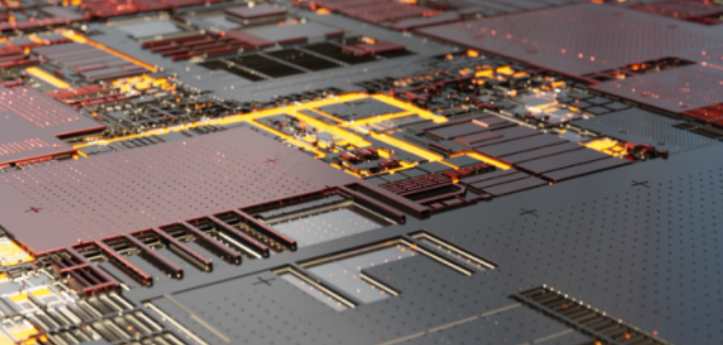

Halogen-free circuit boardis used by the substrate is processed with halogen-free raw materials

halogen-free

Many customers will require the production of halogen-free board, halogen-free board is an environmentally friendly material, halogen-free circuit board is used by the substrate is processed with halogen-free raw materials.

Electronic devices contain certain materials that contain the highest concentrations of halogens. In order to create halogen-free circuit boards in printed boards for electronic devices, certain materials need to be replaced or their use reduced on the boards. You also need to determine the amount of halogen-free elements in the circuit. Some alternative substances require special design considerations and ultimately these considerations will need to be taken into account.

At present, the vast majority of halogen-free plates are mainly phosphorus and phosphorus nitrogen series. When the phosphorous resin is burned, it is decomposed by heat to generate metaphosphoric acid, which has strong dehydrability, forming carbonized film on the surface of the polymer resin, isolating the surface of the resin burning and air contact, so that the fire extinguishes to achieve flame retardant effect. Polymer resin containing phosphorus and nitrogen compounds, combustion produces non-combustible gas, to assist the resin system flame retardant. So, what are the characteristics of halogen-free plates?

1. Insulation of materials

The use of P or N to replace the halogen atom reduces the polarity of the molecular bond segment of epoxy resin to a certain extent, thus improving the insulation resistance and penetration resistance.

02 Water absorption of materials

Express action

As N and P in nitrogen and phosphorus REDOX resin have fewer electrons than halogen, the probability of hydrogen bond formation with water hydrogen is lower than that of halogen materials, so the water absorption of halogen materials is lower than that of conventional halogen flame-retardant materials. For the plate, low water absorption to improve the reliability and stability of the material has a certain impact.

03 Thermal stability of materials

The content of nitrogen and phosphorus in halogen-free plates is higher than that of halogen-based materials, so the molecular weight and Tg value of the monomer are increased. Under the condition of heat, its molecular mobility will be lower than conventional epoxy resin, so the halogen-free material has a relatively small coefficient of thermal expansion.

Halogen-free demand is increasing

Compared with halogen-free plate, halogen-free plate has more advantages, and halogen-free plate replaces halogen-free plate is also the general trend. At present, there are many kinds of halogen-free solder ink on the market. Its performance is not much different from that of ordinary liquid sensitive ink, and the specific operation is basically similar to ordinary ink.

Halogen-free circuit board usually has good heat dissipation reliability and is more suitable for the high temperature process required by lead-free circuit. Also because of its low dielectric constant, can maintain the integrity of the signal. Therefore, the demand for halogen-free circuit boards has been increasing.

04. Understanding of halogen and lead free and restricted use and prohibited use

The restriction of ROHS directive is to prohibit the use of six harmful substances, which requires a correct understanding of the meaning of the directive.

① Do not use:

To prohibit the intentional use of a particular chemical substance, allowing its presence in impurity form but limiting its use as impurity concentration.

2.1 Lead limit value < 100ppm is lead-free

2.2 Cadmium limit < 5ppm

2.3 Mercury limit 1000ppm

2.4 Chrome limit 1000ppm

2.5 PDD /? BDE limit value 1000ppm

2.6 Halogen-free chlorine (C1) (Br) content is less than 0.09% (wt).

2.7 Description of the limit value

In November 1999, JPGA announced the implementation of six halogen-free copper cladding standards, which is the world's first halogen-free copper cladding standards. In this series of standards, the "halogen-free" characteristics of copper cladding are defined for the first time: The definition standard of chlorine content or bromine content less than 0.09wt % was later adopted by the EU, the United States and other countries in drafting relevant or similar standards; The IEC also includes this definition in its standard range o the standard of IPC-4101 Specification for Rigid and Multilayer Printed Board Substrates promulgated by IPC in 2000 also includes the halogen-free standard value IPC-4101/92, 93,94,95

② Limit the use:

Permit the intentional use of a particular chemical substance or permit it to exist in the form of an impurity containing a large amount, the amount of which or the amount of which the use limit has a limited use.

Containment control: Use that allows the intentional use of a particular chemical substance without limiting its content, but requires reporting of its content, where it is contained, and what it is used for.

3, six substances ICP detection method

There are a variety of detection methods for the six substances, which can be divided into soluble and insoluble test methods. The detection method should be clearly defined when sending for detection, otherwise it will be deemed invalid.

4. How to apply for testing of PCB products

4.1 Raw materials and the ICP test report provided by the raw materials manufacturer (the content of the report shall correspond to the list of raw materials, and the validity period of the report shall be 1 year). These ICP test reports must be published by a recognized third party.

4.2 Test Application Process

4.2.1 Request for Application Form

Either of the above two tests should be contacted and requested (application form, procedures for applying for testing, quotations for testing products, and testing cycles).