PCB High Voltage Clearance Guidelines

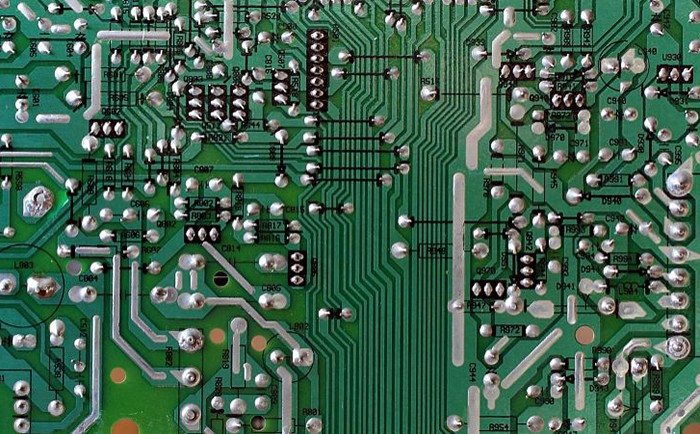

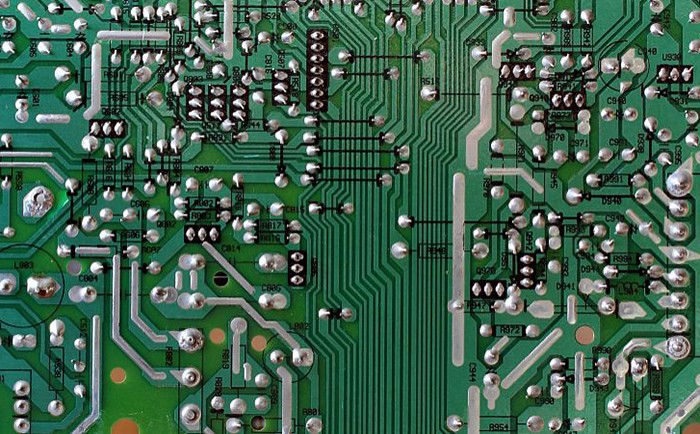

The first step in high voltage design is to determine the spacing required between components so that arcing is prevented. Simply separating components between the front and back of the board may not provide enough space between them. Also, in some cases, high voltage components may come closer to each other than the clearance allowed between high and low pressure components. The key is to use the operating voltage, expected operating environment (dust or condensation), and the board material you will be using to calculate the clearances and creepage distances you need.

Board material is critical to your calculations. When an electrical arc occurs on a circuit board, it destroys the insulating properties of the material, creating a conductive path. Some materials are more susceptible to this effect than others, and PCB laminate manufacturers use the Comparative Tracking Index (CTI) to measure this sensitivity. The higher the CTI value of a material, the better its insulation and the more suitable it is for high voltage circuits.

Once you have the correct calculations, you can use them to establish your design rules. Creating a component class for the higher voltage parts helps enforce separation between them. Here are some other helpful layout tips:

Keep in mind that some components will have metal protrusions, such as overhanging heatsinks, which will affect the gap measurement between them. These can be addressed by designing the PCB footprint accordingly or by creating specific keep-out areas.

Cutting grooves or grooves in the surface of the board also helps to increase creepage distances, as does increasing the insulation barrier.

Round or oval pads, as opposed to rectangular pads, will help increase the gap between them.

Keep power traces short, thick, and as straight as possible. Using specific information from a calculator or a trace width table is essential here.

Be sure to specify the best possible surface finish and conformal coating to protect the board from assembly debris. Solder or other metal debris on the surface of the board increases the potential for high voltage arcing.

At this point, you will need data for clearance and creepage calculations, which we will explore next.

Get the High Voltage Design Information You Need

Different clearance and creepage distance calculators are available online to find the correct clearance for your high voltage PCB layout. You will also need to consult the manufacturer of the PCB laminate to determine the CTI value for the PCB material you are considering. It will also help to use different standards covering high voltage layout, creepage distance and clearance criteria, which are given in the current PCBA manufacturing standard IPC-A-610:

IPC-2221: Generic standard covering design rules, including high voltage spacing.

IPC-9592: A standard specifically for high-voltage power conversion equipment.

UL-61010-1: Safety Standard for Testing and Laboratory Equipment Design.

UL-60950-1: Broad standard for high and low voltage equipment.

Get the High Voltage Design Information You Need

Different clearance and creepage distance calculators are available online to find the correct clearance for your high voltage PCB layout. You will also need to consult the manufacturer of the PCB laminate to determine the CTI value for the PCB material you are considering. It will also help to use different standards covering high voltage layout, creepage distance and clearance criteria, which are given in the current PCBA manufacturing standard IPC-A-610:

IPC-2221: Generic standard covering design rules, including high voltage spacing.

IPC-9592: A standard specifically for high-voltage power conversion equipment.

UL-61010-1: Safety Standard for Testing and Laboratory Equipment Design.

UL-60950-1: Broad standard for high and low voltage equipment.

When does PCB design security require specific spacing rules?

Not every PCB design has the same strict rules as the spacing required for high voltage PCB designs. In general, if your product's normal operating voltage is at or above 30 VAC or 60 VDC, then you should be very diligent about the spacing rules in your board design. If you have a high-density board, especially a high-voltage board, you need to pay more attention. High density makes spacing trickier and more important for protection.

Spacing is even more important in high voltage designs because the voltage on board components makes it easier for arcing between two conductive components to occur on your PCB. Any arcing that does occur presents a higher risk to the product and the user. To help reduce risk, there are two primary spacing measurements in PCB design, clearance and creepage.

What is PCB Design Clearance?

Clearance is the shortest distance between two conductors through air. I remember it being defined in terms of clearance clearance; how much space there is in the air before my head hits something. If the gap anywhere on the PCB is too small, an overvoltage event could create an arc between adjacent conductive elements on the board.

Clearance rules vary with PCB material, voltage and environmental conditions. The environmental impact is very significant. Most commonly, humidity changes the breakdown voltage of the air and affects the likelihood of arcing. Dust is another standard factor, as particles that collect on the surface of a PCB can form tracks over time, shortening the distance between conductors.

Arcing can damage your product and your users, so board clearance is a critical design parameter.

What is PCB design creepage distance?

Similar to clearance, creepage distance measures the distance between conductors on a PCB. However, instead of measuring distance in air, it measures the shortest distance along the surface of an insulating material. Board material and environment can also affect creepage distance requirements. Moisture or particulate buildup on the board can reduce creepage distances the same as when cleared.

Creepage can be a difficult requirement when you are designing with high density. Since moving rails is rarely the first choice, there are a few other tricks for increasing surface distance in your design. Creepage distances can be increased significantly without changing the trace layout on the board by adding slots or vertical isolation barriers between the tracks.

Consider the Comparative Tracking Index (CTI of your material)

After working voltage, the most important factor in clearance and creepage requirements comes from the material properties of the PCB. The electrical insulation of a material is indicated by a "comparative tracking index" or CTI value. Expressed as a voltage, CTI is determined by a standard test that measures when a failure occurs on the surface of a material.

There are 0 to 5 categories according to the breakdown value of the material. The mandatory insulation ratings for products are based on these CTI categories. Category 5 is the lowest, with values less than 100 V. For 600+ V faults, Category 0 has the most robust and often expensive material options.

PCB insulator materials have different breakdown voltages and corresponding product application safety categories.

What should I do? Know what material and spacing to use?

With so many variables in PCB design and material selection, your best bet for meeting safety requirements and standards is to go straight to the source. There are two standards that I refer to most often. The first is IPC-2221, which is a common standard for PCB design clearance and creepage guidance. The second is IEC-60950-1 (Edition 2). The IEC version is the standard you want to read for any IT product that has AC mains or battery power, especially if you want to sell these products internationally.