Sharing of wiring topology of power, data and peripherals in PCB

The more advanced digital interfaces between PCB boards and boards in larger systems draw on standard network topologies. Although the appearance factors may have changed over the years, the electrical connection structure between components and subsystems in electronic products has not changed at all.

If you are a new designer who has just started to use advanced interfaces such as DDR, or you are wiring your first bus protocol, it is important to know some basic knowledge about PCB wiring topology. There is also the problem of designing power distribution. It can have its own power bus routing protocol, connections between circuit boards, and ensure that the grounding in the system is consistent.

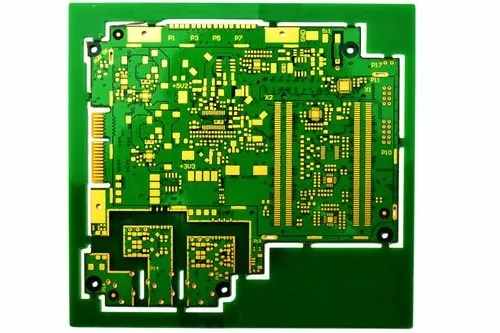

Common wiring topology in PCB

Several common routing topologies are used in the entire PCB to route power, digital data, and even some special analog systems. Some advanced topologies are used for computer peripherals, such as memory. Common routing topologies in PCBs have the same name as their network topology analogues, so it is helpful to be familiar with these areas. Different from the network, the goal of routing topology configuration in PCB design is not limited to data transmission between components. The power supply is also "routed" around the system in a determined topology, and different topologies may be selected for various reasons.

Some of these standard topologies may be used as layout and routing topologies in your PCB.

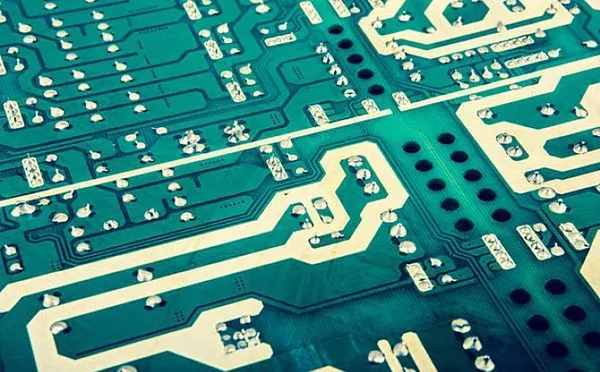

When we narrow down to a higher level of abstraction, we begin to see how these topologies begin to resemble standard network topologies. At the fine-grained level, we look at individual components. Only some of these topologies are practical at the board level.

Some comments are useful here because they show where each topology can be useful and how they can actually be used in different parts of the system.

Star wiring can be used to provide multiple ground connections for a single distribution point. The star topology is also used with the system clock in the high-speed PCB board. The signal originates from a single point and is routed to different components on the board as needed. Note that the terms "source single point" and "star" are two different names for the same topology. The difference from star topology is that the source point is located at the center of the downstream component.

Tree routing (or multipoint) applies to the same idea of multiple "stars" in the hierarchy, where multiple power rails are disconnected from a single point and sent to different circuit blocks or devices. Another variant is the source multipoint topology, where a single power rail is used as a bus and supplies power to the downstream circuit blocks.

Routing topology of memory and computer peripherals

When it comes to memory modules and their interfaces with processors, more complex topology combinations will connect the devices in the board. Simple point-to-point topology is also used for advanced protocols such as PCIe. Let's look at these examples, because they illustrate how standard routing topologies adapt to advanced signaling standards.

T-topology

T topology is used for DDR2 and less advanced DDR3 versions. This is a combination of tree and point-to-point network routing topology. Command, clock, and address tracking are routed in a tree network, while data lines are routed point-to-point directly to the processor. Although this topology is useful for taking advantage of higher data rates, the number of available memory modules and the data transfer rate are limited by capacitive loads.

Flyover topology

Newer DDR memory modules use the fly over topology. The main topologies used in DD3 and DDR4 represent a combination of point-to-point networks and bus networks. Power/ground, command, clock, and address signals are routed through the bus to each DRAM/SDRAM and then to the processor using differential pairs. This is a major upgrade compared to DDR2 and earlier memory. Compared with the T topology, the flyover topology supports running at a higher data rate, while reducing the timing deviation between the overloaded signals transmitted from the processor to the memory module. PCB assembly and PCB processing manufacturers explain the sharing of power, data and peripheral wiring topology in PCB.