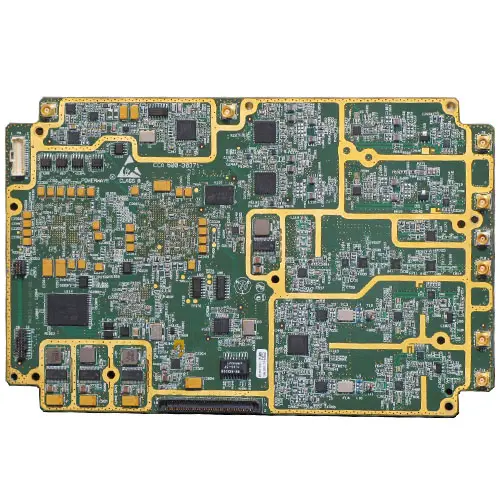

Compliant with IATF, ISO, IPC and UL standards. 99.9% product pass rate including online SPI, AOI and X-Ray.

Rigid-flex to rigid-flex PCB assembly uses leaded and lead-free solder.

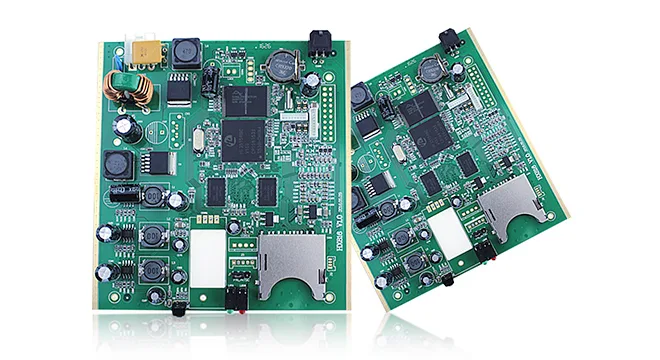

We have 10 SMT mounting lines and 6 DIP/finished product assembly lines.

It will be shipped in 4 to 48 hours after board mounting is completed.

We have reliable parts suppliers.

We provide 24/7 live sales and technical support.

- PCB Assembly Services+-

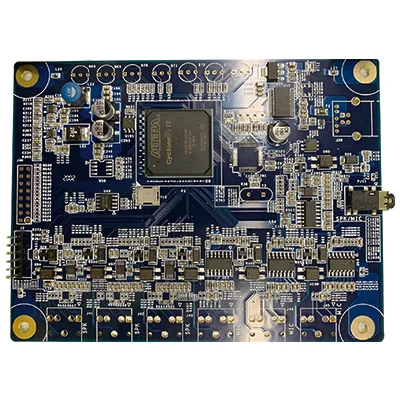

- BGA Assembly

- SMT Assembly

- LED PCB Assembly

- Rigid-Flex PCB Assembly

- Turnkey PCB Assembly

- Prototype PCB Assembly

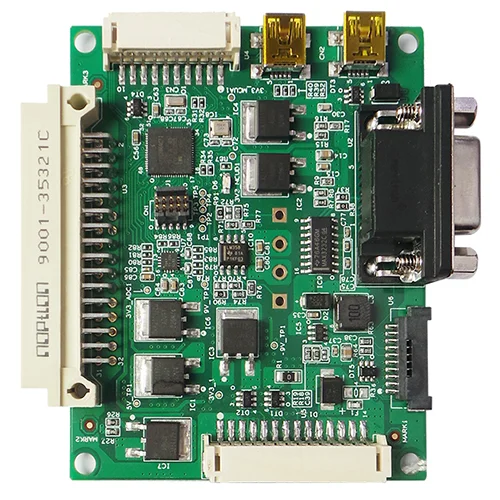

- Through Hole PCB Assembly

- Low Volume PCB Assembly

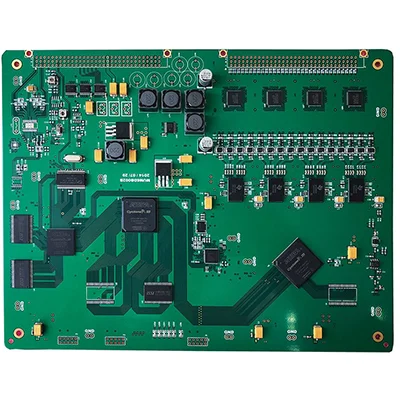

- High Volume PCB Assembly

- Hybrid PCB Assembly

- Single-sided PCB assembly

- Double-Sided PCB Assembly

- SMT chip processing

- DIP plug-in processing

- Medical PCB Assembly

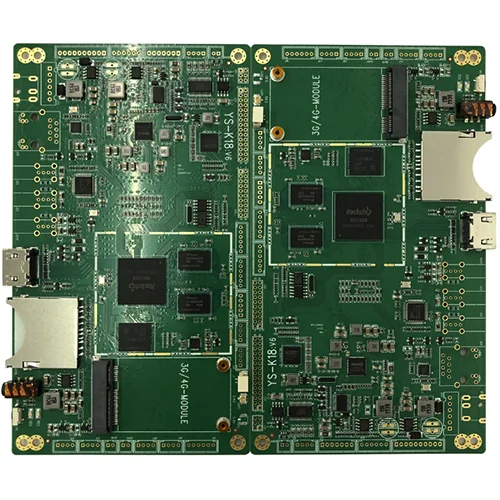

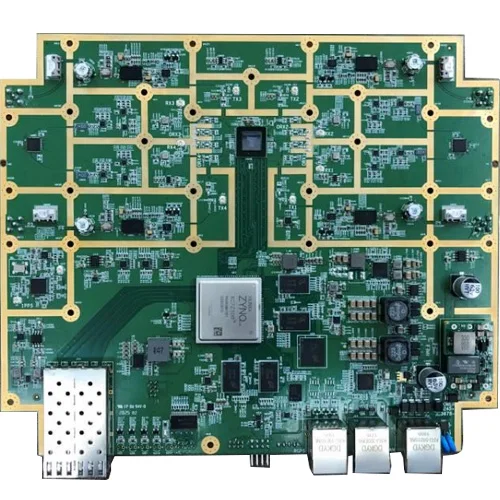

- Industrial PCB Assembly

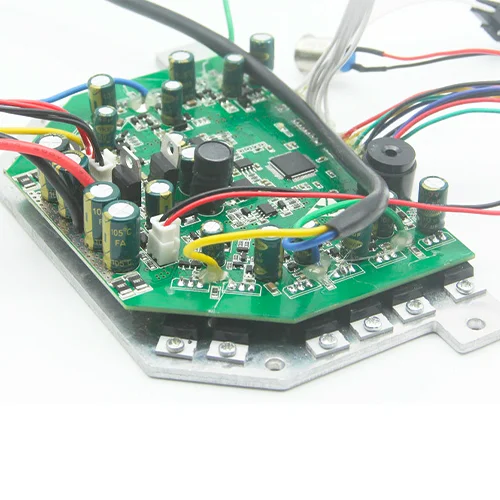

- Consumer Electronics PCBA

- Automotive Electronics PCBA

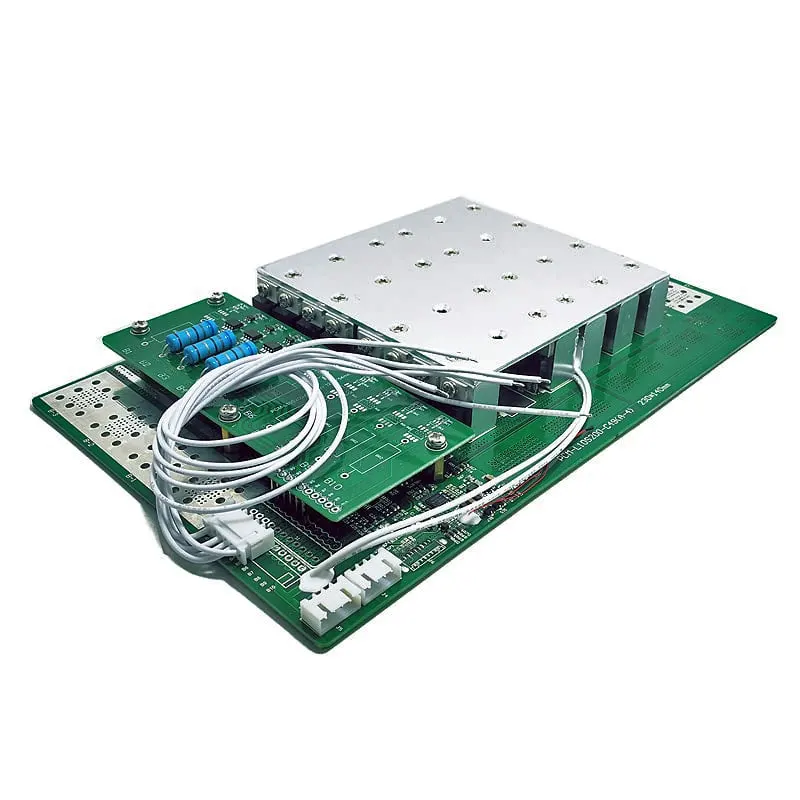

- Energy Storage Module PCBA

- Military Applications PCBA

- PCB Manufacturing Services+-

- Electronic Design Services+-

- Standard PCB Design

- HDI PCB Design

- Multilayer PCB Design

- PCB Reverse Engineering

- High speed PCB Design

- High Power PCB Design

- High Voltage PCB Design

- Amplifier PCB Design

- Gold Fingers PCB Design

- Impedance Control PCB Design

- Rigid Flex PCB Design

- Halogen Free PCB Design

- LED PCB Design

- RF PCB Design

- Metal Core PCB Design

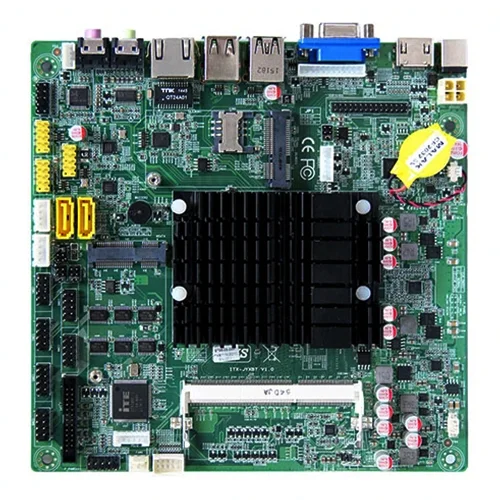

- Finished Product Assembly

- Components Purchasing

- DFMA Services

- Finished Product Test

China PCB Fabrication&PCBA Assembly Manufacturer-Kingford PCB Assembly Factory, Sourcing of parts+Lead-Free Crest + Post-Weld + Check.One-Stop PCB Assembly Services. High Precision Manufacturing Facility. SMT Capacity: 19 Million Points/Day, Monthly Production Capacity Can Reach 150,000 to 300,000 Sets/Month.

- PCB Assembly Equipment

- PCB Assembly Capability

Automatic solder paste printing machine

AOI Optical Inspection

SMT high-speed placement machine

Nitrogen reflow soldering

x-ray

Three anti-paint spraying machine

SPI Solder Paste Thickness Tester

Automatic wave soldering machine

first article inspection

| SMT capacity: 19 million points/day | ||

| Testing Equipment | X-RAY Nondestructive Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station | |

| Placement speed | Chip placement speed (at best conditions) 0.036 S/piece | |

| Mounted Component Specifications | Pasteable smallest package | |

| Minimum device accuracy | ||

| IC type chip accuracy | ||

| Mounted PCB Specifications | Substrate size | |

| Substrate thickness | ||

| throw rate | 1. Resistance-capacitance ratio 0.3% | |

| 2. IC type without throwing material | ||

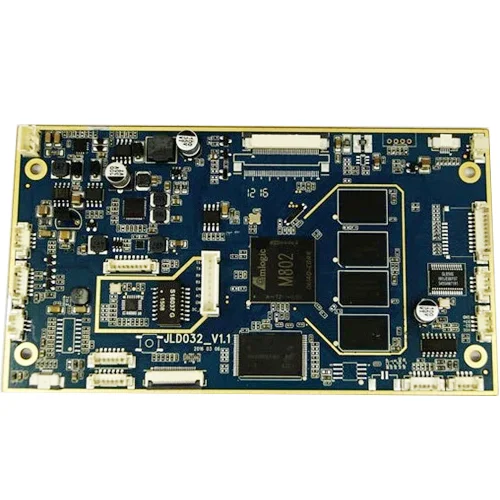

| Board Type | POP/common board/FPC/rigid-flex board/metal substrate | |

| DIP daily production capacity | ||

| DIP plug-in production line | 50000 points/day | |

| DIP post welding production line | 20000 points/day | |

| DIP test production line | 50000pcs PCBA/day | |

| Assembly processing capability | ||

| The company has more than 10 advanced assembly production lines, dust-free and anti-static air-conditioning workshop, TP dust-free workshop, equipped with aging room, test room, functional test isolation room, advanced and perfect equipment, can carry out various product assembly, packaging, testing, Aging, etc. production. Monthly production capacity can reach 150,000 to 300,000 sets/month | ||

| PCBA processing capability | ||

| project | Mass processing capability | Small batch processing capability |

| Number of layers (max) | 2-18 | 20-30 |

| Plate type | FR-4, Ceramic Sheet, Aluminum Base Sheet PTFE, Halogen Free Sheet, High Tg Sheet | PTFE, PPO, PPE |

| Rogers,etc Teflon | E-65, ect | |

| Sheet mixing | 4 layers - 6 layers | 6th floor - 8th floor |

| biggest size | 610mm X 1100mm | / |

| Dimensional Accuracy | ±0.13mm | ±0.10mm |

| Plate thickness range | 0.2mm--6.00mm | 0.2mm--8.00mm |

| Thickness tolerance ( t≥0.8mm) | ±8% | ±5% |

| Thickness tolerance (t<0.8mm) | ±10% | ±8% |

| Media thickness | 0.076mm--6.00mm | 0.076mm--0.100mm |

| Minimum line width | 0.10mm | 0.075mm |

| Minimum spacing | 0.10mm | 0.075mm |

| Outer copper thickness | 8.75um--175um | 8.75um--280um |

| Inner layer copper thickness | 17.5um--175um | 0.15mm--0.25mm |

| Drilling hole diameter (mechanical drill) | 0.25mm--6.00mm | 0.15mm--0.25mm |

| Hole diameter (mechanical drill) | 0.20mm--6.00mm | 0.10mm--0.20mm |

| Hole Tolerance (Mechanical Drill) | 0.05mm | / |

| Hole tolerance (mechanical drill) | 0.075mm | 0.050mm |

| Laser Drilling Aperture | 0.10mm | 0.075mm |

| Plate thickness aperture ratio | 10:1 | 12:1 |

| Solder mask type | Photosensitive green, yellow, black, purple, blue, ink | / |

| Minimum Solder Mask Bridge Width | 0.10mm | 0.075mm |

| Minimum Solder Mask Isolation Ring | 0.05mm | 0.025mm |

| Plug hole diameter | 0.25mm--0.60mm | 0.60mm-0.80mm |

| Impedance tolerance | ±10% | ±5% |

| Surface treatment type | Hot air leveling, chemical nickel gold, immersion silver, electroplated nickel gold, chemical immersion tin, gold finger card board | Immersion Tin, OSP |