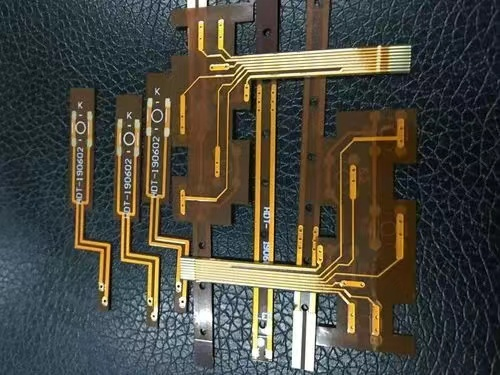

An ordinary FPC is mainly composed of two materials: base material+protective film. First, the base material is mainly composed of PI or PET+glue+copper. PI is a "polyimide" insulating resin material, which is characterized by high temperature resistance, good bending performance, and good reliability of the products. It is more than twice the price of PET. It is the main material of FPC. PET is a "polyester" insulating resin material, which is just the opposite of PI. Generally, FPC plants have rarely used it.

As we all know, copper is a conductor, and the role of glue is to bond copper with PI or PET, and finally make the FPC substrate, that is, substrate or backplane, which is equivalent to the PCB substrate. Let's talk about the protective film again. The protective film refers to the insulation layer on the surface of FPC. After the line is completed on the substrate, an insulation layer similar to the PCB ink function is attached to prevent the line from oxidation and short circuit. It is also composed of glue and PI insulation layer.

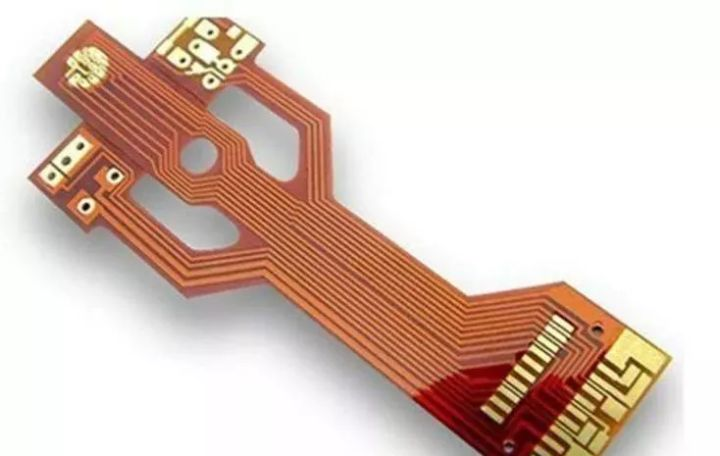

FPC is the abbreviation of flexible circuit board. It is a highly reliable and excellent flexible printed circuit board. It has high assembly density, small size and light weight. Because high-density assembly and fewer connections between components (including parts) increase reliability; It can increase the wiring layer, and then increase the design flexibility; It can also form the impedance of the circuit, form a high-speed transmission circuit with a certain degree, set the circuit and electromagnetic shielding layer, and install metal core layers to meet the special thermal insulation and other functions and needs; Easy installation and high reliability. It is mainly used in the electronic industry. What are the advantages of this widely used flexible circuit board?

Four points are summarized as follows:

First advantage: The volume of the FPC is smaller than that of the hard board, which can effectively reduce the product volume and increase the convenience of carrying.

The second advantage: the weight is lighter than the hard board, which can reduce the weight of the final product.

The third advantage: the thickness is thinner than the hard board, which can improve the flexibility, thus strengthening the assembly of three-dimensional space in the limited space.

The fourth advantage: the assembly time is very short. All lines in the circuit are configured, eliminating the connection of redundant cables.