The circuit board processing factory explained that surface mounting technology is a part of PCB design. Surface mounting technology process integrates surface mounting technology into PCB design.

PCB layout rules:

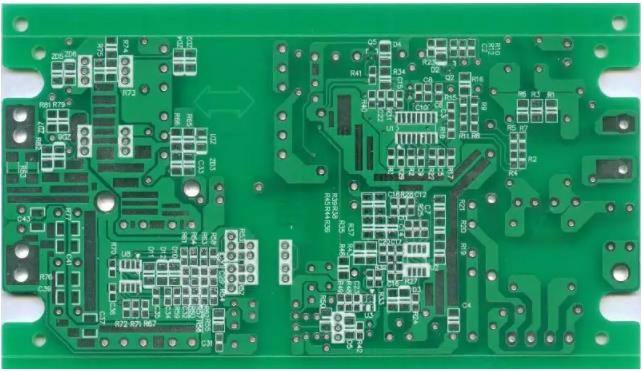

1. In general, all components should be arranged on the same side of the circuit board. Only when the top layer components are too dense can some devices with limited height and low heat generation, such as chip resistance, chip capacitance, chip IC, etc., be placed on the bottom layer.

2. On the premise of ensuring the electrical performance, the elements shall be placed on the grid and arranged in parallel or vertical to each other for neat and beautiful appearance. In general, the elements are not allowed to overlap; The elements shall be arranged compactly, and the elements shall be evenly distributed and uniformly spaced throughout the layout.

3. The minimum spacing between adjacent pad patterns of different components on the circuit board shall be more than 1MM.

4. The distance from the edge of the circuit board is generally not less than 2 mm. The best shape of the circuit board is rectangular, with a length to width ratio of 3:2 or 4:3. When the size of the circuit board is greater than 200 mm by 150 mm, the mechanical strength that the circuit board can withstand should be considered.

Surface mount technology or SMT is a process used by major manufacturers and designers of printed circuit boards or PCBs. They appear in almost any electronic equipment and are technologies that bring great advantages and many benefits. Is it beyond the capacity of general manufacturers? Not in the design process, and when you can integrate surface mount technology into PCB design, you will enjoy the following advantages:

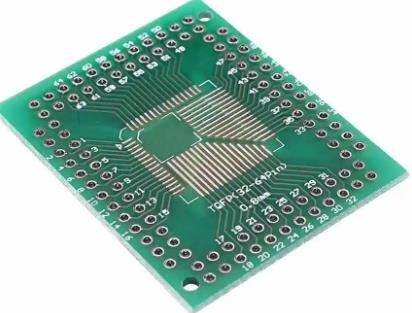

The device has more functions – surface mount technology can reduce the total weight of almost all PCBs. However, in terms of labor, the requirements for producing them are not high, because it largely eliminates the trouble of drilling and welding. This means lighter, smaller PCBs and lower risk of failure.

Compact and powerful – SMT means smaller devices with better performance and lower cost.

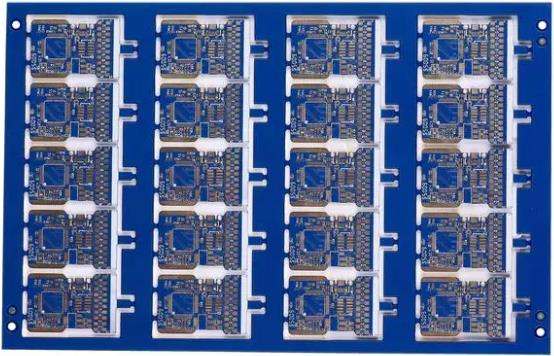

Automation – The use of surface mount technology allows any manufacturer to take advantage of the advantages of mass production of PCBs to produce higher quality and better performance PCBs.

Lower cost and shorter production time – By eliminating several standard production steps, it makes surface mount technology faster and cheaper.

Can all PCB manufacturers provide surface mount technology? Unfortunately, no, it is very important for any equipment manufacturer or designer to spend time looking for options in integrating SMT into their design, manufacturing and assembly processes.

Make full use of SMT and advanced circuit resources

For those who are eager to use SMT tools and resources in their PCB design, we have advanced design tools that can easily integrate surface mount technology. It all started with Gerber files. This is the most common and common file type used in PCB production, and whether Gerber files are used usually affects whether the design is untested when it is sent to production.

In fact, this is what is called non-contact production - the manufacturer can obtain documents and produce without any engineering review. Buyers using intermediary or outsourcing systems often encounter this problem and face financial risks due to defective design. The circuit board processing factory explained that surface mounting technology is a part of PCB design. Surface mounting technology process integrates surface mounting technology into PCB design.