What is a high Tg circuit board?

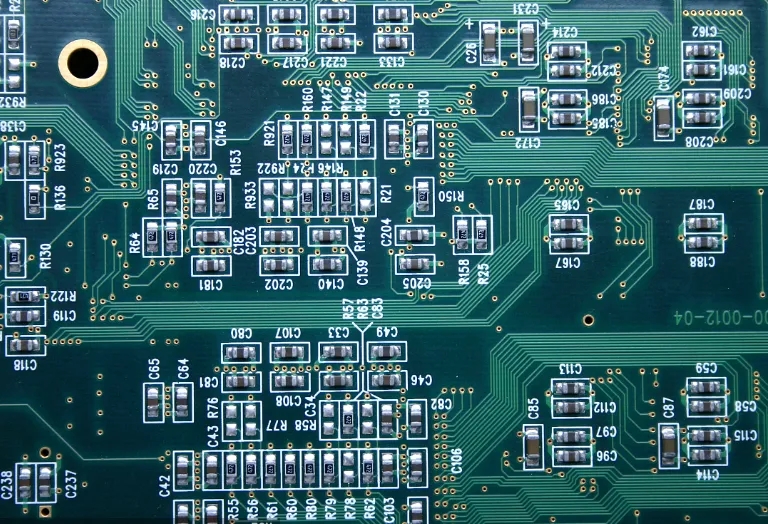

High Tg circuit boards in smt chip plants help equipment exposed to extreme temperatures and harsh environments. These include mobile phones, jet engines and auto parts in smt processing. Mobile phone manufacturers spend a lot of time choosing materials that enable their mobile phone components to withstand their operating conditions. These materials must be able to withstand the impact, vibration and heat they may face.

High TG materials in smt chip factories offer several advantages. For example, high TG materials can increase the continuous operating temperature of the circuit board and allow higher current. These advantages promote the PCB industry to use Hi TG materials. However, before deciding to use Hi TG circuit board in smt chip, several things should be considered first.

High Tg circuit boards are designed for use with high temperature, humidity and irritating chemicals. Therefore, these circuit boards in smt processing factories are helpful to prolong the service life of electronic equipment. High Tg pcb is an ideal choice for multi-layer electronics and high-power equipment. They also reduce the risk of short circuits and increase functionality.

Compared with ordinary PCBs, the advantages of high Tg PCBs include better mechanical strength, dimensional stability, adhesion and reduced moisture absorption. In addition, the high Tg circuit board is heat resistant, moisture resistant, chemical resistant, and has high resistance to electric shock. This material can also reduce the heat generated by multilayer or high-density circuits.

RoHS regulations are pushing the printed circuit board industry to high Tg circuit boards. For high power density designs that require lead-free solder, these PCBs are the only viable option. High Tg PCBs can also reduce heat generation, affecting weight, power requirements, and size.

High Tg PCBs contribute to extreme environments and equipment, such as jet engines, missiles, and automotive parts. For example, mobile phone suppliers spend a lot of time choosing the best materials for their phones because components must be able to withstand vibration and shock. Therefore, the use of high Tg circuit boards has grown exponentially in recent years.

High Tg PCBs are usually made of glass fiber reinforced plastic. The Tg value of the circuit board is about 20 to 25 degrees higher than the expected operating temperature. When the material is heated beyond this point, it will become glassy, resulting in unstable mechanical structure and electrical performance. Therefore, high Tg PCBs should be flame retardant.