Improve the color difference on both sides of PCB wet film and text?

PCB manufacturing, PCB design and PCBA processing manufacturers explain how to improve the wet film of PCB and the color difference on both sides of the text

With the development of science and technology, people have higher and higher requirements for the quality of PCB. In the past, there will always be problems like this and that. We find that the green paint function has other effects besides preventing the circuit from oxidation and welding short circuit? How to improve the color difference between the wet film of PCB and the two sides behind the text? How can the copper surface not be oxidized? Now I will explain how to improve the wet film of PCB and the color difference of the two sides behind the text?

How to improve the color difference between the wet film and the two sides of the text on PCB?

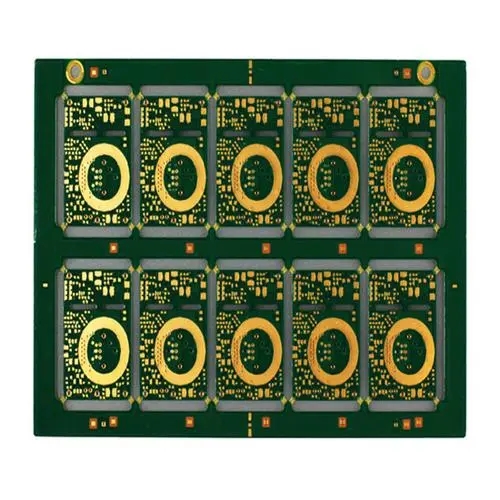

The main functions of green paint are oxidation resistance and solder stop. In addition, because it is also a dielectric material, it will have a certain impact on the impedance. It is difficult to solve the color difference problem of circuit board, especially when the copper area of the board is different. Because of the color difference, it often comes from the color reflection state of the circuit board surface. If there is a large difference in copper area, there is no way to change the reality, and the color difference will certainly exist. Therefore, color difference problems should focus on whether there is discoloration of printing ink, copper surface and plates that should not occur. Other problems should not be important quality problems. Of course, some people simply use dark ink, which can cover up the ugly. As for the copper surface oxidation, the surface should be kept dry and maintained continuously after the coating pretreatment and drying, especially not stacked together before the circuit boards are really dry. Because this kind of stack will make the residual hot water gas cannot be removed, which will soon affect the copper surface and cause oxidation.

In the general production method of welding stop paint, the ink will be coated on one side first and then pre dried, and then the second side will be coated. If the drying time is not very long, the color of the copper surface will not change greatly. But more or less, the surface color must be a little deeper. This problem seems to be difficult to avoid if the existing manufacturing process is used. Therefore, some manufacturers will separate the two sides of the circuit board. First, coating, pre drying, exposure, development and hardening of one side will be carried out, and then a pre-treatment will be carried out to make the copper on the other side show a fresh copper surface, and then an overall manufacturing process will be carried out. Although this method can improve the color of copper surface, it has a negative impact on size control, exposure alignment, flatness of board surface, and processing costs, so it is not practical.

At present, many circuit board manufacturers begin to use welding stop paint spraying treatment, which can reduce the risk of color difference of twice baking. As for the problems that cannot be overcome in practice, it is recommended to discuss the actual functionality with the customer. As long as there is no problem with the function, color difference should not be the main consideration of quality.

PCB manufacturers, PCB designers and PCBA manufacturers will explain how to improve the wet film of PCB and the color difference on both sides of the text.