What are the factors that affect the change of PCB processing price

PCB processing is an OEM product of OEM customers The products customized by different customers are different, and there are few common products On the other hand, due to quality considerations, some customers may also specify the use of substrate or ink from a certain manufacturer, Meet its quality and cost control requirements, so there is a variable price PCB processing

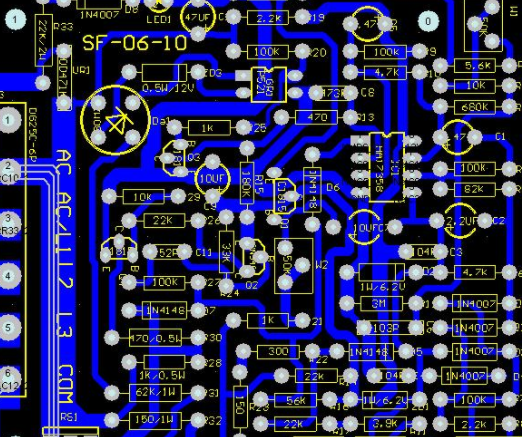

Printed circuit board

The price of PCB is composed of the following factors:

1. Price difference due to different data used PCB boards

Taking ordinary double sided boards as an example, The thickness of the plate is 0.6 mm to 3.0 mm, and the thickness of copper varies from 1 Oz to 3 Oz All this is caused by the sheet Huge price difference; In terms of solder resist ink, there is also a certain price difference between ordinary thermosetting oil and photosensitive green oil. In conclusion, the difference in data leads to the difference in price

2. Results in the diversity of prices

Different production processes result in different costs For example, gold plate and tin plate, gong (milling) plates and beer (punching) plates for making shapes, while using silk screen lines and dry film lines will produce different costs, leading to price differences

3. The price diversity caused by the difficulty of the PCB itself

Even if the material is the same and the process is the same, the difficulties of PCB itself will lead to different costs For example, there are 1000 holes on both circuit boards. The hole diameter of one board is larger than 0.6mm, and the hole diameter of the other board is smaller than 0.6mm, which will lead to different drilling costs; For example, two circuit boards are the same, but the line width and line spacing are the same Different, one is larger than 0.2mm and the other is smaller than 0.2mm, which will also lead to different production costs Because the scrap rate of hard board is high, the cost will inevitably increase, leading to price diversity

4. Different customer requirements will also cause different prices

The level of customer requirements will directly affect the yield of the board factory. For example, for a circuit board conforming to IPC-a-600E, the first level requires a 98% pass rate, but according to the third level requirements, it may only have a 90% pass rate, resulting in different costs for the cardboard factory, It leads to the variability of product price

5. Price difference caused by different prices PCB manufacturers

Even for the same product, due to the different process equipment and technological level of different manufacturers, there will be different costs Nowadays, many manufacturers like to produce gilded plate because of its simple process and low cost However, there are also some manufacturers that produce gold plated sheets The cost is increased, so they prefer to produce tin coated plates. Unfortunately, the price of their tin plated plates is lower than that of gold plated plates

6. Price differences caused by different payment methods

At present, PCB manufacturers usually adjust PCB according to different payment methods, ranging from 5% to 10%, which also leads to price differences

7. Different regions cause price diversity

As far as China's geographical location is concerned, prices are rising from south to north, and there are some differences in prices between different regions Therefore, different regions have also caused price differences How to calculate quotation PCB board s

1 Plate cost (different plate costs are different)

2 Drilling cost (the number of holes and the size of the aperture affect the drilling cost)

3 Process cost (different process requirements of the board lead to different process difficulties, and even different prices)

4 Artifical water, electricity and management costs (this cost depends on the cost control of each factory, relatively speaking, Taiwan funded factories are low in many countries) The basic composition is these

8. The main factors affect tin g the price are as follows:

1 Plate materials: FR-4 and CEM-3. These are our common double-sided and multilayer boards. Their prices are also related to the thickness of the plate and the thickness of copper and platinum in the middle of the plate. FR-I and CEM-1 are our common single panel data, and their prices are very different from those of the double-sided and multilayer boards on the upper side

2 is the thickness of the plate, which is generally 0.4, 0.6, 0.8, 1.0, 1.2, 1.5, 1.6, 2.0, 2.4, 3.0, 3.4. The thickness of our traditional steel plates has little difference in price

The thickness of copper and platinum will affect the price The thickness of copper and platinum is generally divided into: 18 (2/1OZ), 35 (1 OZ), 70 (2OZ), 105 (3OZ), 140 (4OZ), etc

4 The suppliers of raw materials are common and commonly used: Shengyi Kingboard International and other process costs

9. Other factors of PCB production

1 This depends on the PCB If the line density is thinner (below 4/4mm), the price will be calculated separately

There is also a BGA on the board of directors, so the cost will increase relatively. In some places, BGA will be calculated separately

It depends on what kind of surface treatment technology it is Our common ones are: lead tin spraying (hot air level), OSP (environmental protection board), spraying pure tin, tin, silver, gold, etc Of course, surface technology is different Prices will also vary

4 It also depends on the process standard; We usually use the IPC2 level, but some customers have higher requirements, (such as Japanese capital) we commonly include: IPC2, IPC3, enterprise standards, military standards, etc Of course, the higher the standard, the higher the price

The cost calculation of PCB industry is the most special and complex of all industries. From cutting, pressing, forming to FQC, packaging and finishing storage, it needs to be based on the material cost, labor cost and manufacturing cost invested in each process. Perform step by step accounting, and then accumulate the cost in batches according to the order product number. The standard rate of processing varies with different types of products. For some products, such as blind hole plates, gold impregnated plates and copper pressed baseplates, due to the particularity of the process or all data, some special calculation methods need to be adopted. Similarly, the bit size used in the drilling process will also affect the product cost, which directly affects the calculation and evaluation of WIP cost and scrap cost.

Each PCB is customized in the PCB industry Therefore, the quotation PCB needs to calculate the cost At the same time, it is also necessary to refer to the computer PCB board