At present, there are four kinds of FPC: single-sided, double-sided, multi-layer flexible board and rigid flexible board.

1. Single sided flexible board is the printed board with the lowest cost and low electrical performance requirements. In case of single-sided wiring, single-sided flexible board shall be selected. The utility model has a layer of chemically etched conductive patterns, and the conductive pattern layer on the flexible insulating substrate is a calendered copper foil. The insulating substrate can be polyimide, polyethylene terephthalate, aramid fiber ester and polyvinyl chloride.

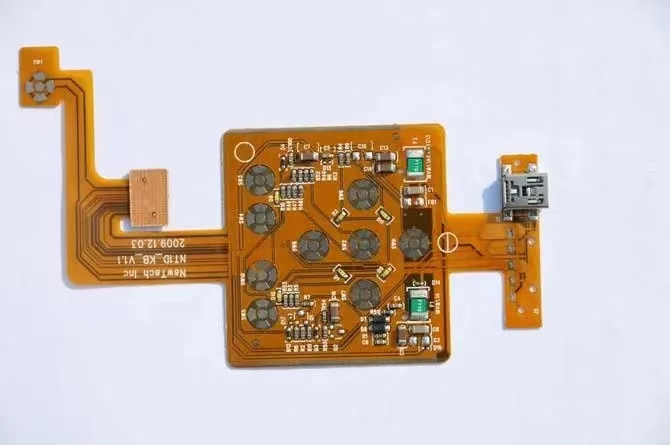

2. The double-sided flexible board is a conductive pattern made of a layer of etching on both sides of the insulating base film. The metallized hole connects the figures on both sides of the insulating material to form a conductive path to meet the design and use functions of flexibility. The covering film can protect the single and double sided wires and indicate the location of the components.

3. Multilayer flexible board is to laminate three or more layers of single-sided or double-sided flexible circuits together, form metallized holes by drilling L and electroplating, and form conductive paths between different layers. In this way, complex welding processes are not required. Multilayer pcbs have huge functional differences in terms of higher reliability, better thermal conductivity and more convenient assembly performance. When designing the layout, the interaction of assembly size, number of layers and flexibility should be considered.

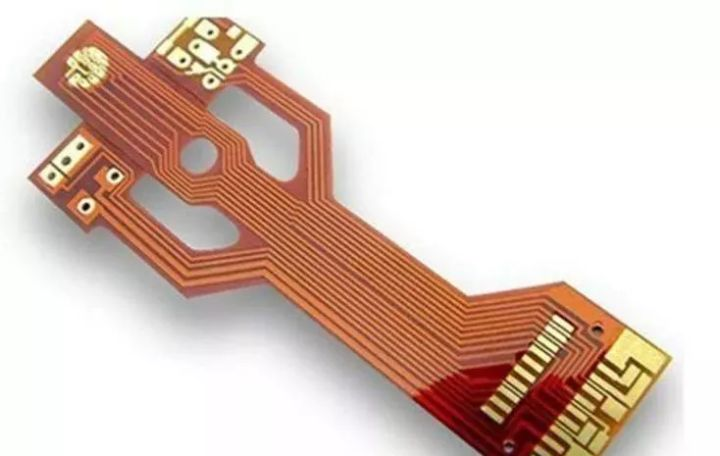

4. The traditional rigid flexible plate is composed of rigid and flexible base plates selectively pressed together. The structure is compact, and the conductive connection is formed by metallized nickel L. If a printed circuit board has both front and back components, rigid flexible board is a good choice. However, if all the components are on one side, it will be more economical to choose double-sided flexible board and laminate a layer of FR4 reinforcement material on its back.

5. The flexible circuit with hybrid structure is a multilayer board, and the conductive layer is composed of different metals. An 8-layer board uses FR-4 as the medium of the inner layer and polyimide as the medium of the outer layer. Leads stretch out from three different directions of the main board. Each lead is made of different metals. Constantan alloy, copper and gold are used as independent leads. This kind of hybrid structure is mostly used in the case of the relationship between electrical signal conversion and heat conversion and the harsh low temperature of electrical performance, which is the only feasible solution.

After years of progress, softboards are no longer a one-of-a-kind accessory. FPC can be seen in many medical devices.

1. The use of medical device buttons and FPC softboards on the buttons is also a large-scale model. Although medical buttons and other buttons are a test of product sensitivity. However, the requirements for the number of repeatable keystrokes are very high in the medical field. The softboard can be used dynamically for millions or hundreds of millions of times according to the product requirements. These capabilities are the main aspects of softboards' popularity in terms of keys.

2. On the screen of medical equipment, the connecting flat cables on the screen are all FPC soft boards, not only for medical purposes, but also for almost all screen displays. This is an affirmation of the bending and flexure of the soft boards.

3. The gastroscope circuit board has been developed for a long time through technology, but due to the poor coordination of the bending capacity and rigidity of the circuit board at that time, the catheter could not be well operated by medical personnel. However, the FPC soft board used inside the gastroscope now has high bending and bending performance only after years of verification and production experience.