As the RF circuit is a distributed parameter circuit, it is easy to produce skin effect and coupling effect in the actual work of the circuit, so in the actual PCB design, it is difficult to find the interference radiation in the circuit control.

For example, interference between digital circuit and analog circuit, noise interference of power supply, unreasonable ground interference and other problems.

Because of this, how to balance the pros and cons and seek a suitable compromise in the process of PCB design, as far as possible to reduce these interference, or even avoid the interference of part of the circuit, is the key to the success or failure of RF circuit PCB design.

In this paper, some processing techniques are provided from the perspective of PCB LAYOUT, which is of great use to improve the anti-jamming ability of RF circuit.

One,RF layout

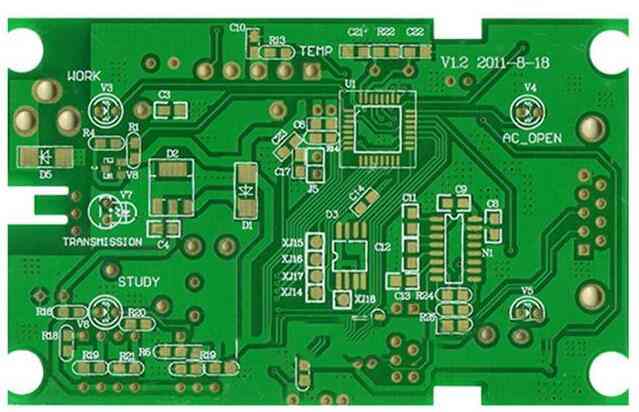

The main discussion here is the multilayer board component location layout.

The key to the location layout of components is to fix the components located on the RF path. By adjusting their direction, the length of the RF path is minimized, and the input is far away from the output. High power circuit and low power circuit are separated as far as possible, and sensitive analog signals are far away from high-speed digital signals and RF signals.

The following techniques are often used in the layout:

1. A zigzag layout

RF main signal components as far as possible using a font layout.

However, due to the limitations of PCB board and cavity space, many times can not be cloth into a glyph, this time can use L shape, it is best not to use U-shape layout, sometimes it is unavoidable, as far as possible to expand the distance between the input and output, at least 1.5cm above.

In addition, when using L shape or U shape layout, the turning point is best not to turn just into the interface, but to turn after a slightly straight line.

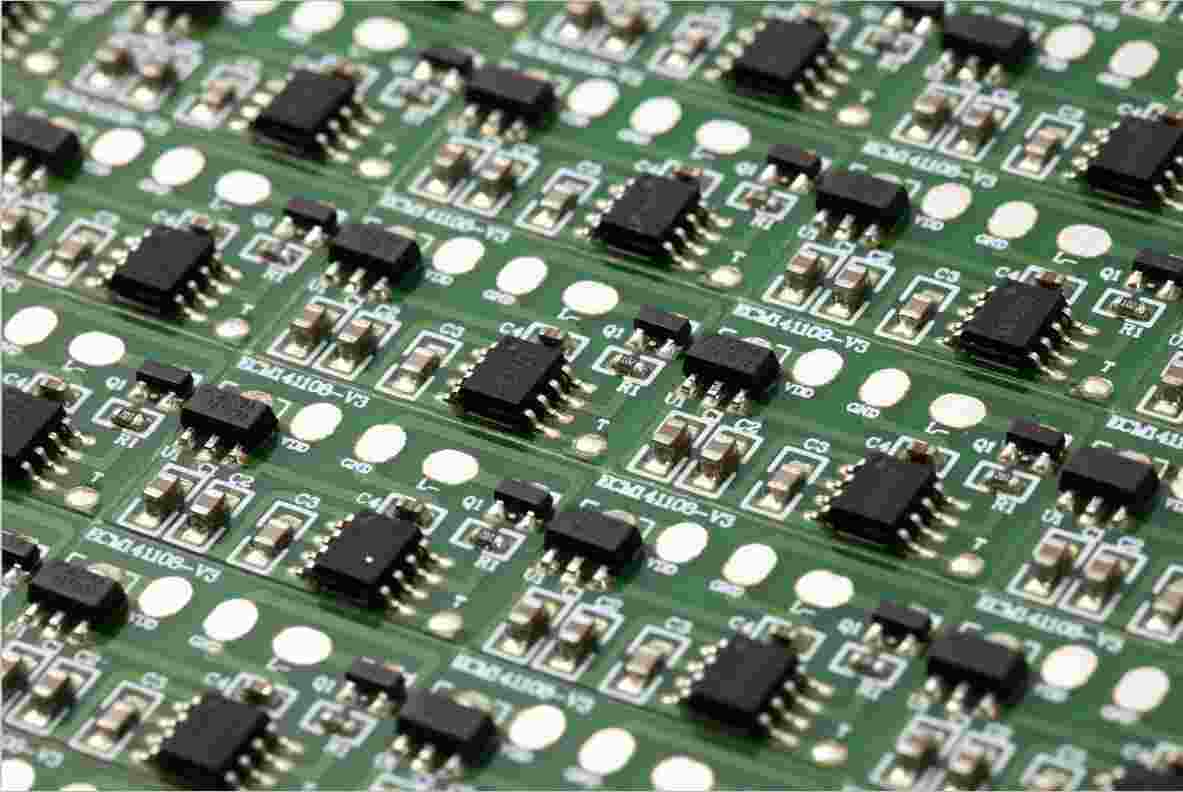

2, the same or symmetrical layout

The same modules should be in the same layout or symmetrical layout as possible

3. Cross layout

The feed inductance of the bias circuit is placed vertically with the RF channel, mainly to avoid mutual inductance between inductive devices.

4,45 degree layout

In order to make proper use of space, the device can be arranged in a 45 degree direction to make the RF lines as short as possible.

Two, RF wiring

The general requirements of wiring are: RF signal line short and straight, reduce the mutation of the line, less hole, not intersecting with other signal lines, RF signal line perimeter as much as possible through the hole.

Here are some common optimizations:

1, gradient line processing

When the RF linewidth is much larger than the pin width of the IC device, the linewidth of the contact chip adopts a gradual change.

2, arc line processing

If the RF line is not straight, arc line processing can reduce RF signal external radiation and mutual coupling. It has been proved by experiments that the corner of the transmission line is curved at a right Angle, which can minimize the return loss.

3. Ground wire and power supply

The ground wire is as thick as possible. Under conditions, each layer of PCB circuit board should be paved as far as possible, and the ground should be connected to the main ground, and more holes should be drilled to reduce the ground impedance as far as possible.

The power supply of RF circuit should not be segmented by plane as far as possible. The whole power plane not only increases the radiation of the power plane to RF signal, but also is easy to be interfered by RF signal. Therefore, the power line or plane generally adopts the shape of a long strip, which is processed according to the size of the current. It is as thick as possible under the premise of meeting the current capacity, but it cannot be widened without limit. When handling power cables, be sure to avoid loops.

The direction of the power cable and ground cable should be parallel to the direction of the RF signal but should not overlap. It is best to use a vertical cross where there is a cross.

4. Cross processing

Cross the RF signal with the IF signal, and try to put a space between them.

When RF signals are crossed with other signals, try to arrange a layer of ground connected to the main ground along the RF lines between them. If that's not possible, make sure they're crossed. Other signal wiring here includes power cables.

5, cover the ground processing

Rf signals, interference sources, sensitive signals and other important signals for packet processing, so that not only can improve the anti-interference ability of the signal, but also can reduce the signal interference to other signals.

6, copper foil treatment

Copper foil processing requirements are smooth and smooth, do not allow long lines or sharp corners, if can not avoid, in sharp corners, slender copper foil or copper foil edge to fill several holes.

7. Spacing processing

The RF cable must be at least 3W wide from the edge of the adjacent ground plane, and no ungrounded holes are allowed within 3W.

The radio frequency line of the same layer should be covered with ground processing, and add ground holes on the copper skin, hole spacing should be less than the signal frequency of the corresponding wavelength (λ) of 1/20, uniform arrangement. The edge of the copper cladding is 2W wide or 3H high from the RF line, where H represents the total thickness of the adjacent dielectric layer.

Three, cavity treatment

For the whole RF circuit, the RF units of different modules should be isolated with cavities, especially between sensitive circuits and intense radiation sources. In high-power multistage amplifiers, the isolation between stages should also be ensured.

After the entire circuit tributary is placed, it is the processing of the shielding chamber. The processing of the shielding chamber has the following precautions:

The whole shielded cavity should be shaped as regularly as possible to facilitate casting. For each shielding cavity as far as possible to make rectangular, avoid square shielding cavity.

The corner of the shielding cavity is arc, and the shielding metal cavity is generally cast, and the corner of the arc is easy to draw the mold when casting.

The perimeter of the shielded cavity is sealed, and the interface lines are generally introduced into the cavity by strip lines or microstrip lines, while the different modules inside the cavity adopt microstrip lines, and the connecting parts of different cavities are treated by grooves. The width of the grooves is 3mm, and the microstrip lines walk in the middle.

A 3mm metallized hole is placed at the corner of the cavity to fix the shield shell. Equal metallized holes should also be placed evenly on each long cavity to reinforce the supporting effect.

The cavity is generally windowed to facilitate welding of the shield shell. The thickness of the cavity is generally more than 2 mm, and 2 rows of Windows are added to the cavity. The holes are staggered to each other, and the spacing between the same row of holes is 150MIL.

Four, concluding remarks

The key to the success or failure of RF circuit PCB design is how to reduce the circuit radiation, so as to improve the anti-interference ability, but in the actual layout and routing of some problems are in conflict with each other, so how to find a compromise point, so that the overall performance of the whole RF circuit to achieve the best, is the designer must consider the problem.

All these require designers to have certain practical experience and engineering design ability, but to have these abilities, every designer can not be accomplished in one move, only learn from the experience of others, coupled with their own constant exploration and thinking, in order to continue to progress.