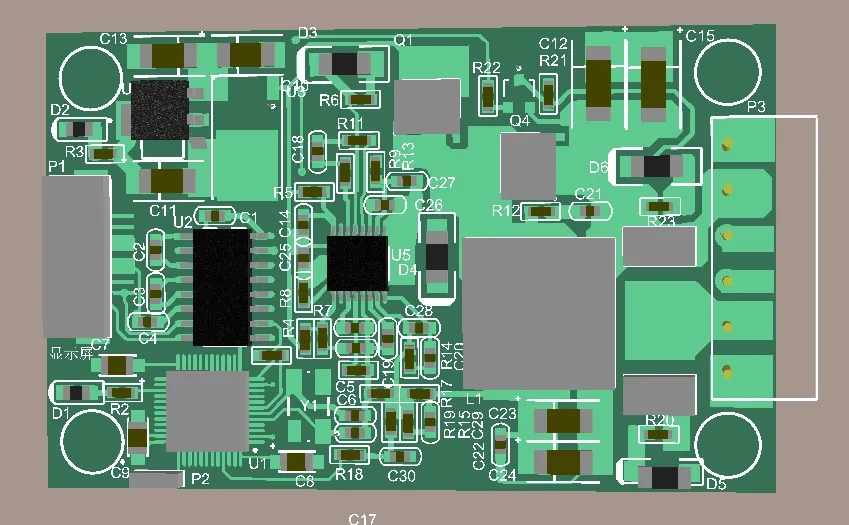

S-TouchTM Capacitive Touch Controller PCB Layout Guide

The purpose of this application guide is to provide design layout guidance for the structure and layout of various PCBs (printed circuit boards) (such as FR4, flexible PCBs or ITO panels) used in S-TouchTM capacitive touch sensing design.

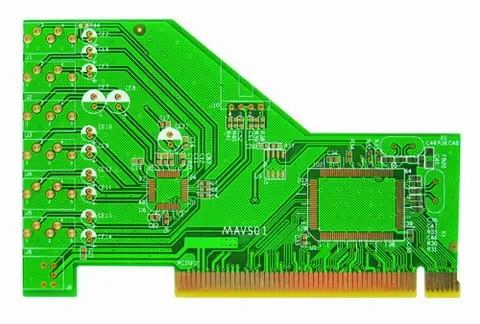

FR4 is the most commonly used PCB substrate available in the market. FR4 is a glass fiber reinforced epoxy resin laminate, and PCB can be single-layer or multi-layer.

When the size of the touch module is limited, it is not always possible to use a single layer PCB. Generally, four or two layers of PCB are used. We will take the most commonly used two-layer PCB as an example to introduce PCB layout guidelines.

PCB design and layout

In a two-layer PCB, the S-TouchTM touch controller and other components are laid on the bottom layer of the PCB, and the sensor electrodes are laid on the top layer of the PCB.

The tuning matching capacitor required for each sensor channel can be directly arranged at the bottom layer of the sensor electrode. It should be pointed out that the S-TouchTM touch controller is arranged at the bottom layer, and it should be ensured that no sensor electrode is arranged at the corresponding top layer. The blank area of the top and bottom layers can be filled with mesh grounding copper foil.

Design rules

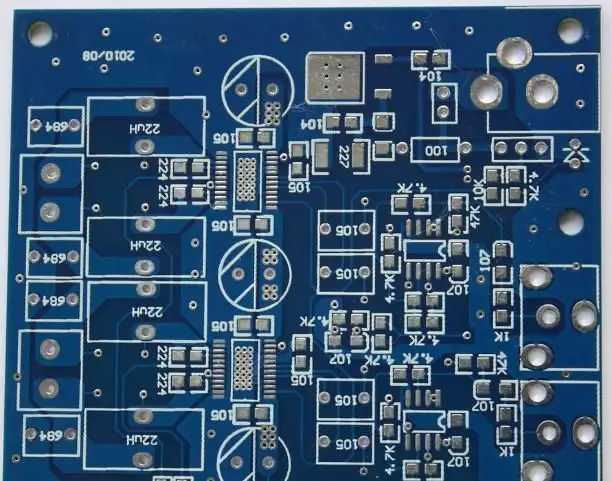

1st floor (top floor)

● The sensor electrode is located on the top layer of the PCB (the upper end of the PCB is fixed with the clad plate). To improve sensitivity, it is recommended to use an inductive electrode with a size of 10 x 10mm. A smaller size of sensing electrode can be used, but the sensitivity will be reduced. It is also recommended that the size of the sensing electrode should not exceed 15 x 15 mm. If the sensing electrode exceeds this size, it will not only reduce the sensitivity, but also increase the susceptibility to noise.

● The blank area can be filled with grounding copper foil (trace width is 6 mils, grid size is 30 mils).

● The top layer can be used to lay common signal traces (excluding sensor signal traces). The sensor signal trace should be laid on the bottom layer as much as possible.

● The distance between the induction electrode and the grounding copper foil shall be at least 0.75 mm.

2nd floor (ground floor)

● The S-TouchTM controller and other passive components shall be designed and arranged at the bottom.

● The sensor signal trace will be laid on the bottom layer. Do not lay the sensor signal trace of one channel below the sensing electrode of other sensing channels.

● The blank area can be filled with grounding copper foil (trace width is 6 mils, grid size is 30 mils).

● The distance between the sensor signal trace and the grounding copper foil shall be at least twice the width of the sensor signal trace.

● In order to reduce crosstalk, the distance between two sensing electrodes/sensing signal traces should be increased as much as possible. If possible, add grounding copper foil between two sensing electrodes/sensing signal traces.

● The length of the sensor signal trace does not need to be completely equal. Because the matching tuning capacitor is used, the input capacitance between the two channels can be balanced completely. However, if PCB space allows, it is better to use sensor signal traces with equal length (the dimensions of sensor electrodes are also uniform). In this way, in order to adjust the sensor reactance values of all sensing channels to the dynamic range induced by the controller, it is only necessary to set a standard reference capacitor, which simplifies the design difficulty.

● Any trace of clock, data or periodic signal shall not be laid in parallel adjacent to the signal trace of the sensor. These signal lines should be perpendicular to the signal trace of the sensor as much as possible, or laid in other areas of the PCB.

● If the trace of clock, data or any periodic signal really needs to be laid in parallel with the signal trace of the sensor, they should be laid on different layers without overlapping, and the length of the parallel part of the signal trace should be shortened as much as possible.

Grounding copper foil

In the previous introduction of two layers of FR4 PCB, the grounding copper foil is used to fill the blank section area of PCB. Grounding copper foil can help shield the touch module from external noise sources and stabilize the inherent capacitance of the sensor circuit.

However, when using grounding copper foil, several problems should be paid attention to in advance. This is because grounding copper foil will increase the inherent capacitance of the sensor, and also increase the possibility of false detection due to water droplets.

Grounding copper foil design guide:

● It is recommended to use mesh grounding copper foil instead of solid grounding copper foil. It is recommended to use 20% mesh grounding copper foil (trace width is 6 mils, grid size is 30 mils). The angle of the grounding copper foil should be set at 45 °.

● The distance between the sensor and the grounding copper foil should be at least 0.5 mm, and 0.75 mm is recommended.

● The gap between the sensor signal trace and the grounding copper foil should be at least twice the trace width.

● For a four layer PCB, if the sensor signal trace laid on the third layer is greater than 10 cm, it is recommended not to lay grounding copper foil on the bottom layer to minimize the capacitive load of the long trace.

● If some conductive materials are used for the clad plate, it is recommended not to lay grounding copper foil on the top layer.

● If the capacitive induction system needs to work in a humid environment, it is recommended not to lay grounding copper foil on the top.

Basic function description and guide of sensor

Capacitance sensor electrode refers to a conductive electrode plate used to measure finger capacitance. It is connected to the input of the sensing channel of the S-TouchTM controller. Sensor electrodes can be fabricated into various geometric shapes and sizes for different functions and applications.

Touch key

The basic function of the touch button is to detect whether a finger is touching. The S-TouchTM controller can measure the capacitance of the touch key sensing electrode. If the finger is close to the touch button, when the measured capacitance changes beyond the preset threshold, the finger touch will be detected.

The touch keys can be designed into various shapes, such as square, circle, triangle or other shapes. If the size of PCB is limited, the designed button shape should maximize the use of space to provide the best sensitivity.

For applications covered with 2-3 mm acrylic plastic shell, a square sensing electrode with a minimum size of 10 x 10 mm is recommended. It is recommended that the maximum size does not exceed 15 x 15 mm. If the size is exceeded, not only the sensitivity cannot be improved, but also the noise susceptibility will be increased.

Touch slider

The basic function of the touch slider is to detect the sliding position of the finger in the one-dimensional direction.

One of the typical applications of touch slider is volume control. Two methods can be used to implement the touch slider: the touch status slider and the proportion metering slider.

The square touch buttons can be arranged closely in order to design a touch status slider.

When it is detected that a sensing channel is open, the position of the finger on the touch slider can be determined. In the above example, 5 sensors are used to detect 9 positions. If both S1 and S2 channels are turned on at the same time, it means that the finger position is at position 2.

For applications covered with 2-3 mm acrylic plastic shell, it is recommended to use a sensing electrode with a minimum size of 10 x 10 mm. The recommended clearance between the sliding strip sensors is 0.75 mm. The gap between two adjacent sensing electrodes should not exceed 1mm. This is to ensure that both sensor channels can be opened simultaneously when the fingers are just in the gap.

The advantages of touch state slider are simple design and high stability in noisy environment. However, if a large number of locations are required, this method cannot be implemented because too many sensor channels are required.

Another method is to use the proportional metering slider. This method is not realized by detecting the touch state on each sensor channel, but by determining the finger position according to the exact capacitance change measured by each sensor channel. After the exact capacitance change of each sensing channel is measured, the exact position of the finger can be determined through the proportion calculation.

Finger touch in the above positions will increase the capacitance of the three sensing channel electrodes. Due to different finger coverage areas, the added capacitance of each sensor is different. Then, the absolute position of the finger on the slider can be obtained by processing the original capacitance data of the sensor.

Touch spinner

Like the slider, the touch rotator is also based on the touch state and the proportional measurement method.

The rotator using the touch state method determines the position of the finger by checking the state of each sensing channel. The rotator of proportional measurement method is used to determine the position of fingers by measuring the exact capacitance of each sensing channel increased due to finger touch. When the finger rolls on the rotator, the capacitance of several sensing channels will increase. Then, by calculating the capacitance value added by these sensing channels, the exact position of the finger touch can be calculated.

The stability of the touch rotator for finger touch detection depends on the required resolution and the number of sensing channels. For high-resolution touch rotators, more sensing channels may be required, rather than only three sensing channels.

Other considerations

PCB design and layout according to these basic design guidelines can make capacitive induction applications more reliable. In PCB design, other important factors should be considered, including:

● There is no float/pole plate on PCB. The blank area of PCB can be filled with grounding copper foil or left blank.

● PCB board shall be designed to require a reference capacitance value less than 20 pF (the reference capacitance value is determined during hardware adjustment), and the inherent capacitance of each channel shall be less than 10 pF. If it is greater than this value, it is necessary to modify some basic layouts, such as reducing the density of the grounding copper foil, expanding the distance between the inductive input trace/electrode and the grounding copper foil, narrowing the width of the sensor signal trace, or even removing the grounding copper foil. If the maximum value of the inductive input capacitance exceeds 10 pF, the tuning capacitance is required for matching settings.

● Try to control the difference of inherent capacitance between each induction channel within 10 pF (this difference can be measured during hardware adjustment). If it exceeds 10 pF, it is necessary to reduce the mismatch between the trace length and the sensor electrode size to carry out a re layout to minimize the difference.

● Install a series resistor in the I2C SDA and SCL lines to filter the noise interference caused by the harness connecting the mainboard and the touch module, or the interference from the power supply noise that may cause distortion of the I2C signal.The purpose of this application guide is to provide design layout guidance for the structure and layout of various PCBs used in S-TouchTM capacitive touch sensing design.