PCB engineer's detailed explanation of PCB design based on EMC

0 Introduction

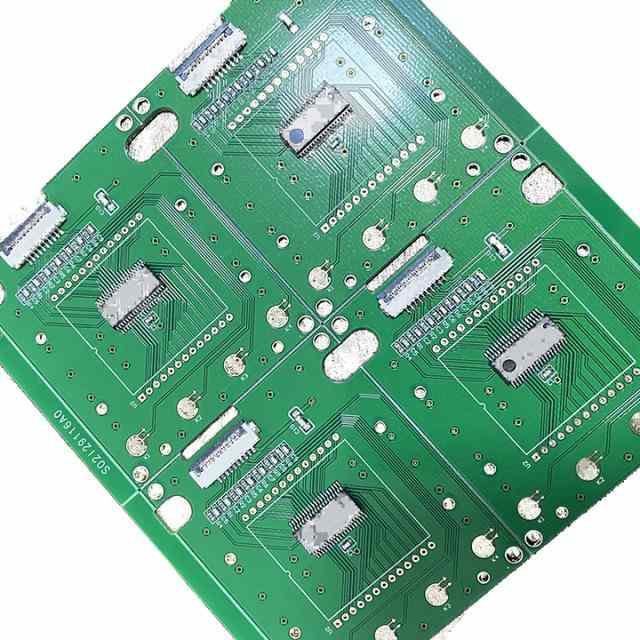

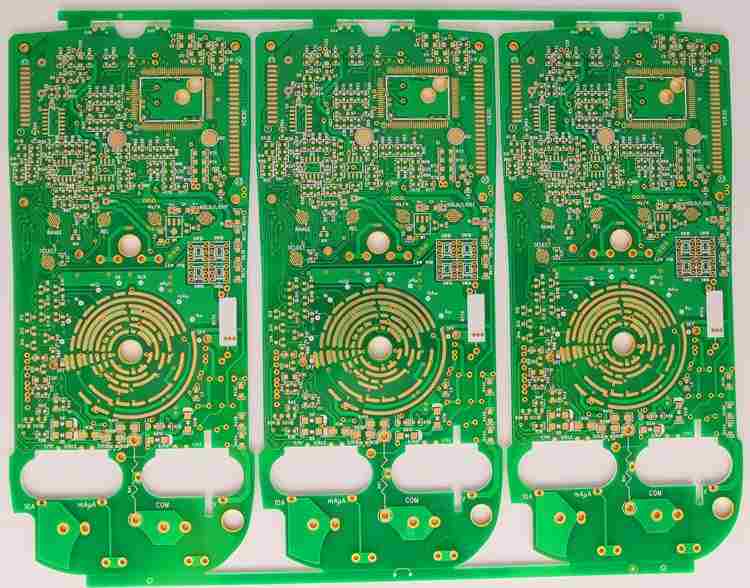

PCB is the abbreviation of printed circuit board in English. Generally, printed circuit refers to the conductive pattern made of printed circuit, printed components or both on insulating materials according to predetermined design. The conductive pattern that provides electrical connection between components on insulating substrate is called printed circuit. In this way, the printed circuit or the finished board of the printed circuit is called the printed circuit board, also called the printed board or the printed circuit board. PCB is indispensable to almost all electronic devices we can see, ranging from electronic watches, calculators and general-purpose computers to computers, communication electronic devices, aviation, aerospace and military weapon systems. As long as there are integrated circuits and other electronic components, PCB is used for electrical interconnection between them. Its performance is directly related to the quality of electronic equipment. With the rapid development of electronic technology, electronic products tend to be more and more high-speed, high sensitivity and high density. This trend has led to the serious problem of electromagnetic compatibility (EMC) and electromagnetic interference in PCB design. EMC design has become an urgent technical problem in PCB design.

1 Electromagnetic compatibility

Electromagnetic Compatibility (EMC) is a new comprehensive discipline, which mainly studies electromagnetic interference and anti-interference. Electromagnetic compatibility refers to that under the specified electromagnetic environment level, the electronic equipment or system will not reduce its performance index due to electromagnetic interference, at the same time, the electromagnetic radiation generated by them will not exceed the limited limit level, will not affect the normal operation of other systems, and will achieve the goal of mutual interference free and reliable work between equipment and systems. Electromagnetic interference (EMI) is caused by electromagnetic interference sources transferring energy to sensitive systems through coupling paths. It includes three basic forms: conduction by wires and public ground wires, space radiation or near-field coupling. Practice has proved that even if the circuit schematic diagram is correctly designed and the printed circuit board is improperly designed, the reliability of electronic equipment will be adversely affected, so ensuring the electromagnetic compatibility of the printed circuit board is the key to the whole system design.

1.1 Electromagnetic interference (EMI)

When an EMI problem occurs, it needs to be described by three elements: interference source, propagation path and receiver.

Therefore, if we want to reduce electromagnetic interference, we need to find ways to deal with these three elements. Now we mainly discuss the wiring technology of printed circuit board.

2 Wiring technology of printed circuit board

Good PCB wiring is a very important factor in EMC.

2.1 Basic characteristics of PCB

A PCB is composed of a series of laminating, routing and prepreg treatments on the vertical stack. In multilayer PCB, the designer will lay the signal line on the outermost layer for convenience of debugging.

The wiring on PCB has impedance, capacitance and inductance characteristics.

Impedance: The impedance of the wiring is determined by the weight of copper and cross-sectional area. For example, an ounce of copper has an impedance of 0.49 m Ω/unit area. Capacitance: The capacitance of the wiring is determined by the insulator (EoEr), the current range (A) and the wiring spacing (h). The equation is expressed as C=EoErA/h, Eo is the dielectric constant of free space (8.854 pF/m), Er is the relevant dielectric constant of PCB substrate (4.7 in FR4 rolling).

Inductance: The inductance of the wiring is evenly distributed in the wiring, about 1 nH/m.

For 1 ounce copper wire, under the rolling condition of 0.25 mm (10 mil) thick FR4, a wire 0.5 mm (20 mil) wide and 20 mm (800 mil) long above the ground layer can produce an impedance of 9.8 m Λ, an inductance of 20 nH and a coupling capacitance of 1.66 pF with the ground. Comparing the above values with the parasitic effects of components, these are negligible, but the sum of all wiring may exceed the parasitic effects. Therefore, the designer must take this into account. General guidelines for PCB wiring:

(1) Increase the distance between wires to reduce the crosstalk of capacitive coupling;

(2) Parallel distribution of power lines and ground wires to optimize PCB capacitance;

(3) Place sensitive high-frequency wires away from high noise power lines;

(4) Widen the power line and ground wire to reduce the impedance of the power line and ground wire.

2.2 Segmentation

Division refers to the physical division to reduce the coupling between different types of lines, especially through power lines and ground wires.

An example of dividing 4 different types of circuits with the dividing technique. On the ground plane, non-metallic trenches are used to isolate the four ground planes. L and C are used as filters for each part of the board to reduce the coupling between power supply surfaces of different circuits. High speed digital circuits are required to be placed at the power supply inlet because of their higher instantaneous power demand. Interface circuits may require devices or circuits for electrostatic discharge (ESD) and transient suppression. For L and C, it is better to use different values of L and C instead of one large L and C, because it can provide different filtering characteristics for different circuits.

2.3 Decoupling between local power supply and IC

Local decoupling can reduce noise propagation along the mains. The large capacity bypass capacitor connected between the power input port and the PCB acts as a low-frequency ripple filter and serves as a potential storage to meet the sudden power demand. In addition, there should be decoupling capacitors between the power supply and the ground of each IC. These decoupling capacitors should be as close to the pins as possible. This will help filter the switching noise of the IC.

2.4 Grounding technology

Grounding technology is applied to both multi-layer PCB and single-layer PCB. The goal of grounding technology is to minimize the grounding impedance, thereby reducing the potential of the grounding loop from the circuit back to the power supply.

(1) Ground wire of single layer PCB

In a single layer (single side) PCB, the width of the grounding wire should be as wide as possible and at least 1.5 mm (60 mil). Since star wiring cannot be realized on a single layer PCB, the change of jumper and ground wire width should be kept to a minimum, otherwise the line impedance and inductance will change.

(2) Grounding wire of double-layer PCB

In double-layer (double-sided) PCB, ground grid/lattice wiring is preferred for digital circuit, which can reduce ground impedance, ground loop and signal loop. As in single layer PCB, the width of ground wire and power wire shall be at least 1.5 mm. Another layout is to place the ground plane on one side and the signal and power lines on the other side. In this arrangement, the grounding circuit and impedance will be further reduced, and the decoupling capacitor can be placed as close as possible to the IC power supply line and the ground plane.

(3) Protective ring

The protection ring is a grounding technology that can isolate the noisy environment (such as RF current) outside the ring, because no current flows through the protection ring in normal operation.

(4) PCB capacitance

On the multilayer board, PCB capacitance is generated by the thin insulating layer separating the power supply surface from the ground. On a single layer board, the parallel laying of power lines and ground wires will also lead to this capacitive effect. One of the advantages of PCB capacitor is that it has very high frequency response and low serial inductance that is evenly distributed on the whole surface or the whole line. It is equivalent to a decoupling capacitor uniformly distributed on the whole board. No single discrete component has this feature.

(5) High speed circuit and low speed circuit

The high-speed circuit shall be arranged closer to the ground, while the low-speed circuit shall be arranged closer to the power supply surface.

(6) Copper filling of ground

In some analog circuits, the unused circuit board area is covered by a large ground to provide shielding and increase decoupling capability. However, if the copper area is suspended (for example, it is not connected to the ground), it may act as an antenna and cause electromagnetic compatibility problems.

(7) Ground plane and power plane in multilayer PCB

In multilayer PCB, it is recommended to place the power supply surface and ground plane as close as possible in adjacent layers, so as to generate a large PCB capacitance on the whole board. The key signal with the fastest speed shall be near the side of the ground, and the non key signal shall be placed near the power supply surface.

(8) Power requirements

When the circuit requires more than one power supply, each power supply shall be separated by grounding. However, multi-point grounding is impossible in a single layer PCB. One solution is to separate the power cord and ground wire from other power cords and ground wires. This also helps to avoid noise coupling between power supplies.

3 Conclusion

The methods and techniques introduced in this paper are conducive to improving the EMC characteristics of PCBs. Of course, these are only a part of the EMC design. Usually, the interference caused by reflected noise, radiated emission noise, and other technological problems should also be considered. In the actual design, the PCB with good EMC performance should be designed according to the design objective requirements and design conditions, using reasonable anti electromagnetic interference measures.