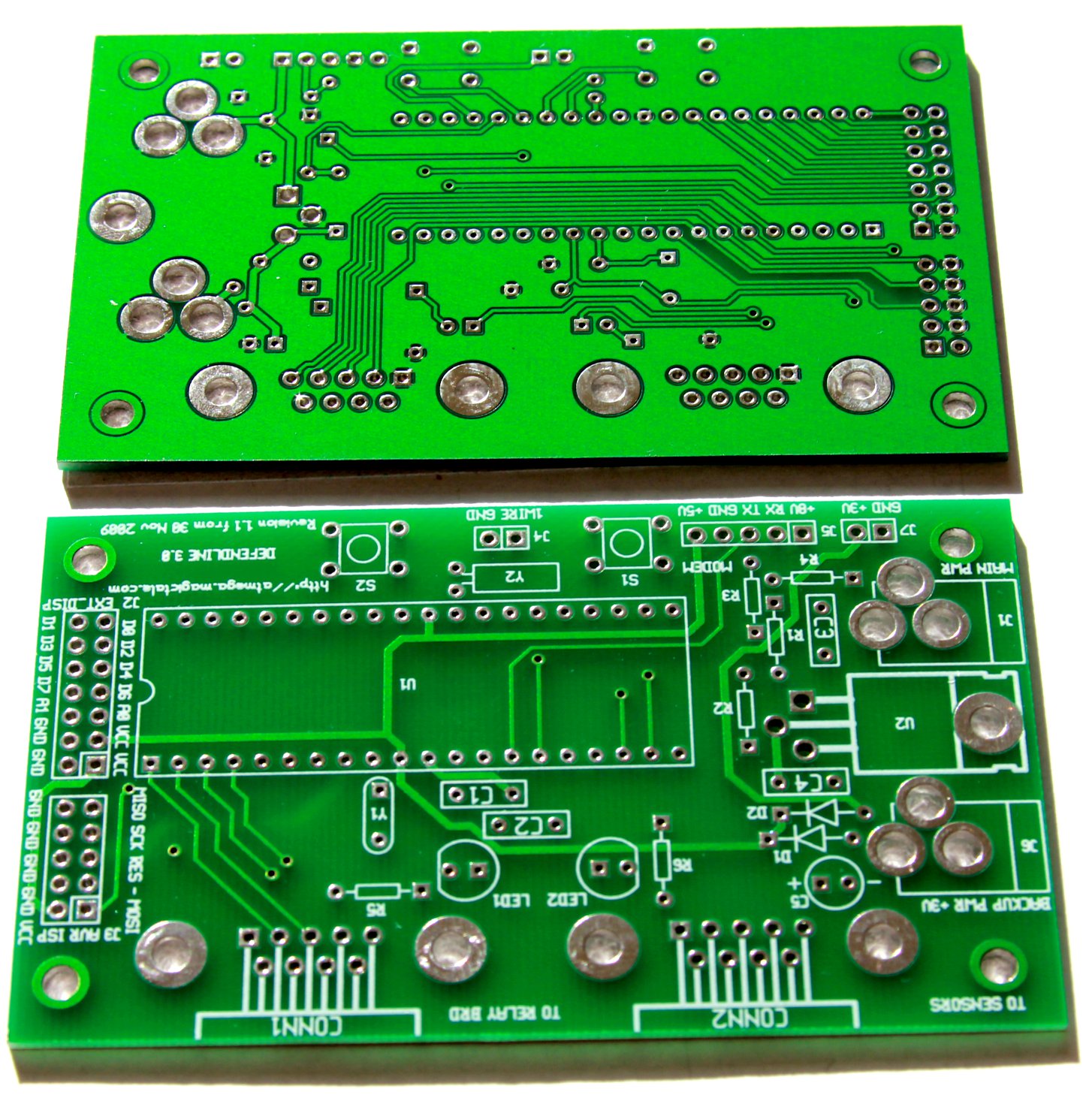

Halogen PCB circuit board

Halogen refers to the halogen elements in the periodic table of chemical elements, including fluorine (F), chlorine (CL), bromine (Br), and iodine (1). At present, flame retardant substrates, such as FR4, CEM-3, etc., are mostly brominated epoxy resins. Among brominated epoxy resins, tetrabromobisphenol A, polymerized polybrominated biphenyls, polymerized polybrominated diphenyl ethers, and polybrominated diphenyl ethers are the main anode fuels for copper clad laminates, which are low in cost and compatible with ring hydrogen resins. However, studies by relevant institutions have shown that when the halogen-containing sun-burning materials (polymerized polybrominated biphenyls PBB; polymerized polybrominated biphenyl ethers PBDE) are discarded and burned, they will release dioxin (dioxin TCDD), benzofuran (Benzfuran), etc. The amount of smoke is large, the smell is unpleasant, and the highly toxic gas is carcinogenic. It cannot be discharged after ingestion. It is not environmentally friendly and affects human health.

![PCB 산업 이해하기[3]: PCB의 종류와 공법 :: 주식하는 똥개](https://www.kingfordpcb.com/uploadfile/2023/0530/57ba3aab0558b43.jpg)

Therefore, the European Union initiated. It is forbidden to use PBB and PBDE as smoldering agents in electronic information products. The Ministry of Information Industry of China also requires that by July 1, 2006, electronic information products put on the market must not contain lead, mercury, or hexavalent. Therefore, FR4 sheets containing tetrabromobisphenol A flame retardant are not currently prohibited by law and can still be used, but they cannot be called halogen-free sheets.

What are the challenges of halogen-free PCB design?

The advantages of halogen-free boards come at the cost of increased complexity not only in the manufacturing process but also in the design. A good example is halogen-free solders and fluxes. Halogen-free varieties can sometimes alter the solder-to-flux ratio and cause scratches. This is where the solder coalesces into one large ball rather than being distributed throughout the connection. One way to solve this problem is to use solder mask to better define the pads. This curls up in the solder paste and reduces defects.

Many new materials have their own design quirks, and you may need to check with the manufacturer or do some research before using them. The number of halogen-free boards is increasing, but by no means universal. You should also talk to your CM to see if they have the capability to make PCBs with halogen free materials.

Over time, we seem to be discovering that more and more materials we use every day pose health risks to us. This is why organizations like the IEC develop standards for halogen-free boards. Remember where halogens are typically found (BFR, solvents, and insulation) so you know what to replace if you need to be halogen free. Different standards allow for different levels of halogens, and certain kinds of halogens may or may not be detected. You need to do your research beforehand to know where the problem areas are on the PCB. Once you know which material to use, it's a good idea to check with the manufacturer and CM to determine the best path forward. You may need to tweak the design or work with the CM on certain manufacturing steps to ensure your board will complete successfully.

How to detect halogenation?

In order to prove that the materials used in circuit boards do not contain halogens, manufacturers must conduct incineration tests and then use ion chromatography to determine the presence or absence of halogen elements. Brominated activator materials decompose upon combustion, in which atoms in the bromide are covalently bonded at room temperature to form bromide molecules

Test Methods:

(1) prEN 14582 Characterization of waste – Halogen and sulfur content – Oxygen combusTIon in closed systems and determine method

method A (Calorimetric bomb method)

method B (Schoniger flask combustion method)

(2) IEC 61189-2 test method for electronic materials, PCB boards, and interconnected structural parts and assemblies

part 2 TEST 2C12 test method for interconnecting structural components

(3) JPCA-ES-01-2003

Test methods for halogen-free materials

(4)IPC TM-650 (Number 2.3.41)

1.1 What is a halogen-free substrate

According to the JPCA-ES-01-2003 standard: copper clad laminates with chlorine (C1) and bromine (Br) contents less than 0.09% Wt (weight ratio) respectively are defined as halogen-free copper clad laminates. (At the same time, the total amount of CI+Br≤0.15%[1500PPM])

1.2 Why ban halogen

Halogen refers to the halogen elements in the periodic table of chemical elements, including fluorine (F), chlorine (CL), bromine (Br), and iodine (1). At present, flame retardant substrates, such as FR4, CEM-3, etc., are mostly brominated epoxy resins. Among brominated epoxy resins, tetrabromobisphenol A, polymerized polybrominated biphenyls, polymerized polybrominated diphenyl ethers, and polybrominated diphenyl ethers are the main flame retardants for copper clad laminates, which are low in cost and compatible with epoxy resins. However, studies by relevant institutions have shown that halogen-containing flame-retardant materials (polymerized polybrominated biphenyls PBB: polymerized polybrominated biphenyl ethers PBDE) will emit dioxin (dioxin TCDD), benzene furan (Benzfuran), etc. when they are discarded and burned on fire. Large amount of smoke, unpleasant smell, highly toxic gas, carcinogenic, cannot be discharged after ingestion, not environmentally friendly, and affects human health. Therefore, the European Union initiated the prohibition of using PBB and PBDE as flame retardants in electronic information products. The Ministry of Information Industry of China also requires that by July 1, 2006, electronic information products put on the market must not contain substances such as lead, mercury, hexavalent chromium, polybrominated biphenyls, or polybrominated biphenyl ethers.

EU laws prohibit the use of six substances such as PBB and PBDE. It is understood that PBB and PBDE are basically not used in the copper clad laminate industry. Bromine flame retardant materials other than PBB and PBDE are used more, such as tetrabromo Bisphenol A, dibromophenol, etc., its chemical formula is CISHIZOBr4. This type of copper-clad laminate containing bromine as a flame retardant is not regulated by any laws and regulations, but this type of bromine-containing copper-clad laminate will release a large amount of toxic gas (brominated type) when it is burned or an electrical fire occurs, and the amount of smoke is large. ;When the PCB is hot air leveled and component soldered, the board is affected by high temperature (> 200), and a small amount of hydrogen bromide will also be released; whether it will also produce dioxin is still under evaluation. Therefore, FR4 sheets containing tetrabromobisphenol A flame retardant are not currently prohibited by law and can still be used, but they cannot be called halogen-free sheets.