The benefits of portable intelligent driver for PCB layout

One win: intelligent drive transfers processor tasks

The solution based on the ADP5520 intelligent backlight driver can obtain significant energy saving from the LED driver, which can work under the configuration control of the microcontroller, or automatically manage the display lighting. The ADP5520 consists of an asynchronous boost converter, a programmable environment light management PCB circuit, a state machine, and a configurable port extender that can further save system resources.

The boost converter can supply power to up to six white LEDs in series, with a series voltage of up to 24.5V and a drive current of up to 30mA. The ambient light measurement part provides all signal conditioning functions for the ambient light sensor, and together with the on-chip state machine and boost converter, 128 current levels of 0~30mA are achieved.

Since a processor only performs light control services similar to the control curve, ADP5520 can prolong the working time of each charge by 15% in the test of simulating the usage rate of various mobile phones. Adding the environmental light detection function to the ADP5520 control method can make the standby time of each charge 50% more than the reference measurement value. These curves simulate mobile interactive applications that do not require RF functionality, such as games, text and email message reading and writing or camera applications.

Designers want their products to smoothly transition between different light levels, not just switch. The lighting scheme under processor control requires a lot of processor interaction to achieve smooth transition. Therefore, compared with simple switch control, this scheme greatly increases the load of the processor. Intelligent LED drivers, such as the ADP5520, can achieve a variety of dimming and brightening current changes, including linear, square and cubic laws, thus further reducing the processor load (Figure 2). This configurable driver has 15 discontinuous and independent fader times, ranging from 300ms to 5.5s. There is a resettable dimming timer on the chip, which can be programmed as one of 15 time intervals from 10s to 120s.

Win win: Smart drives provide additional low bandwidth capabilities

In addition to energy conservation, this intelligent drive can provide more value by realizing other low bandwidth peripheral functions. For example, the ADP5520 integrates a configurable port extender that provides eight I/O pins.

Two I/O pins can also be connected to the third dedicated pin as independent current sink pins for LED indicators with programmable dimming, switching, and flicker control functions. The remaining pins are programmable for keyboard or general I/O.

These auxiliary LED drivers can consume 0~14mA current, and can be gradually lightened or darkened through 64 steps. As with the current consumption of the main backlight, the indicator connected to the auxiliary driver pin can switch the switch status or adjust the light through linear or nonlinear sequence.

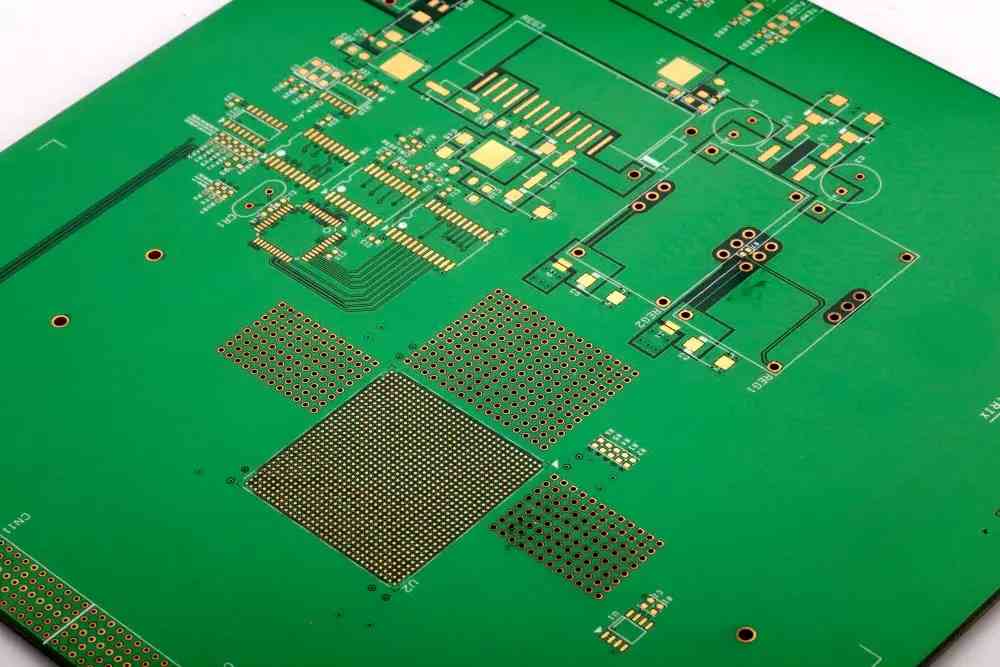

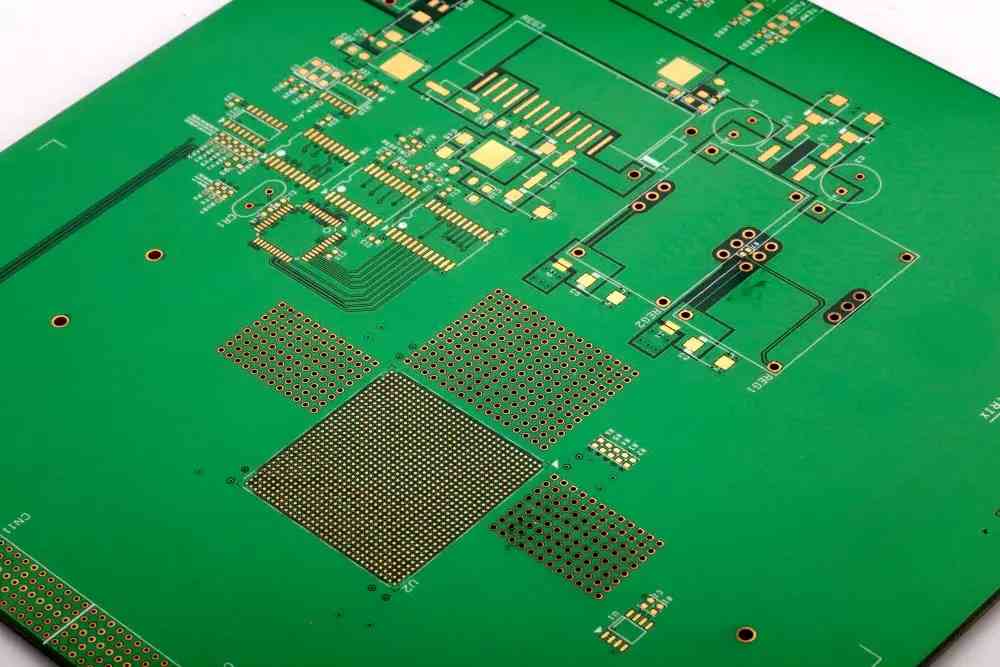

Win win: intelligent drive can reduce the number of PCB wiring

In order to let the configuration data flow from the processor to the intelligent drive and let the status, I/O or keystroke data flow back to the processor, the ADP5520 implements the I2C interface. This setting can reduce the number of devices and wiring between peripherals and controllers, thus simplifying the PCB (printed PCB circuit board) design in high-density portable electronic devices.

When a hinge or slider mechanism is used to separate the display, indicator, and keyboard from the processor, the energy-saving effect will be more significant. In this case, an intelligent LED driver with an on-chip port expander can reduce the size and cost of a flexible PCB connected to the other half of the product. The circuit board assembly and circuit board processing manufacturers explained that the portable intelligent driver makes PCB layout more orderly and win-win.