FPC is the abbreviation of Flexible Printed Circuit in English, also known as flexible circuit board, flexible printed circuit board, flexible circuit board, or FPC for short; The circuit board has the advantages of high wiring density, light weight, thin thickness, etc. It is widely used in mobile phones, laptops, PDAs, digital video cameras, LCMs and many other products.

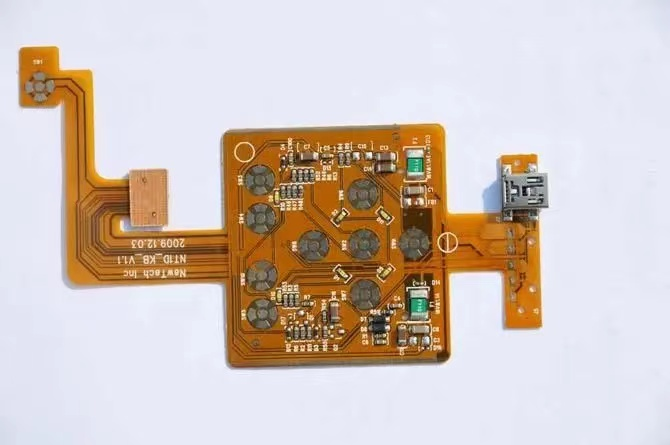

Double layer plate FPC

Characteristics of FPC circuit board: FPC circuit board has the characteristics of high wiring density, light weight, thin thickness, etc.

Use of FPC circuit board

FPC circuit board uses electronic products such as Skyphone, laptop, PDA, digital camera and LCM. FPC circuit board is a highly reliable and excellent flexible printed circuit made of polyimide or polyester film. The flexible circuit board can be divided into two categories according to the combination mode of base material and copper foil: adhesive flexible board and non adhesive flexible board. The price of adhesive free flexible board is much higher than that of adhesive flexible board, but its flexibility, adhesion between copper foil and substrate, flatness of bonding pad and other parameters are also better than that of adhesive flexible board. Therefore, it is generally only used for those occasions with high requirements; Because the price of flexible board with glue is too high, most flexible boards on the market are still flexible boards with glue. As the flexible plate is mainly used in the situation where bending is required, if the design or process is unreasonable, it is easy to produce microcracks, open welding and other defects. The structure of flexible circuit board and its special requirements on design and process are as follows:

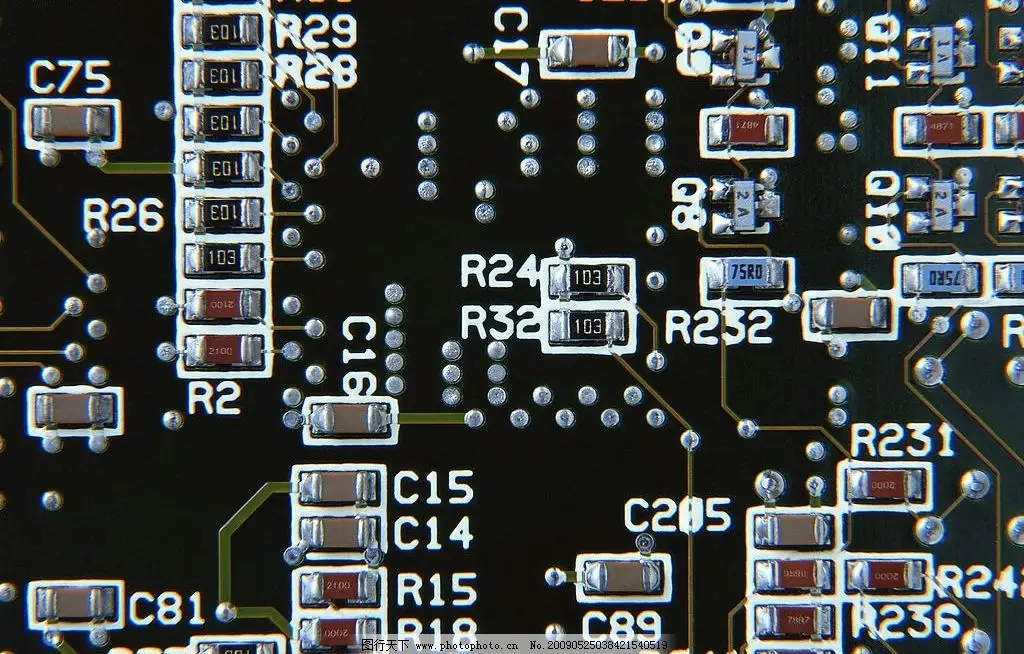

Structure of FPC plate

According to the number of layers, it can be divided into single-layer board, double-layer board, multilayer board, etc. The structure of single-layer plate is the simplest flexible plate. Generally, the base material+transparent adhesive+copper foil is a set of purchased raw materials, while the protective film+transparent adhesive is another kind of purchased raw materials. First, the copper foil needs to be etched to obtain the required circuit, and the protective film needs to be drilled to expose the corresponding bonding pad. After cleaning, use the rolling method to combine the two. Then, the exposed bonding pad shall be electroplated with gold or tin for protection. In this way, the big board is ready. Generally, small circuit boards should be stamped into corresponding shapes. There are also those who print solder mask directly on copper foil without using protective film. This will lower the cost, but the mechanical strength of the circuit board will become worse. Unless the strength requirement is not high but the price needs to be as low as possible, it is better to apply the protective film.

The structure of double-layer board is that when the circuit is too complex, the single-layer board cannot be wired, or copper foil is required for grounding shielding, double-layer board or even multilayer board is required. The most typical difference between multilayer board and single-layer board is that the via structure is added to connect each layer of copper foil. Generally, the first processing process of substrate+transparent adhesive+copper foil is to make vias. First, drill holes on the base material and copper foil. After cleaning, coat a certain thickness of copper, and then the through-hole is ready. After that, the manufacturing process is almost the same as that of single layer board.

application area

MP3, MP4 player, portable CD player, home VCD, DVD, digital camera, mobile phone and mobile phone battery, medical, automotive, aerospace and military fields. Flexible copper clad laminate (FPC) with flexible function and epoxy resin as the base material is being used more and more widely due to its special function, and is becoming an important variety of epoxy resin based copper clad laminate. But China started late and needs to catch up.

Since the realization of industrial production of epoxy flexible printed circuit board, it has experienced more than 30 years of development. Since the 1970s, FPC has entered into a truly industrialized mass production. Until the late 1980s, due to the advent and application of a new type of polyimide film materials, flexible printed circuit boards (FPCs) made FPCs appear as adhesive free FPCs (generally referred to as "two-layer FPCs"). In the 1990s, the world developed a photosensitive coating corresponding to high-density circuits, which made a great change in the design of FPC. Due to the opening up of new application fields, the concept of its product form has changed a lot, including expanding it to a wider range of substrates for TAB and COB. In the second half of the 1990s, high-density FPC began to enter large-scale industrial production. Its circuit graphics are rapidly developing to a more detailed level, and the market demand for high-density FPC is also growing rapidly.