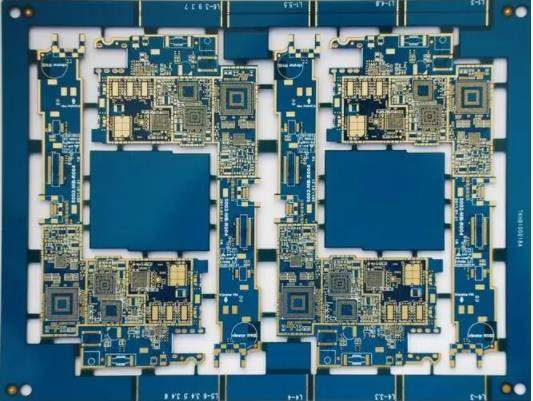

There are many pcb boards in contact, but some common sense is rarely used in practice, which may not be understood. For example, high tg, reverse copper foil substrate, what is RCC and its use, let's briefly understand.

First of all, some people will wonder why PCB manufacturers use high Tg materials when producing PCB? Our circuit board manufacturers have a lot of professional knowledge in the production of circuit boards. Here's the answer:

First of all, high Tg refers to high heat resistance. With the rapid development of electronic industry, especially the development of PCB products represented by computers towards high functionality and high multilayer, higher heat resistance of PCB substrate materials is required as an important guarantee. With the emergence and development of high-density installation technology represented by SMT and CMT, PCB production in our circuit board factory is increasingly dependent on the support of high heat resistance of the substrate in terms of small aperture, fine wiring and thinness.

PCB substrate materials not only produce softening, deformation, melting and other phenomena at high temperatures, but also show a sharp decline in mechanical and electrical properties (I don't think you want to see this happen to your products). Therefore, the difference between the general FR-4 and the high Tg FR-4 is that in the hot state, especially in the heat after moisture absorption, the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the materials are different. The high Tg products are obviously better than the ordinary PCB substrate materials.

What is reverse copper foil substrate

The traditional electroplating copper sheet has two parts: the smooth surface and the roughened surface. Generally, the roughened copper surface is connected with the resin in the use of the circuit board, so as to generate tension and make the resin and copper foil have a strong bonding force. However, because the coarsened surface is deep, if the roughened surface is used on the surface of the circuit board, the uniform rough surface can be directly attached to the dry film in the future, and good bonding force can be achieved without too much pretreatment, Therefore, the copper sheet supplier tries to reverse the rough surface of the copper sheet and strengthen and combine the smooth surface. This is the so-called reverse copper sheet. Because the roughness of the smooth surface is very low, it is easier to etch clean when making thin lines, which is beneficial to the production and improvement rate of thin lines in circuit board factories. Therefore, some circuit board manufacturers have started to do this application.

What is RCC and its purpose

RCC is Resin Coated Copper, which is called "resin coated copper sheet" or "resin coated copper sheet" in Chinese translation. It is mainly used for the manufacturing of HDI Board High Density Interconnection Board. Circuit board manufacturers can increase the manufacturing capacity of high-density small holes and thin wires during production. Because the small hole production includes not only the pressing hole work, but also the electroplating work of the blind hole. Because blind hole electroplating is basically different from through hole electroplating, it is difficult to replace the solution, so the thickness of dielectric material should be reduced as much as possible. For the requirements of these two production features, RCC can provide these production features, so it is adopted.

Especially in the early stage of the development of high-density circuit boards, because the laser technology is not developed and the processing speed is slow, for traditional circuit board materials, it is really difficult to use in practice, so RCC came into being as the times require and became an important material.