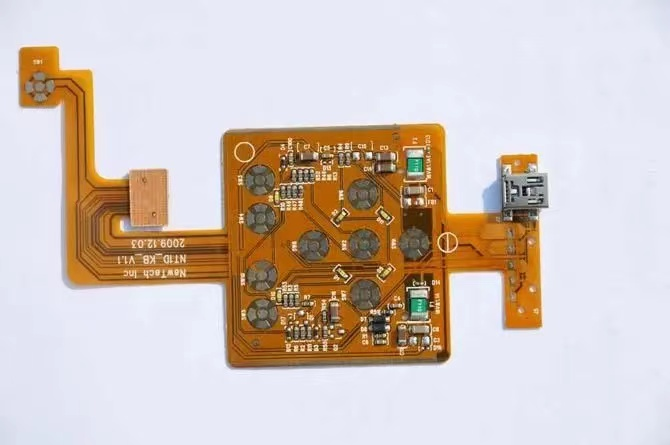

Pcb factory: FCT function test must read

To put it simply, FCT is an online test, which mainly checks whether the circuit board components after PCBA processing are inserted incorrectly and whether the original price parameters are normal; FCT is an online function test, which mainly checks whether the function of the circuit board is normal. The two tests have their own emphasis. After passing the FCT test, you can confirm that the circuit board is OK and can be used normally.

In professional terms, FCT refers to a test method that provides a simulated operating environment (excitation and load) for the test target board (UUT: Unit Under Test) to work in various design states, so as to obtain parameters of each state to verify the function of UUT. To put it simply, the UUT is loaded with appropriate excitation to measure whether the output response meets the requirements. It generally refers to the functional test of PCBA.

Basic overview

The full English name of FCT is Functional Circuit Test, which generally refers to the functional test after PCBA is powered on, including the measurement of voltage, current, power, power factor, frequency, duty cycle, position measurement, LED brightness and color recognition, LCD character and color recognition, sound recognition, temperature measurement and control, pressure measurement and control, precision micro motion control, FLASH and EEPROM online burning and other functional parameters. It refers to a test method that provides a simulated running environment (excitation and load) for the test target board (UUT: UnitUnderTest) to work in various design states, so as to obtain parameters of each state to verify the function of UUT. To put it simply, UUT is loaded with appropriate excitation and load, and its output response is measured to see if it meets the design requirements.

Classification of functional tests

According to different control modes, it can be divided into:

(1) Manual control function test

(2) Semi automatic control function test

(3) Full automatic control function test

The earliest functional tests were mainly manual and semi-automatic. Even now, for the function test of some simple boards under test, based on the consideration of simplifying the design and reducing the production cost, manual or semi-automatic test schemes are sometimes used. With the rapid development of science and technology, in order to save production costs and improve production efficiency, most of the current functional tests use fully automated test solutions.

According to the type of controller, it can be divided into:

(1) MCU control mode

MCU control mode can be regarded as simple embedded control. The characteristics of MCU and embedded CPU control mode are as follows:

A. Fast test execution

B Simple and clear test operation

C. Special circuits and programs are required for data display and output

D The test plan is highly targeted

E Convenient modification of test software

(2) Embedded CPU control mode

(3) PC control mode

The control mode of PC is the most widely used FCT test mode at present, mainly because:

A PC technology has become the basic general technology in today's society

B PC is cheap

C The data output and file processing of test results can be easily implemented on the PC operating system

D. The operation of the test software is closer to the user's operating habits

E Special test program development software

(4) PLC control mode

The control mode of PLC is also a commonly used FCT development mode at present. Its focus is on the control of the sensing part, while the measurement function of the board under test is weak. This is because PLC is specialized in industrial control.

Composition of functional test system

The system composition of PCBA function test is mainly divided into:

(1) System Control Center

(2) Control execution part

(3) Parameter measurement part

(4) Data processing and output

System control center: This part is generally composed of PC, MCU, ARM and other small or medium-sized central processors. It is the core component of the entire test system. Its main role is to control the running state of the entire test process, judge and record the test content and results of each step, and finally obtain the test results.

Control execution part: The control execution part is mainly composed of I/O parts. It is the sensing and executing mechanism of the logic action in the test process. The system uses it to build various test environments and realize the test functions.

Parameter measurement part: the measurement part is mainly composed of special measurement boards and meters, which mainly completes the collection of various analog or digital quantities during the test process. Sometimes we call it the data collection part.

Data processing and output: each step and the final test results are the purpose of our entire test. How to store and output these results and data is more convenient for us to effectively control the quality of PCBA products, which is the responsibility of the data processing and output part.

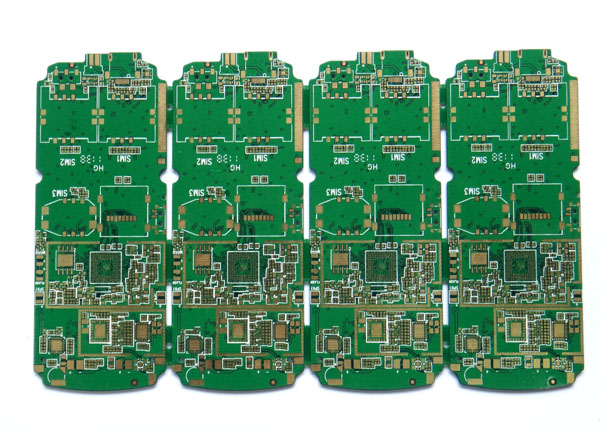

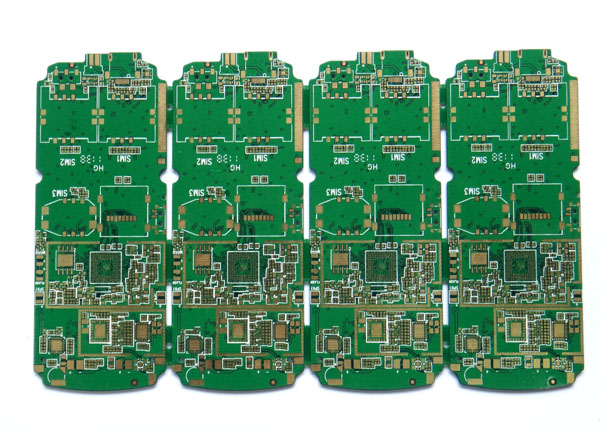

Cause of FCT

PCBA is called real circuit board in Chinese. In the process of mass production of PCBA, it is impossible to ensure that all PCBA produced are intact due to the operating state of the equipment and the human factors of the operator. This requires adding various testing equipment and tools at the end of production to ensure that all real circuit boards delivered are completely consistent with the specifications and parameters of the design, which results in ICT, AOI, X-Ray, Boundary Scan FCT and other testing methods.