How to quickly judge the quality of PCB

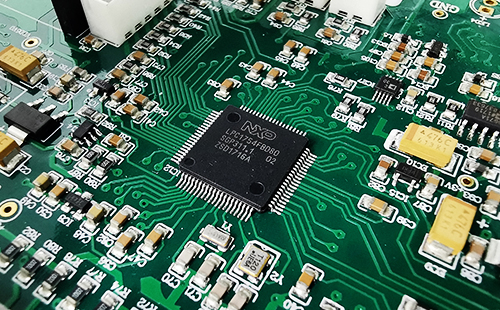

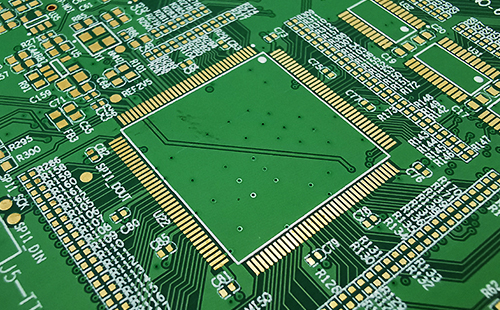

The names of circuit boards include: ceramic circuit board, alumina ceramic circuit board, aluminum nitride ceramic circuit board, circuit board, PCB board, aluminum substrate, high-frequency board, thick copper plate, impedance board, PCB, ultra-thin circuit board, ultra-thin circuit board, printed (copper etching technology) circuit board, etc. The circuit board makes the circuit miniature and intuitive, which plays an important role in the mass production of fixed circuits and the optimization of the layout of electrical appliances. The circuit board can be called printed circuit board or printed circuit board, and the English name is printed circuit board (PCB), flexible printed circuit board (FPC circuit board is also called flexible circuit board) FPC circuit board (FPC circuit board is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the substrate. It has the characteristics of high wiring density, light weight, thin thickness and good bending.) The birth and development of FPC and PCB (reechas, Soft and hard combination plate) gave birth to this new product. Therefore, the soft and hard combination board is a circuit board with FPC characteristics and PCB characteristics formed by combining the flexible circuit board and the hard circuit board according to relevant process requirements after pressing and other processes.

When we get a PCB and have no other testing tools at hand, how can we quickly judge the quality of a PCB? We can refer to the following six points:

1. The size and thickness of PCB must be consistent with the specified size and thickness without deviation. The board surface shall be free of defects, deformation, peeling, scratching, open circuit, short circuit, oxidation, whitening, yellowing, unclean etching or excessive etching, and the board surface shall be free of stains, copper particles and other impurities.

2. The ink shall be covered evenly and glossy, without falling off, scratching, copper exposure, offset, hanging, etc.

3. The symbols and letters printed on silk screen are clear, and there are no defects such as missing, blurring, reverse printing, and offset.

4. The carbon film shall be free of defects, printing deviation, short circuit, open circuit, reverse printing, etc.

5. PCB bottom plate shall be formed without leakage, offset, hole collapse, flaring, plug hole, beer explosion, beer inversion, crushing and other phenomena.

6. Whether the edges of PCB board are smooth. If it is V-CUT process, it is necessary to pay attention to whether V-CUT slot causes wire breakage, and whether both sides are symmetrical.

Generally, through these 6 points, you can quickly judge whether a PCB is good or bad.