PCB coating standard and giant magnetoresistance effect

Standard for surface coa (tin) g (plating) coating of PCB

From the process and inspection of PCB pad welding components, the standards for PCB pad surface coating (electroplating) mainly include the following five aspects.

-Heat resistance

The surface coating (plating) coating can still protect the copper surface of the PCB circuit board pad from air oxidation and allow the soldering material to enter the copper (or metal) surface to establish a connection The heat resistance of organic surface coating (plating) refers to the performance of its melting point and thermal decomposition (volatility) temperature. but its thermal decomposition the temperature (350 ° C) should be much higher than the measuring point temperature and welding temperature of the welding material to ensure that The copper surface does not generate air oxidation during melting The heat resistance of metal surface coating does not have this problem

-Coverage

For the organic heat-resistant solderable coating (including flux), it can completely cover the surface of the copper solder pad before and during welding, without being oxidized and polluted by air. Only when the molten solder is welded to the surface of the copper solder pad, it can swim, decompose and volatilize, and float (cover) on the surface of the solder joint.

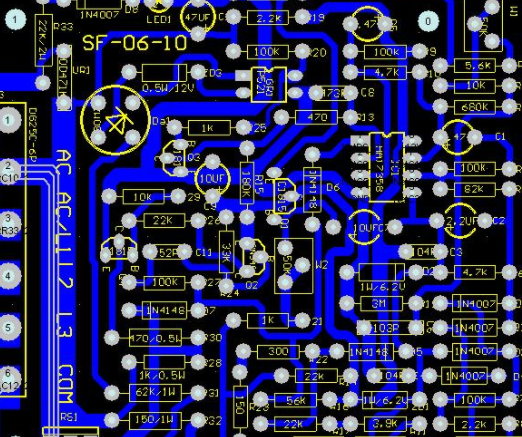

Circuit board

Therefore, in order to ensure that the melted welding materials are completely welded on the coupling plate, the surface tension of the melted organic surface coating must be low and the decomposition temperature must be high to ensure good coverage before and during welding At the same time, its specific gravity is much smaller than that of the molecule solver material (tin) to ensure that the molecule solver material squeezes and Penetrates the copper surface Therefore, the coverage of organic surface coating refers to its temperature at welding temperature Surface tension, specific gravity and other properties During welding, the coating on the metal surface is partially melted into the welding material or on the surface of the barrier layer to establish the connection

Remains

The residue of organic heat-resistant solderable coating (plating) refers to the residue of welding materials on the pad or solder joint after welding. Under normal circumstances, these residues are harmful (such as organic acids or halides) and should be removed. In addition, cleaning measures should be taken after welding. At present, there is no clean welding technology, because the organic surface coating (electroplating) has few residues after welding (most of which have been decomposed and volatilized).

-Corrosivity

The corrosivity of organic heat-resistant solderable coating (electroplating) refers to the corrosion of welding materials on PCB surface after welding, such as the corrosion of PCB substrate surface and metal layer. This is because the organic heat-resistant solderable coating (electroplating) contains more or less halides or organic acids (mainly to further clean the residual oxides and pollutants on the copper pad), but the presence of acidic substances after welding is dangerous. In addition to decomposition and volatilization, it must also be cleaned and removed.

– Environmental protection

The environmental protection of PCB surface coating (electroplating) refers to that the waste slag generated in the process of coating establishment and the waste liquid from cleaning after welding should be easy to handle, low cost and not pollute the environment.

Analysis of Giant Magnetoresistance Effect and Layer Structure of PCB

The so-called giant magnetoresistance effect refers to the phenomenon that when there is an external magnetic field, the resistivity of the data changes significantly compared with that when there is no external magnetic field It is generally defined as GMR=where (H) is the resistance of the material under the action of the magnetic field H (0) refers to the resistance of the material without the action of an external magnetic field The huge change in the resistance of some magnetic materials caused by an external magnetic field (called the giant magnetic effect) is an important content in magnetic electronics There are many kinds of giant magnetoresistance data with giant magnetoresistance effect at room temperature, such as multilayer giant magnetoresistance data, particle giant magnetoresistance data, oxide giant magnetoresistance data, tunnel junction magnetoresistance data

The so-called magnetoresistive effect refers to the phenomenon that the resistance of a conductor or transistor changes under the action of a magnetic field. Giant magnetoresistance effect is caused by Peter Gr à ¼ It was independently discovered by nberg and Albert Fert in 1988., They jointly won the 2007 Nobel Prize in Physics. It is found that in magnetic multilayers such as Fe/Cr and Co/Cu, the ferromagnetic layer is separated by non-magnetic materials with nanometer thickness. Under some conditions, the reduction of resistivity is considerable, about 10 times that of ordinary magnetic metals and alloys. This phenomenon is called "giant magnetoresistance effect"

The giant magnetoresistance effect can be explained by quantum mechanics. Each electron can spin, and the scattering rate of the electron depends on the spin direction and magnetization direction of the magnetic material. The spin direction is the same as the magnetization direction of the magnetic material. The electron scattering rate is low. More electrons pass through the magnetic layer, which shows a low impedance. On the contrary, when the spin direction is opposite to the magnetization direction of the magnetic material, the electron scattering rate is high, and there are fewer electrons passing through the magnetic layer, which shows a high impedance.

The sensor based on the giant magnetoresistance effect of PCB mainly has three layers of sensing data: the reference layer or the pinning layer, Normal Layer and Free Layer (The giant magnetoresistance effect often referred to as Free references to the resistance of raw material) When there is an external magnetic field, there is a significant change compared with the absence of an external magnetic field It is commonly defined as GMR=where (H) is the resistance of the PCB data under the action of the magnetic field H (0) means that there is no external magnetic field Low resistivity of raw materials the huge change in the resistance of some magnetic materials caused by an additional magnetic field (called The giant magnetic effect) is an important content in magnetic electronics Giant magnets with giant magnetoresistance effect have many types of resistance raw materials at this stage at room temperature, such as multilayer giant magnetoresistance raw materials, granular giant magnetoresistance raw materials, oxide giant magnetoresistance raw materials, tunnel junction magnetoresistance raw materials, etc

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.