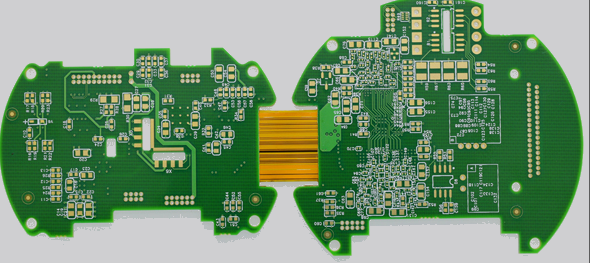

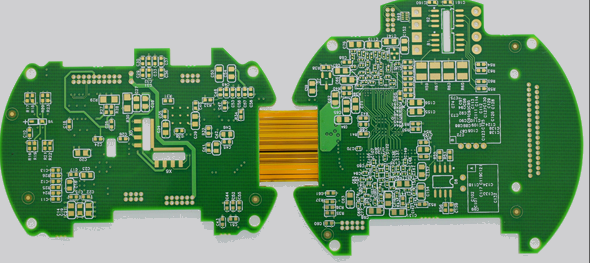

FPCs are widely used in various electronic products and equipment, such as commercial electronic equipment, automobile dashboard, printer, hard disk drive, floppy disk drive, fax machine, mobile phone, general telephone, notebook computer, camera, camera, CD-ROM, hard disk, watch, computer, camera, medical instrument and equipment.

1、 Liquid Crystal Polymer (LCP) insulating substrate

In addition to the research and development of new substrates, adhesive free flexible circuit boards, and thin copper... Is one of the means. In the base material part, PI films have been used since the 1960s because of their excellent electrical, chemical, mechanical and heat resistance characteristics required for circuit substrates and structures. However, with the rapid development of circuit density and high frequency, PI films are not enough, and the research and development of new thin, high flexural, high-density (high dimensional stability) substrates has become a trend of the times.

Among them, the development of liquid crystal polymer (LCP) is the most eye-catching. Compared with traditional PI films, LCP has comparative advantages in high-frequency and high-speed signal transmission, and has low dielectric constant and moisture absorption characteristics (1/10 of PI). Low water absorption can achieve higher reliability of thinner substrate and substrate construction. In addition, LCP has good thermal plasticity, which is beneficial to environmental recovery, and is considered to be the most likely to replace the potential threat of traditional PI substrate.

However, the current price of LCP is high, and problems such as compatibility with existing processes, adhesion with copper foil, high temperature processability, and material orientation need to be overcome. It is difficult to threaten the stable mainstream status of PI substrate in the short term.

However, it can be predicted that being thin and short will be the trend of electronic products in the future. Therefore, the thickness of insulating materials for flexible circuit boards has been rapidly lowered from the typical FCCL of 25 um in the past to 12.5 um, or even to less than 10 um. Reducing the thickness of flexible circuit boards to 10 um will not only make the appearance of circuit boards lighter and thinner, but also improve the flexibility by more than 40%. However, due to the low manufacturing yield below 10um, it is bound to reflect the high cost expenditure, which indirectly affects the key to whether the thickness of PI film substrate can be developed below 10um.

2、 Non adhesive FPC gradually replaces adhesive FPC

The traditional flexible circuit board substrates generally use adhesives, but the thermal properties and reliability of the adhesive material characteristics are poor. The use of adhesive free flexible circuit board (2L-FCCL) will improve its electrical and thermal properties.

The adhesive free FPC (2L-FCCL) has the advantage of being thin compared with the traditional adhesive free FPC (3L-FCCL). In recent years, because the manufacturing yield of the adhesive free FPC (2L-FCCL) has increased, the production technology has improved, and the production volume has increased significantly, the price of the adhesive free FPC (2L-FCCL) has gradually closed to the market of the adhesive free FPC (3L-FCCL), and the market proportion between the two has gradually narrowed, The market forecast shows that there is a market trend of squeezing to replace the flexible circuit board of the following dosage form (2L-FCCL).

3、 Thin copper flexible circuit board with higher density

In addition, thin copper is also one of the methods of thinning the substrate. The rolled copper foil (RA Foil) is mainly the conductive material of FPCs. The thickness of the commonly used rolled copper foil in the market can be divided into mainstream specifications such as 1oz and 1/2oz. At present, the mainstream copper foil of FPCs has gradually shifted to a thinner 1/3oz specification. After the thin copper Foil is developed, it has a higher density feature.