What is the relationship between multi-layer PCB circuit boards and medium and high TG sheet types?

Is indispensable! are inseparable! are complementary!

Take a look at the reasons below and you will understand!

1. What fields are multi-layer PCB circuit boards generally used in?

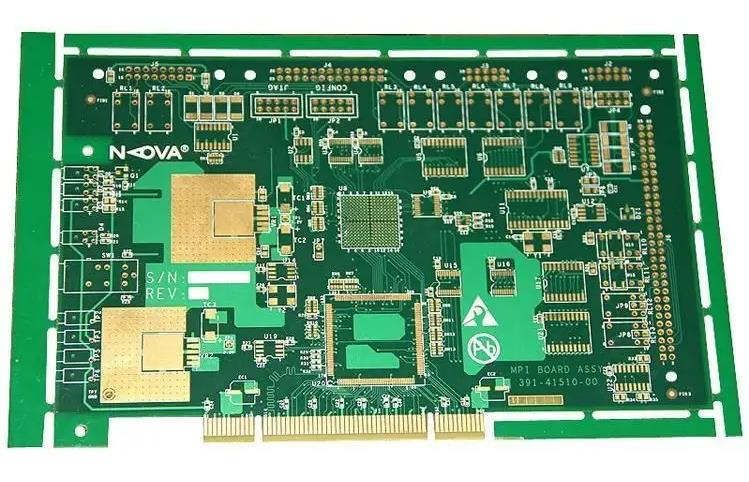

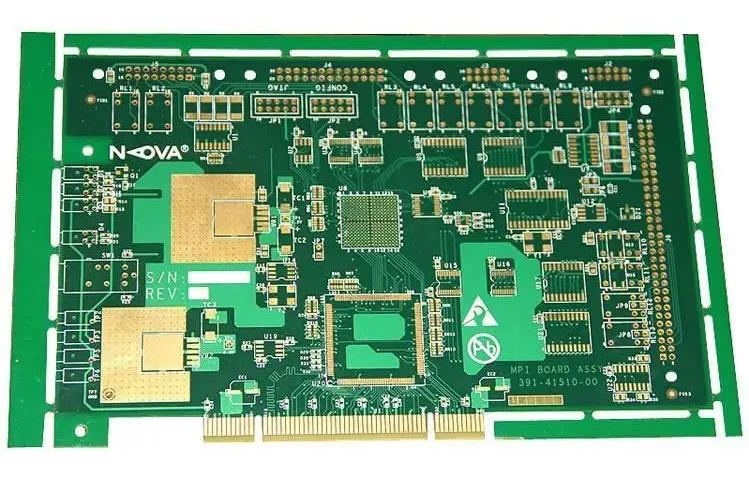

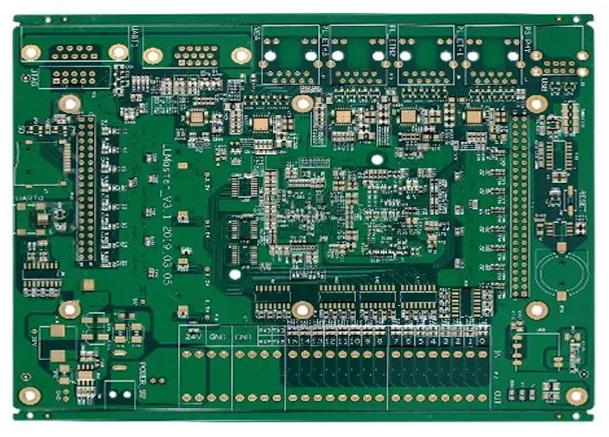

Multilayer PCB circuit boards are generally used in communication equipment, medical equipment, industrial control, security, automotive electronics, aviation, computer peripherals and other fields; as the "core main force" in these fields, with the continuous increase of product functions, more and more circuits are The denser it is, the higher the quality of the board is correspondingly required by the market, and the customer demand for medium and high TG circuit boards is continuously increasing.

2, the particularity of multi-layer PCB circuit boards

Ordinary PCB boards will have problems such as deformation at high temperatures, and at the same time, mechanical and electrical properties may also drop sharply, reducing the service life of the product. The application field of multi-layer PCB circuit boards is generally located in the mid-to-high-end technology industry. This particularity directly requires the sheet material to have high stability, high chemical resistance, and can withstand high temperature, high humidity, etc...

Therefore, the production of multi-layer PCB circuit boards should use at least TG150 or more plates, so as to ensure that the circuit boards are less affected by external factors during the application process and prolong the service life of the products.

3. Stability and high reliability of high TG sheet types

What is TG value?

TG value: TG is the maximum temperature at which the sheet maintains its rigidity. The TG value refers to the transition of the amorphous polymer (including the amorphous part of the crystalline polymer) from the glassy state to the highly elastic state (rubber state). temperature at the transition.

The TG value is the critical temperature at which the substrate melts from a solid state to a rubbery fluid.

The level of TG value is directly related to the stability and reliability of PCB products. The higher the TG value of the sheet, the stronger the stability and reliability.

High TG sheet has the following advantages:

(1) High heat resistance, which can reduce the floating of PCB pads during infrared heat fusion, welding and thermal shock.

(2) Low coefficient of thermal expansion (low CTE) can reduce warpage caused by temperature factors and reduce copper breakage at the corners of holes caused by thermal expansion, especially in multi-layer PCB boards with eight or more layers, plated through holes The performance is better than the general TG value of the PCB board.

(3) It has excellent chemical resistance, so that the PCB board can keep its performance intact under the immersion of many chemical solutions during the wet treatment process.

Under normal circumstances, the quality, performance and reliability of PCB circuit boards made of medium and high TG boards are better than those of low TG boards.

Therefore, we have insisted on using high-quality boards for many years, carefully committed to providing our customers with batch and proofing services for medium and high TG circuit boards, and actively providing high-quality Shengyi boards and Kingboard Class A boards;

Of course, batch and proofing of special plates (aluminum substrates, copper substrates, Rogers high-frequency plates, FPC flexible plates, etc.) are not a problem.