The small editor explains the common faults and solutions of PCB film

PCBA processing is to connect various electronic components on PCB board through surface mount (SMT), plug-in (DIP) and other electronic assemblies. PCBA process flow mainly includes SMT, AOI, DIP, FCT testing and other processes. Due to the size difference of electronic components, there will be different processes and requirements in assembly and insertion. The assembly density of PCBA is relatively high, and the small size and light weight of electronic products also have certain changes and requirements in mounting. The reliability, seismic resistance and excellent weldability of the products have high requirements for the hardware and software facilities of PCBA processing.

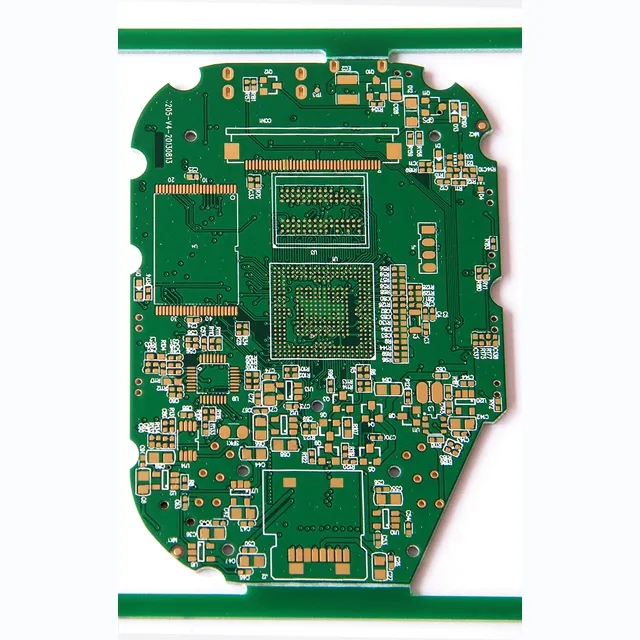

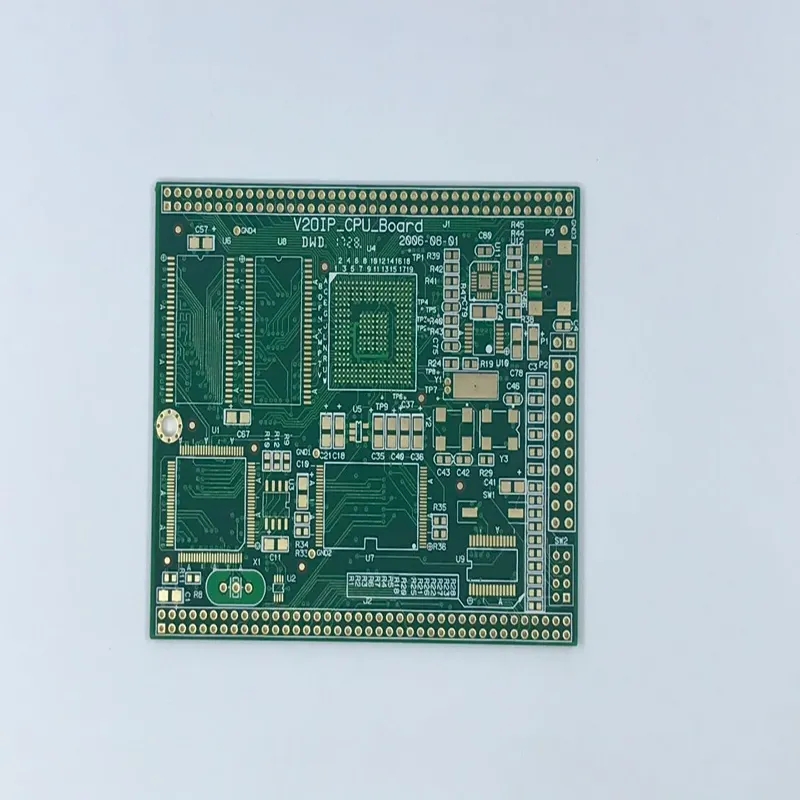

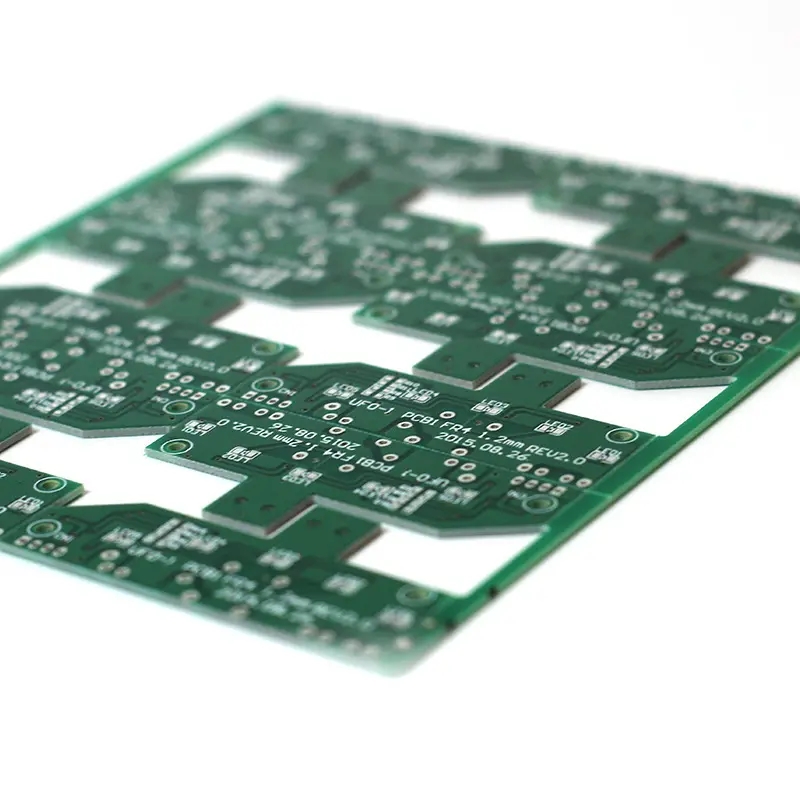

Printed circuit board (PCB), also known as printed circuit board (PCB), is an important electronic component, a support for electronic components, and a provider of circuit connection for electronic components. Because it is made by electronic printing technology, it is called "printed" circuit board. Before the appearance of printed circuit board, the interconnection between electronic components depended on the direct connection of wires to form a complete circuit. Now, the circuit board only exists as an effective experimental tool, while the printed circuit board has become the absolute dominant position in the electronic industry.

In the PCB manufacturing process, some PCB film mounting failures are commonly encountered when using PCB dry film technology. The following sections introduce common PCB film mounting failures and solutions.

PCB pasting machine

1. The dry film is not firmly stuck on the copper foil

(1) The surface of copper foil is not clean, and there is oil stain or oxide layer. Clean the board surface again and wear gloves.

(2) The solvent in the dry film solvent volatilizes and deteriorates. Store at low temperature, and do not use expired dry film.

(3) Fast transmission speed, low PCB film temperature. Change PCB film speed and PCB film temperature.

(4) The ambient humidity is too low. Keep the relative humidity of the production environment at 50%.

2. Bubbles appear between the dry film and the copper foil surface

(1) The copper foil surface is uneven, with pits and scratches. Increase the PCB film mounting pressure, and handle the plate with care.

(2) The surface of the hot pressing roller is uneven, with pits and adhesive film drilling dirt. Pay attention to the flatness of the surface of the hot pressing roll.

(3) If the temperature of PCB film is too high, reduce the temperature of PCB film.

3. Dry film wrinkling

(1) The dry film is too sticky, please put the board carefully.

(2) The board is too hot before PCB film pasting, and the preheating temperature of the board should not be too high.

4. Residual glue

(1) The dry film quality is poor. Replace the dry film.

(2) The exposure time is too long, shorten the exposure time.

(3) If the developer fails, change the developer.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the common faults and solutions of PCB film.