PCB materials commonly used in industrial applications

Industrial PCB data:

The selection of PCB materials is a very important step in PCB manufacturing.

This is because the strength and flexibility of data directly affect the quality of PCB.

The resistance and heat resistance of PCB materials commonly used in industrial applications must be extremely high.

This is because industrial applications generate heat after a long stroke.

If the heat resistance of the data is low, the PCB may be deformed.

In general, the data of the printed circuit board shall enable all layers of the printed circuit board to have strength, and the traces and signal paths can be easily etched on the board.

The most commonly used information in industry PCB manufacturing is glass fiber and polytetrafluoroethylene

FR-4 glass fiber:

The base plate of industrial PCB is usually made of glass fiber of FR4 material. FR stands for flame retardant. FR4 has very high tensile strength.

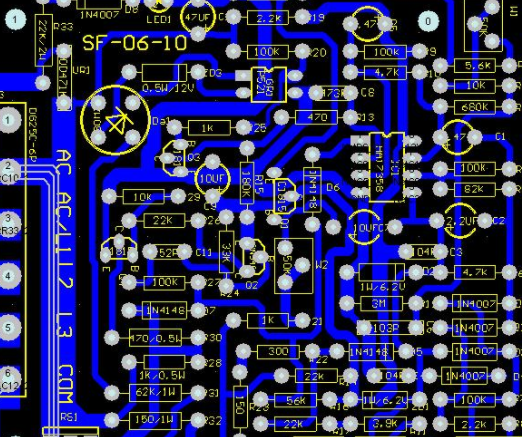

Circuit board

These materials provide:

Good dimensional stability

Excellent insulation and power efficiency

Moistureproof property

Excellent combustion index

FR4 data is one of the good choices for industrial PCB manufacturing. This information is used to reinforce the PCB base.

teflon:

Polytetrafluoroethylene is also called polytetrafluoroethylene or polytetrafluoroethylene. Fluoropolymers are plastics with many properties.

The basic characteristics of PTFE make it an interesting material for manufacturing industrial PCB:

It has excellent chemical resistance

Good electrical insulation in high temperature and humid environment, suitable for industrial environment

Good heat resistance and low temperature resistance.

Resistant to light, UV and inclement weather.

Low friction coefficient

Low loss factor/dielectric constant

Strong non stick performance.

Flexibility

It has good fatigue resistance under low stress conditions.

Low water absorption

Metal:

One of the main parts of manufacturing industrial PCB is the use of traditional metals, such as copper, aluminum, and iron.

Because of its superconductivity, this kind of information is the first choice for manufacturing industrial PCB, and these types of information also help to apply surface mount technology in the assembly process.

We know that this material is durable, so when we use it in PCB manufacturing, the obtained PCB will be durable.

Most PCB manufacturers use aluminum backplanes to maintain the highest quality.

Ceramic PCB:

Ceramics are a good choice for manufacturing industrial PCB.

The basic characteristics of ceramics make them interesting materials for manufacturing industrial PCB:

High hardness

High elastic modulus

Low ductility

High dimensional stability

Good wear resistance

High corrosion resistance and chemical corrosion resistance.

High weather resistance

High melting point

High operating temperature

Low thermal expansion

Medium low thermal conductivity

Good electrical insulation

However, because ceramics are very expensive, it is impossible to use them in all industrial applications.

It should be remembered that different types of materials are used for manufacturing industrial PCB, and they all have different advantages and disadvantages.

When manufacturing, we must select the data according to the application requirements.

Quality:

PCB manufacturers must maintain the quality of materials used in PCB manufacturing.

Because high-quality PCBs allow you to replace or replace components without any problems without damaging other components on the board.

High quality PCBs are durable and do not need to be replaced repeatedly in industrial applications.

Cost:

The cost of industrial PCB depends on several factors. If you prefer gold foil to solder, it will be very expensive for you.

Similarly, the cost of circuit boards using blind and/or buried tracks is significantly higher than that of typical multilayer circuit boards with the same number of layers.

Even row/wide spacing can lead to cost differences. If a pitch greater than 6mm is selected, the cost will be higher than 6mm.

Energy and heat:

Heat capacity is an important factor in industrial PCB materials.

Does the usefulness of PCB depend on this factor? The reliability of the system PCB can also be determined based on this factor

In addition, we need to know the rate at which data power (watts) is converted to temperature.