the introduction of extremely low-profile ED copper translate to Dk of 3.00 10 GHz (clamped stripline method) and 3.07 77 GHz (microstrip differential constructive method). These laminates also exhibit very low insertion loss of 1.3dB/inch, measured by the microstrip differential construct method for 5 mil laminates.

RO3003G2 high-frequency PCB board material can be made into printed circuit boards using standard PTFE circuit board processing technology.

RO3003G2 high-frequency PCB board material has the following characteristics:

1. Adopt a brand-new very low roughness electrolytic copper foil material (VLP ED) to reduce insertion loss;

2. Combined with extremely low roughness electrolytic copper foil material and uniform structure, the dielectric constant change caused by PCB processing process is reduced;

3. Adopt advanced special filler with smaller particles, so that the circuit can design micropores with higher density/smaller diameter.

Rogers RO3003G2 high-frequency PTFE laminates are available in standard sizes: 24×18 in. (610×457 mm) and 24×21 in. (610×533.75 mm), containing 0.5 oz. (18µm) or 1.0 oz. ( 35µm) electrolytic copper foil and rolled copper foil. Available in 0.005 and 0.010 in. media thicknesses.