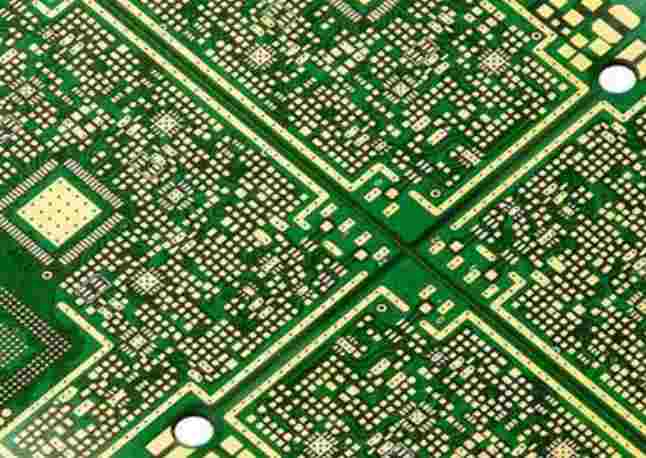

PCB board is the basic material of PCB, often called substrate. Copper Clad Laminate (Copper Clad Laminate, full name copper clad, CCL for short), is made of wood pulp paper or glass fiber cloth as reinforcement material, impregnated resin, single or double clad copper foil. Copper clad plate is the basic material of electronic industry, mainly used in the processing and manufacturing of printed circuit board (PCB), widely used in TV, radio, computer, computer, mobile phone, communication and other electronic products.

According to different classification standards, the classification is as follows

One: according to the mechanical stiffness of copper clad plate is divided into rigid copper clad plate and flexible copper clad plate;

Two: according to the insulation materials and structure of the copper clad plate, it is divided into organic resin copper clad plate, metal copper clad plate, ceramic copper clad plate;

Three: according to the flame retardant grade is divided into flame retardant plate and non-flame retardant plate: according to UL standard (UL94, UL746E, etc.), the flame retardant grade of rigid copper clad plate is divided into four different kinds of resistance combustion grade: UL-94V0; UL-94V1; Class UL-94V2 and Class UL-94HB.

Four: according to the thickness of copper clad plate is divided into thick plate (plate thickness range 0.8~3.2mm (including Cu)), thin plate (plate thickness range is less than 0.78mm (excluding Cu));

Five: copper clad foil plate can be divided into five categories according to the reinforcement material of the plate:

1: paper base; 2: glass fiber cloth base; 3: Composite base (CEM series); 4: laminated multilayer board base; 5: Special material base (ceramic, metal core base, etc.).

Six: according to the resin adhesive used, it can be divided into:

1: Common paper based CCI include phenolic resin (XPc, XxxPC, FR-1, FR-2, etc.);

2: Epoxy resin (FE-3)

3: polyester resin

4: Other special resins (glass fiber cloth, nylon, non-woven fabric as auxiliary materials) :

(1) bismaleimide modified triazine resin (BT)

(2) Polyimide resin (PI)

(3) diphenyl ether resin (PPO)

(4) maleic anhydride imine - styrene resin (MS)

(5) polycyanate resin

(6) polyolefin resin

Seven: Copper clad plates are divided by TG class (Tg is an important item to measure and characterize the heat resistance of some glass fiber cloth copper clad plates (such as FR-4). For high reliability design, designers tend to choose high Tg plate), according to the grade level from bottom to high as follows:

FR-4A1 grade: This grade is mainly used in military, communications, computers, digital circuits, industrial instruments, automotive circuits and other electronic products.

FR-4A2 Grade: This grade is mainly used for common computers, instruments, advanced home appliances and general electronic products. The series copper clad plate is widely used, and the performance index can meet the needs of general industrial electronic products.

FR-4A3 Grade: This grade CCL is a FR-4 product developed and produced specifically for the home appliance industry, computer peripherals and general electronic products such as toys, calculators, game consoles, etc. Its characteristic is that the performance meets the requirements of the premise, the price is very competitive.

FR-4AB Grade: This grade is a unique low grade product. But the performance indicators can still meet the needs of ordinary household appliances, computers and general electronic products, its price is the most competitive, cost-effective is also quite good.

FR-4B grade: This grade plate is inferior plate, poor quality stability. Not applicable to large area circuit board products. Generally applicable to the size of 100mmX200mm products. It is the cheapest, but customers should choose to use it carefully.

Cim-3 Series: This product is available in three base colors, namely white, black and natural. Mainly used in computer, LED industry, watches, general household appliances and general electronic products (such as VCD, DVD, toys, game consoles, etc.). Its main feature is good blanking performance, suitable for large PCB products that need blanking process molding. This series of products have A1, A2, A3 three quality grades, available for different requirements of customers.

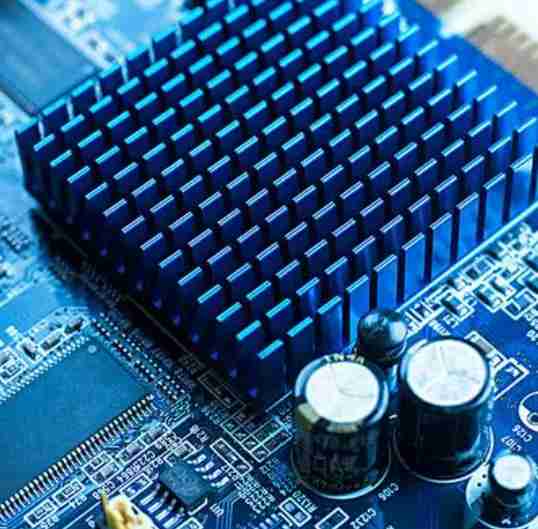

For beginners, learning to judge the quality of PCB board is a must master skill. So, what are the ways to judge the quality of PCB board?

PCB quality judgment method

1. The size and thickness of PCB must be consistent with the specified external size and thickness without deviation. Circuit board surface no defects, deformation, peeling, scratches, open circuit, short circuit, oxidized white, yellow, unclean or excessive etching traces, no dirt, copper particles and other impurities.

2, ink cover uniform, bright, no shedding, scratches, copper exposure, deviation, plate and other phenomena.

3. Clear symbols and letters in screen printing, no omissions, inversions, deviations and other undesirable phenomena.

4, carbon film shall not have defects, deviation, short circuit, open circuit, reverse printing phenomenon.

5, PCB bottom plate molding, no leakage, deviation, hole collapse, tip, plug hole, beer, beer reverse, crush and other phenomena.

6. Whether the PCB edge is smooth, if it is V-shaped cutting process, pay attention to whether the V-shaped cutting groove causes line break, whether the two sides are symmetrical, etc.

A high-quality circuit board must meet the following requirements

1, the requirements of the components after installation to be good, that is, electrical connection to meet the requirements;

2, line width, line thickness, line distance meet the requirements, avoid line heating, open circuit, short circuit;

3. Copper skin is not easy to fall off at high temperature;

4, copper surface is not easy to oxidize, affect the device running speed, oxidation will soon be broken;

5. No additional electromagnetic radiation;

6. No deformation in shape, avoid deformation of shell and dislocation of screw hole after the device. Now are mechanized devices, circuit board hole position and circuit and plane deformation error should be allowed within the range;

7. Tolerance to high temperature, high humidity and special environment is also considered;

8, the surface mechanical properties should meet the requirements of the equipment;