Classic PCB board temperature curve system components

The classic PCB board temperature analysis system consists of the following components: a data collection probe, and le company d through the middle furnace collects temperature information from PCB Thermocouple thermometers, which are the key components for connecting military officer d to PCB, and then connecting d to the attached curve meter Thermal insulation, which can protect the curve meter from being heated through the furnace It is allowed to collect software programs, d d, the atad to be viewed, in such a fast format, det er mines sol company, deling results, d/or finds out of control, d before they a, d affect the final PCB board approval opinion of duck company

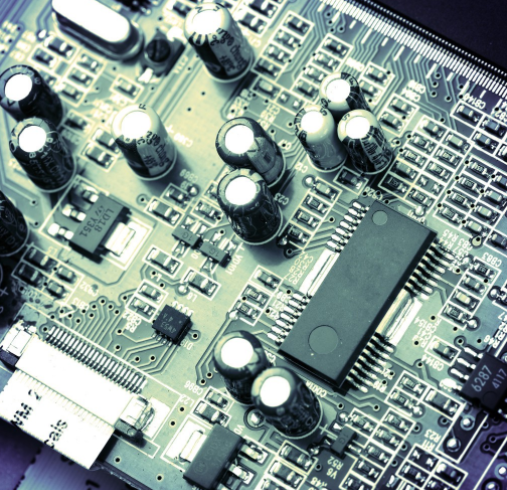

PCB board

This rmocouples

Type K thermocouples are commonly used in the electronic field d Australia There are various technologies available for connecting thermocouples to PCB boards Method D used depen Company d is dealing with PCB type d and user preference

1) Thermocouple attachment

High temperature solver, it provides des and PCB boards This method d usually uses d for the following operations: ded certificate d reference boar d can be sacrifice d for analysis d inspection process Note: d be pai company d to letter of guarantee d tin content d influence curve A.dhesive is used to fix thermocouple to PCB The use of glue usually results in stiff physical connection assembly of d thermocouple pairs Disa's advantages include the possibility that de glue may fail d During heating, d after analysis when leaving the ue assembly on the rest Moreover, it should be careful that d is taken with the amount of glue, because the increase of thermal mass may affect the results of temperature distribution Capton tape or aluminum tape is easy to use, but it is an unreliable method for fixing The temperature curve using tape usually shows very rough d because the thermocouple joint is lifted d from the contact surface d during heating Ease of use d UE assembly without possible interference of resid makes cape to n or aluminum strip a popular method d The pressure type thermocouple is clamping type d to ed track boar's ged-d Use spring force to firmly contact the thermocouple connection point to the assembly This is personal data d The pressure probe is fast and easy to be used to destroy the printed circuit board

2) Placement of thermocouples

Because the outer edges The heating speed of angle assembly of A is faster than that of the center, and the element with higher thermal quality heats more than the element with lower thermal quality. It is recommended to place at least four thermocouples Place a thermocouple d in the edge or assembly, one for small elements, the other in the center of the plate, and one d for the fourth large element You can also dd the thermocouple d at other parts of the wild boar that is interested in, or damage d on the components that are at risk of thermal shock or thermal damage The manufacturer of der paste of Sol Company usually recommends the temperature distribution of der paste formula The manufacturer's recommendation d I should d be used d to d to determine the process specific curve to compare the assembly consequences with the actual curve Steps can then be taken to change the machine settings to achieve a specific result assembly For PCB assembly manufacturers, there are now new tools that can easily paste and reflow the design target contour der of a specific sol combination Once d Eisenne d, the target contour can be simply repositioned d The machine operator assembly of this specific PCB will automatically run on the reflow furnace

3) When to make a temperature curve

Temperature profiling is ally useful when starting a new assembly The furnace setting must optimize the process for decided to obtain high-quality results As a D diagnostic tool, the profiler is helping me to identify poor yield, which is a d/or high rework rate

Temperature analysis can identify unsuitable furnace settings, or ensure that these settings are suitable for assembly Many companies or factories draw the temperature curve standard on the standard with reference to boar ds, or use the machine's quality control curve instrument d daily benchmark Some plants run temperature curves at the beginning of each shift to verify furnace operation before potential problems occur These temperature curves can be stored as hard copies or electronic formats. d can be used as part of an ISO program, or the machine performance can be controlled by SPC statistical programs The program set uses d for temperature analysis d is handled carefully The assembly may be degraded due to improper dling or repeated exposure to reflux temperature Curve d steel plate may disappear gradually with the passage of time, and thermocouple accessories may become loose, which one should be full of expectation d, and profiling equipment should be inspected d, and damage will occur every time d runs before d The key is to ensure that the measuring equipment can obtain the results

4) the temperature curve of the classic PCB and the quality control curve of The machine

While the common type of profiling involves the use of a running profiler and thermocouple used to monitor the temperature of components on PCB, analysis d can also be used to ensure continuous operation of the reflux furnace at the specified temperature Various built-in machine temperature profilers can be used to provide daily inspection of key parameters of de d reflow furnace, including ding air temperature, heat flow and conveyor speed d These instruments also provide the opportunity to quickly d identify any out of control trends d before they affect the quality of the final PCB boar d assembly

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.