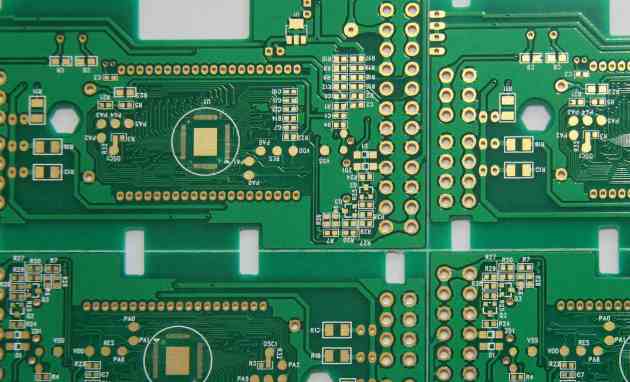

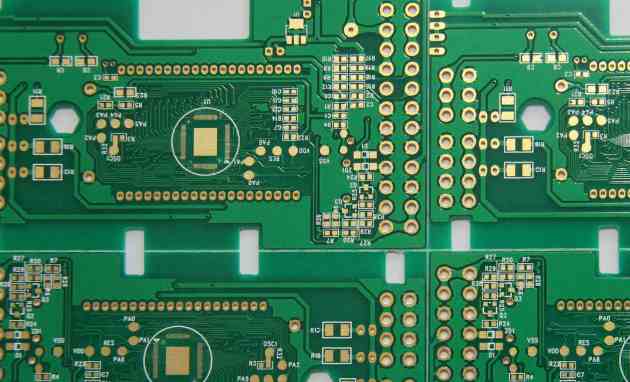

The automatic dispensing machine is dispensing on the PCB circuit board, which is a desktop packaging device. Like all packaging equipment, PCB automatic dispensing machines are automated machines with precise fluid control technology. The biggest advantage of PCB packaging equipment is its ability to achieve continuous uninterrupted point filling operation of PCB boards.

When using automatic dispensing machine for automatic dispensing, there are many problems that need to be paid attention to. The first is the viscosity of the glue, the insufficient viscosity of the glue will cause the package bond is not strong; The proportion of glue is too large and there will be the appearance of dragging. Secondly, the removal of glue bubbles is also a required course before packaging operations, which requires the joint efforts of operators and packaging equipment technology. At present, the fully automatic dispensing machine equipment on the market has been able to solve this problem well.

The dispensing of PCB is used in a wide variety of automatic packaging equipment, and the desktop automatic dispensing machine is undoubtedly the most widely used one. PCB dispensing machine with its stable control system, accurate positioning has become an emerging force in the desktop packaging equipment market.

With the development of economy and technological innovation, the application field of automatic dispensing machine has been further expanded. The development of automatic dispensing machine technology, whether it is for packaging equipment manufacturers or packaging application enterprises, is beneficial and harmless, and is a win-win change. The use of automatic dispensing machine equipment has greatly improved the production efficiency of enterprises, and the product quality has more protection than the manual dispensing period. For packaging manufacturers, the needs of the application industry are the source of technological innovation for manufacturers

Reasons and solutions for plugging of electronic patch nozzle during SMT patch processing

SMT offset adhesive series products can meet the needs of customers in the SMT production of adhesive, high bond strength to the chip; It has excellent heat resistance and meets the process requirements of reflow welding and wave soldering. High wet strength; Good storage stability. We provide our customers with products suitable for various sizing processes. Scraping products have good gluing properties, suitable for manual, semi-automatic, automatic scraping and thick mesh scraping processes.

The glue nozzle may be blocked during the dispensing process of red glue

Reason: incompatible glue cross contamination; The inside of the pinhole is not completely clean; The residual glue in the pinhole has anaerobic curing phenomenon. The size of the patch particle is not uniform.

Solution: Replace the rubber nozzle or clean the needle hole and sealing ring of the rubber nozzle; Clean the nozzle, be careful not to squeeze the solidified residual glue into the nozzle (such as the beginning and end of each tube of glue); Do not use brass or copper dispensing tips (acrylic adhesive patches have anaerobic curing properties in nature); Choose a patch with uniform particle size.

SMT chip manufacturers talk about anti-static SMT loading and unloading rack specifications

Anti-static SMT loading and unloading rack has been introduced to you before, it is specially used for automatic loading machine, specifications and styles are generally universal. The specifications of the anti-static SMT loading and unloading rack are as follows:

1. Upper and lower metal base plate, gear track adjustment design, easy operation; Size is 535*460*570mm, can put 50 pieces of PCB board, the use of PCB board specifications: 535*mm. Specifications of side guide grooves: 3.5mm deep, 5mm wide, and 10mm pitch.

2, upper and lower metal bottom plate, gear track adjustment design, easy to operate; Size is 535*530*570mm, can put 50 pieces of PCB board, the use of PCB board specifications: 535*mm. Specifications of side guide grooves: 3.5mm deep, 5mm wide, and 10mm pitch.

3, upper and lower metal bottom plate, gear track adjustment design, easy to operate; Size is 460*400*563mm, can put 50 pieces of PCB board, the use of PCB board specifications: 460*mm. Specifications of side guide grooves: 3.5mm deep, 5mm wide, and 10mm pitch.

4, the upper and lower metal bottom plate, screw adjustment design, can enter the aging room; Size is 460*400*563mm, can put 50 pieces of PCB board, the use of PCB board specifications: 460*mm. Specifications of side guide grooves: 3.5mm deep, 5mm wide, and 10mm pitch.

5, the upper and lower metal bottom plate, screw adjustment design, can enter the aging room can withstand high temperature 200 degrees; The size is 355*320*563mm, can put 50 pieces of PCB board, the use of PCB board specifications: 350*mm. Specifications of side guide grooves: 3.5mm deep, 5mm wide, and 10mm pitch.

6, the upper and lower metal bottom plate, gear track adjustment design, can withstand high temperature 80-200 degrees; The size is 355*320*563mm, can put 50 pieces of PCB board, the use of PCB board specifications: 350*mm. Side plate guide groove specifications: groove depth 3.5mm groove width 10mm. This is the most conventional model in the industry, is widely used.

7, up and down plastic bottom plate, screw adjustment design, can withstand high temperature 80-120 degrees; The size is 355*315*580mm, can put 50 pieces of PCB board, the use of PCB board specifications: 350*mm. Specifications of side guide grooves: 3.5mm deep, 5mm wide, and 10mm pitch.

8. Upper and lower plastic bottom plate, gear track adjustment design, easy operation; The size is 355*320*563mm, can put 50 pieces of PCB board, the use of PCB board specifications: 350*mm. Specifications of side guide grooves: 3.5mm deep, 5mm wide, and 10mm pitch.