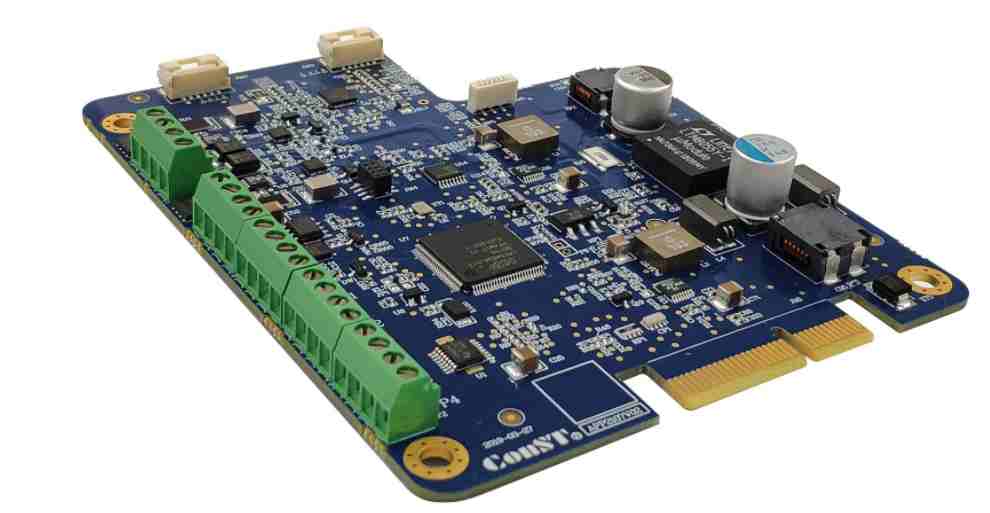

Some special custom material selection and process requirements price will increase or decrease accordingly, these are to be cost accounting. So, circuit board costs should be how to calculate? = Materials + labor + manufacturing costs. What materials are included? PCB process is long, in the production cost of this link, there is a lot of room to control. Production costs include: raw material control, water and electricity control, scrap rate control, process control, etc. The following will explain how to calculate the cost of the circuit board and how to avoid crosstalk in PCB design.

1. How does PCB design avoid crosstalk

The signal of PCB design change (such as step signal) is propagated along the transmission line from A to B, and the coupled signal will be generated on the transmission line C-D. Once the signal of PCB design change is over, that is, the signal returns to stable DC level, the coupled signal will not exist. Therefore, crosstalk only occurs in the process of signal jump, and the faster the signal change (conversion rate) along the transmission line, The more crosstalk you have. The coupled electromagnetic field in space can be extracted as a collection of coupling capacitors and coupling inductors. The crosstalk signal generated by coupling capacitors can be divided into forward crosstalk and reverse crosstalk Sc on the victimized network, and the two signals have the same polarity. Crosstalk signals generated by coupled inductors are also divided into forward crosstalk and reverse crosstalk SL, which are of opposite polarity.

Forward and reverse crosstalk generated by coupled inductance capacitors exist at the same time and are almost equal in size. In this way, forward crosstalk signals on the victim network cancel each other due to opposite polarity, while reverse crosstalk signals have the same polarity and are enhanced by superposition. The modes of crosstalk analysis usually include default mode, three-state mode and worst case mode analysis. The default mode is similar to how we actually test crosstalk, that is, the offending network driver is driven by a rollover signal, the offending network driver remains in its initial state (high or low), and the crosstalk value is calculated. This method is more effective for crosstalk analysis of one-way signal. The three-state mode means that the offending network driver is driven by a rollover signal, and the three-state terminal of the affected network is set to a high resistance state to detect the crosstalk size.

This method is more effective for bidirectional or complex topology networks. Worst-case analysis means that the driver of the victim network is left in its initial state and the emulator calculates the sum of the crosstalk of all the default offending networks to each victim network. In this way, only a few key networks are analyzed, because there are too many combinations to be calculated, and the simulation speed is slow.

2. How should the cost of the circuit board be calculated

The costing method of circuit board is generally through different processes, different materials processing and other comprehensive factors to calculate the cost, the price is generally calculated by per square meter unit. Of course, some special customized material selection and process requirements price will increase or decrease correspondingly, these are to be accounted for by the cost. So, circuit board costs should be how to calculate? Here is kingford to share with you. Cost = materials + labor + manufacturing expenses Which materials include? PCB process is long, in the production cost of this link, there is a lot of room to control. Production costs include: raw material control, water and electricity control, scrap rate control, process control, etc.

1. Control of raw materials

For the same board, the one who can use the least amount of materials to complete it will have the lowest production cost, and to control the least amount of materials is to control the rework rate and the waste rate of employees. Although many factories have PMC departments to limit the production of materials, these are the measures to treat the symptoms rather than the root cause. It also needs to start with the proficiency of the staff, the management ability of the supervisor and the design of the process. A set of strict management system and reasonable mode of operation, will reduce a lot of human error. Suggest some key positions, select experienced staff to complete. For example: process designer, production supervisor, MI programming engineer, etc!

2. Water and electricity control

The rational use of water and electricity, especially the peak season often lack of power, many places are to take power limiting control, the machine is not used, must be stopped, such as tube, etching pull, drilling/gong machine and other equipment, planned production, reasonable electricity, can reduce the cost of greater. Advocate the production planner, to be skilled in the process, to work closely with the production and marketing departments, often communicate, in order to get timely information, so as to arrange the production plan reasonably!

3. Scrap rate control

Scrap board is indeed a pity, especially in the market copper plate surging, material floating, PCB profit decline, such as scrap rate is too high, the enterprise economy is undoubtedly worse. How to control scrap rate! This requires us to find a better operating system and management system to tolerate the negligence of employees and the instability of materials. In the control of scrap rate of this link, we can control from the following points: (1) Enhance the awareness of employees, let them understand that the circuit board e is a valuable thing and must be handled with care at any time, do not let them feel that what we produce is cheap or garbage board, then naturally he will not treat it as a treasure. For example, when we ask to hold the board, two hands must hold the edge of the board, we do not say that this will bring benefits to the quality. This simple posture can let a person feel the preciousness of this board! (2) QA and MRB (scrap reviewer), who is very important to judge whether the board should be scrapped, must have a high sense of responsibility and be familiar with all the processes. If the board that can be saved is judged as scrapped, it is undoubtedly a waste. If the board that cannot be saved is judged as qualified and continues to the next process, I'll waste the raw materials for the post-process again. (3) Constantly introduce new technology and seek the most reasonable working mode to tolerate employees' mistakes. (4) Let every employee know the monthly scrap rate, so that they feel the benefits of reducing the scrap rate! Often summarize the reasons for scrapping, to know how our board was scrapped. A good PCB board is from the selection of materials and need to be rigorous, careful to do a good job of each process, not careless, material cost and process precision also determines the final offer of the circuit board.