Thermal conductivity and heat dissipation performance parameter of aluminum substrate, which is one of the three standards to measure the quality of aluminum substrate. The radiator design process is mainly divided into three steps: 1. According to the relevant constraints to design the outline of the radiator;

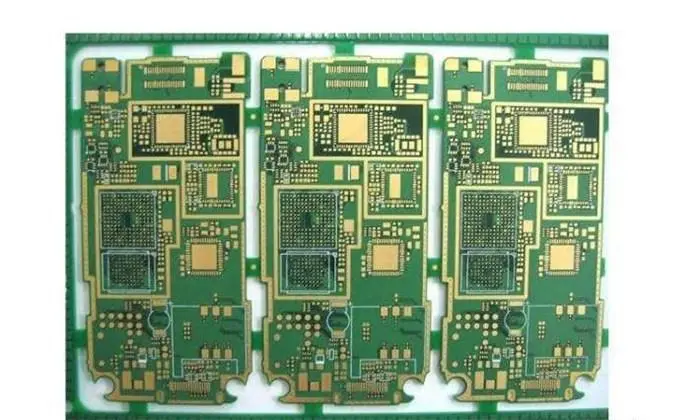

As the name implies, the thermal conductivity of aluminum substrate is a thermal performance parameter of aluminum substrate, which is one of the three standards to measure the quality of aluminum substrate (thermal resistance value and withstand voltage value are the other two properties). The thermal conductivity of aluminum substrate can be measured by a testing instrument after the plates are pressed together. At present, ceramics and copper have high thermal conductivity values. However, considering the cost, most aluminum substrates are currently on the market. The corresponding thermal conductivity of aluminum substrate is a parameter concerned by many people. The higher the thermal conductivity is, the better the performance is. Aluminum substrate is a unique metal based copper clad aluminum substrate, which has good thermal conductivity, electrical insulation and mechanical processing properties.

In general, aluminum substrate will be used in LED design and various circuit board design, and LED heat dissipation design is simulated and designed based on fluid dynamics software, which is very necessary for the production of aluminum substrate.

The so-called resistance of fluid flow is due to the influence of the viscosity of the fluid and the solid boundary, which causes the fluid to suffer a certain resistance in the flow process. This resistance is called flow resistance, which can be divided into two types: along path resistance and local resistance; Along the way resistance refers to the flow resistance caused by the sharp change of fluid flow state in the area with sharp changes in the boundary, such as the sudden expansion or contraction of the section, elbow and other local locations

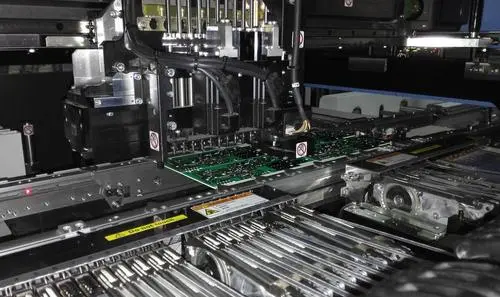

Generally, the heat sink used for LED aluminum substrate is natural heat dissipation, and the PCB design process of the heat sink is mainly divided into three steps:

1. According to the relevant constraints to design the outline of the radiator;

2. The tooth thickness, tooth shape, tooth spacing and the thickness of aluminum substrate are optimized according to the relevant design criteria of aluminum substrate radiator;

3. Check and calculate to ensure the heat dissipation performance of the radiator.