Do you know the cutting process of circuit board factory

The circuit board manufacturer, circuit board designer and PCBA manufacturer explain the cutting process of the circuit board factory

The production process of the circuit board is not complicated, but we must be careful. Each program is strictly controlled. The following section will introduce the cutting process of Shenzhen Circuit Board Factory.

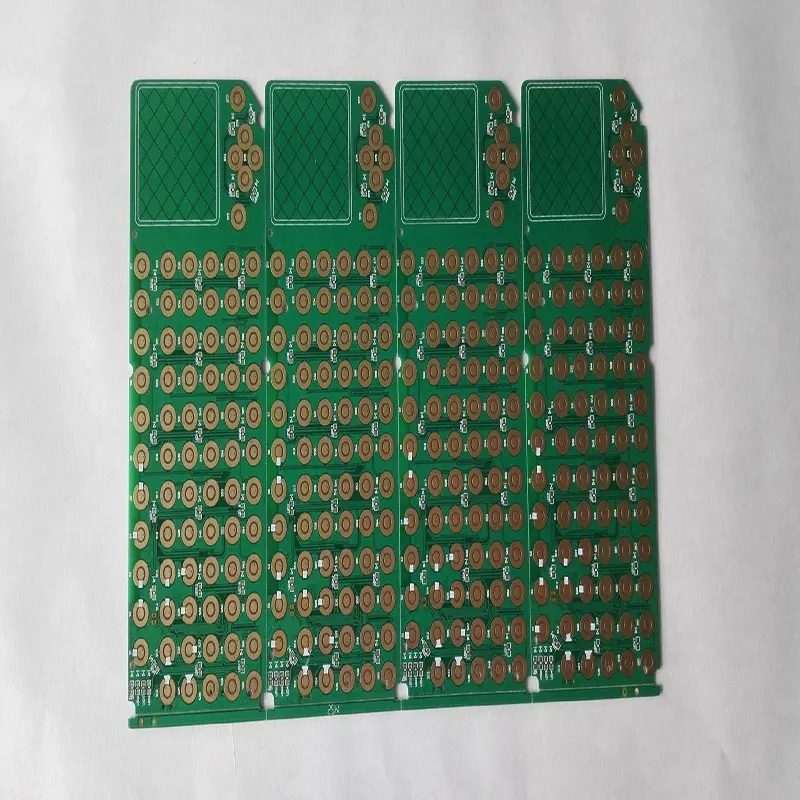

Cutting is to cut large size plates into the size required for actual production. It is a very important start in our circuit board production process. Our Shenzhen circuit board factory is more and more concentrated, and circuit board production has become a part of the entire industry. Let's look at it with the pace of small knitting.

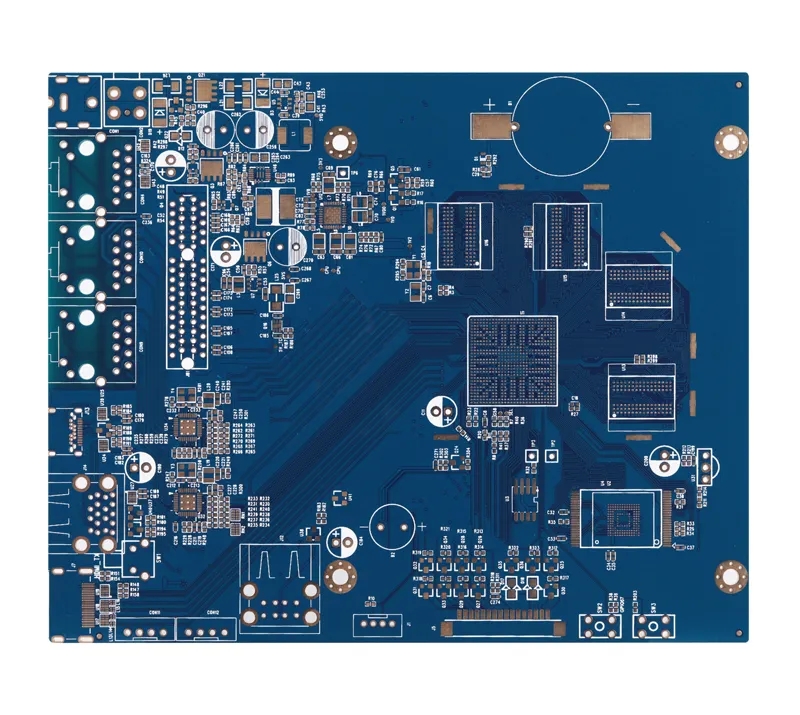

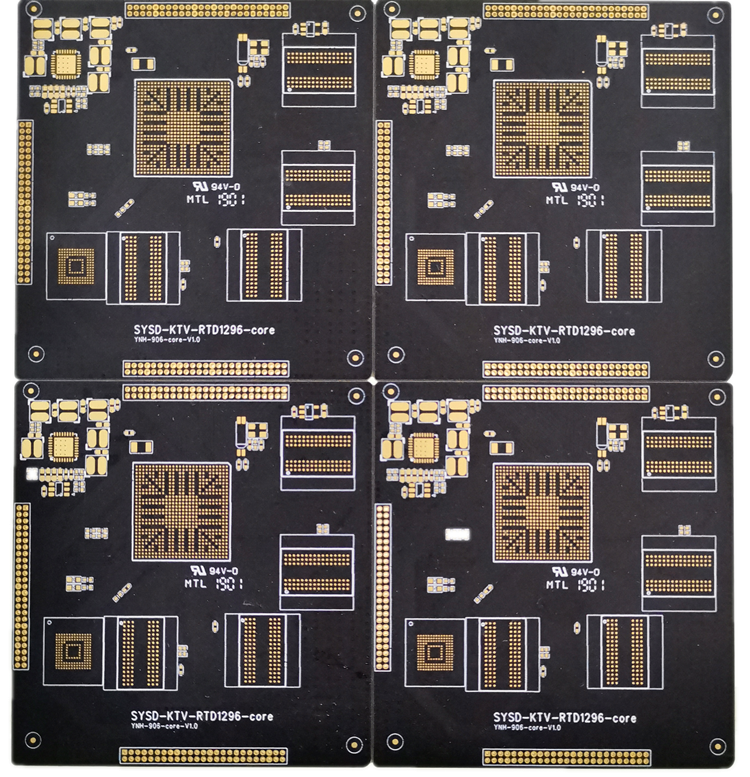

Circuit board factory cutting is to cut the large size raw material (sheet) of copper clad plate (CCL) into the production board of small size (panel), and conduct fillet and edge grinding treatment to see that the sharp corners and burrs of the board scratch the printed board or operators during processing, and then dry the board to eliminate the internal stress in the CCL, so as to reduce the deformation of the board in the subsequent processing, Our PCB factories in Shenzhen use the most raw materials of CCL when cutting.

Cutting Process of Shenzhen Circuit Board Factory

What is the legendary copper clad laminate in Shenzhen PCB Factory, where PCB is concentrated? Copper clad laminate is made by dipping the strengthening material into resin, covering one or both sides with copper foil, and pressing_ Material Science. It is mainly used for conducting, insulating and supporting. The English name is Copper Clad Uminate, which is abbreviated as CCt. The full quard copper clad laminate is called copper clad laminate for short. It can be one side or both sides covered with copper foil, called single-sided copper clad plate or double-sided copper clad plate.

When cutting, our Shenzhen Circuit Board Factory will use the cutting machine. Each board will be cut by the machine and appear in front of everyone. After the blade of the cutting knife is blunt, it can be removed for grinding and then reused. The service life of the cutting knife is related to the type of cutting. Compared with the cutting paper based clad plate and thin copper foil clad plate, the service life of the cutting knife is undoubtedly shorter. Besides, the blade gap operated by the cutting machine is also related to the material of the cutting substrate.

The operators of our Shenzhen Circuit Board Factory are very dedicated. Every time the cutter changes, the accumulated cutting area must be recorded from 0, and the cutter will be replaced after reaching the specified area; In addition, if there is obvious warping or serious burr on the plate edge during cutting, the cutting knife should also be checked or replaced to prevent problems of the plate caused by errors.

Behind every neat circuit board in Shenzhen Circuit Board Factory, there is a cutting machine that pays silently. Have you mastered the cutting process of the circuit board factory above?

Circuit board manufacturers, circuit board designers and PCBA processors will explain the cutting process of the circuit board factory.