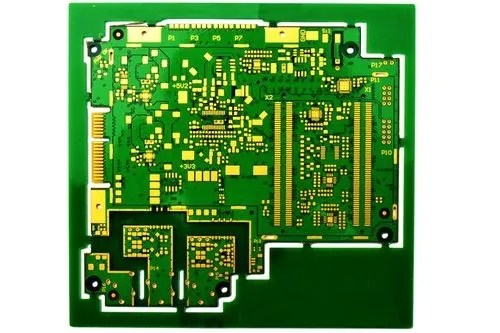

PCB design and fabrication requirements shall be clear with respect to plate, plate thickness, copper thickness, process, solder resistance/character color, etc. The above requirements are the basis for making a board, so RD engineers must write clearly. From the customers I have contacted, Gree has done a relatively good job,

1 Fabrication requirements

The PCB plate, plate thickness, copper thickness, process, solder resistance/character color, etc. shall be clear. The above requirements are the basis for making a board, so the R&D engineer must write clearly. From the customers I have contacted, Gree has done a relatively good job. The technical requirements of each document are very clear, even if we usually think that the most normal white characters with green solder resist ink are written in the technical requirements, while some customers do not write anything, so they send it to the manufacturer for proofing, In particular, some manufacturers didn't write out some special requirements, so the first thing they did after receiving the email was to consult with the requirements in this regard, or some manufacturers did not meet the requirements in the end.

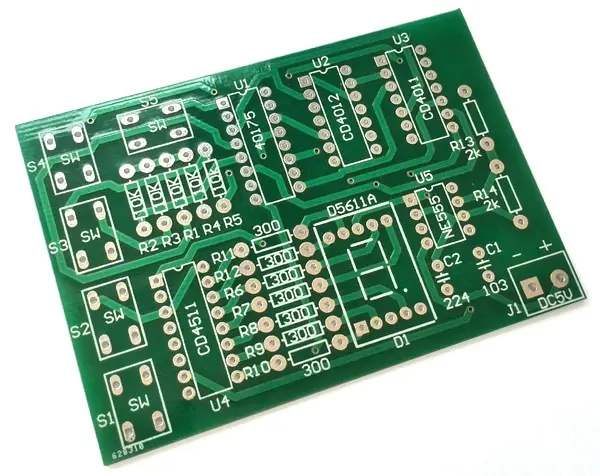

2 Design of drilling

The most direct and biggest problem is the design of the minimum hole diameter. Generally, the minimum hole diameter in the plate is the hole diameter of the through hole, which is directly reflected in the cost. Some plates can be designed with a hole of 0.50 mm, that is, only 0.30 mm, so the cost will directly rise significantly. The manufacturer will increase the price if the cost is high; In addition, there are too many vias. Some DVDs and digital photo frames are really full of vias. There are 1000 vias at any time. There are too many boards made in this area. I think it should be 500-600 holes normally. Of course, some people will say that there are advantages in the signal conduction and heat dissipation of the board due to the number of vias. I think it is necessary to take a balance to control these aspects without raising the cost, Let me give you an example: our company has a customer who makes DVDs in Shenzhen, and the volume is very large. This was also the case at the beginning of the cooperation. Later, the cost was really a big problem for both parties. Through communication with R&D, we tried to increase the aperture of the vias as much as possible, and removed some vias on the large copper sheet. For example, the heat sink in the middle of the main IC was replaced by four 3.00MM holes, so that the cost of drilling was reduced, One square meter can reduce the drilling cost by tens of dollars, which is a win-win for both parties; In addition, some slot holes, such as 1.00MM X 1.20MM ultra short slot holes, are really difficult for manufacturers to do. First, it is difficult to control the tolerance. Second, the slot from the second drill is not straight, and some of them are bent. We have done some of these boards before. As a result, for the boards with a few cents, a deduction of $1/yuan was made because the slot holes are not qualified. We also communicated with customers about this problem, Later, the 1.20MM round hole was directly used.

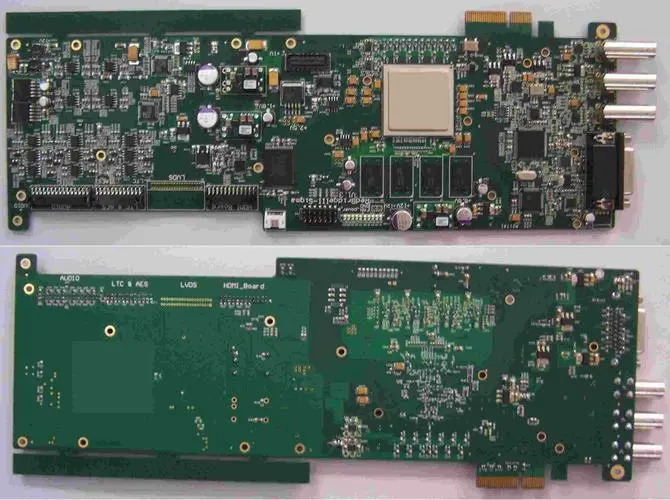

3 Line design

For the line width and line spacing, as well as open and short circuits, it is the most common for manufacturers. Apart from the special ones, I think the larger the line width and line spacing is, of course, the better. I have seen some documents. A line that could have walked straight must have several bends in the middle. Several lines in the same row have the same width and size, but the spacing is different. For example, the spacing in some places is only 0.10 mm, while in some places it is 0.20 mm, I think R&D should pay attention to these details when wiring; Some circuit pads or wires are only 0.127MM away from the large copper sheet, which increases the difficulty for the manufacturer to handle the film. It is better to route the pads more than 0.25MM away from the large copper sheet; The safe distance between some PCB wiring and the periphery or V-CUT is very small, so the manufacturer can move it well, while some PCB wiring must be designed by R&D before it can be done. Some PCB wiring is not even connected to the same network, while some PCB wiring is obviously connected to the same network, but it is not connected. Finally, the manufacturer communicated with R&D, and found that it was a short circuit and an open circuit, and then the data must be modified. This is not rare, Experienced engineers may be able to see that those who are inexperienced only follow the design documents. As a result, they either modify the documents for re proofing or use a blade to scrape or fly wire. For boards with impedance requirements for the circuit, some R&Ds do not write, and finally do not meet the requirements. In addition, the vias of some plates are designed on the SMD PAD, and tin leaks down during welding.

4 Design of PCB resistance welding

The problems that are easy to occur in the resistance welding are the exposure of copper on some copper sheets or wires. For example, the resistance welding window should be added on the copper sheet to facilitate heat dissipation, or the copper should be exposed on some high current wiring lines. Generally, these additional resistance welding are placed on the Soldermask layer, but some R&D are placed on a new layer, on the mechanical layer, and on the prohibited wiring layer. There are five flowers and eight doors, all of which are available. This is not mentioned, not specifically stated, and it is difficult to understand. I think it is best to put it on the TOP Soldermask or BOTTOM Soldermask layer, which is the easiest to understand. In addition, it is necessary to explain whether the green oil bridge in the IC should be retained.

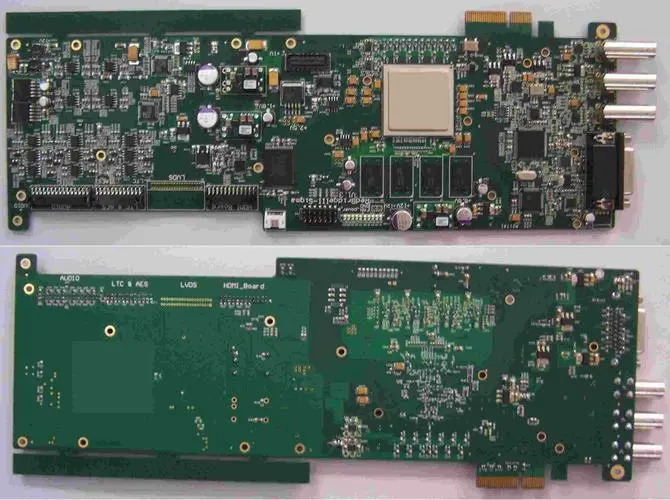

5 Character design

The most important thing about characters is the design requirements of character width and character height. Some boards are not very good in this aspect. The same component even has several character sizes. As a PCB manufacturer, I think it is not beautiful. I think it is necessary to learn from those PCB main board manufacturers. The same size of component characters row by row makes people look pleasing. In fact, it is better to design characters above 0.80 * 0.15MM, and it is also easier for manufacturers to print silk screen; In addition, some large white oil blocks, such as those on the crystal oscillator or some row inserts, some manufacturers need to cover the pad with white oil, and some need to expose the pad, which must also be explained; I have also encountered some silk screen position exchange errors, such as the character exchange of resistance and capacitance, but these errors are still rare; There are also marks that need to be added, such as UL mark, ROHS words, PB mark, manufacturer's LOGO and number.

6 Design of appearance

The current boards are rarely rectangular and irregular, but there are mainly several kinds of lines and frames, which are hard to choose. In addition, in order to improve the utilization of equipment (such as SMT), V-CUT has to be assembled, but the space between the assembled boards is different, some have space, some have no space. It is good to sample for the first factory in batches. If you want to change suppliers later, it will be troublesome, If the second factory does not match the first one, the steel mesh will not be covered. Therefore, in no special circumstances, it is better not to spell space; In addition, some pcb file designs may draw a small rectangular hole into the slot hole to be drilled and place it on the shape layer. This situation is common in PROTEL software design files. PADS is relatively good. It is believed that the hole is placed on the shape layer, which is easily misunderstood by manufacturers as punching out or making NPTH attributes. For some PTH attributes, it is easy to cause problems.