Advantages of PCB high-frequency board and its production and processing methods

1、 High efficiency

Generally speaking, the consumption of high-frequency circuit boards is lower than that of other circuit boards due to their small dielectric constant. Under such excellent congenital conditions, induction heating technology at the forefront of scientific and technological development can also meet the needs of target heating, thus making the efficiency of high-frequency circuit boards very high. Of course, while pursuing efficiency, we should not abandon environmental protection.

2、 Fast

As we all know, the transmission speed is proportional to the dielectric constant. In electrical principle, the transmission speed is inversely proportional to the square root of the dielectric constant, that is, the larger the dielectric constant is, the slower the transmission speed is; The smaller the dielectric constant, the faster the transmission speed. This is one of the reasons why high frequency PCB boards are popular. They are made of special materials, which can ensure the small dielectric constant and the relatively stable operation of PCB boards while ensuring the transmission speed.

3、 High controllability

High frequency circuit boards, which are widely used in various industries for the heating treatment of precision metal materials, can not only realize the heating of parts with different depths, but also focus on local characteristics in the process of their field. Whether it is surface or deep level, centralized or decentralized heating methods, they can be easily completed.

4、 Strong tolerance

The environment affects the composition of the medium, so there are still some requirements for the environment of high-frequency circuit boards, especially in the south where there are many humid days. High frequency circuit boards can well adapt to such an environment. High frequency circuit boards made of materials with very low water absorption can challenge such an environment. At the same time, it is better to make PCB circuit boards have the advantages of resistance to chemical corrosion, so that they can withstand moisture and high temperature in a humid environment, and have great peel strength.

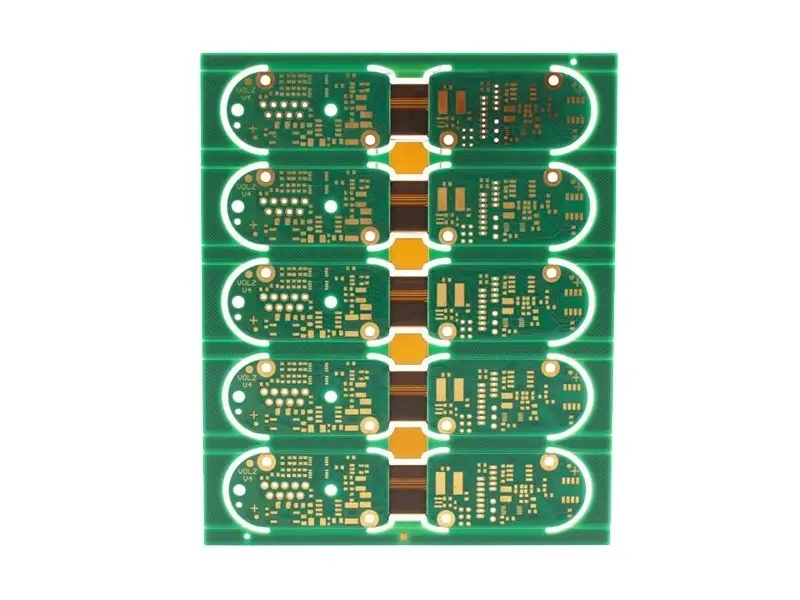

Production, Processing and Application of PCB High Frequency Board

Application fields of PCB high-frequency board:

1. Mobile communication products;

2. Power amplifier, low noise amplifier, etc;

3. Power divider, coupler, duplexer, filter and other passive components;

4. High frequency electronic equipment is the development trend in automotive anti-collision system, satellite system, radio system and other fields.

How are PCB high-frequency boards processed and produced? technological process:

NPTH's PTFE plate processing flow

Cutting - drilling - dry film - inspection - etching - corrosion inspection - solder resistance - characters - tin spraying - forming - testing - final inspection - packaging - shipping

Process flow of PTFE plate of PTH

Cutting - drilling - hole treatment (plasma treatment or sodium naphthalene activation treatment) - copper deposition - plate electricity - dry film - inspection - graphic electricity - etching - corrosion inspection - solder resistance - characters - tin spraying - forming - testing - final inspection - packaging - shipment

Difficulties in high-frequency board processing:

1. Copper sinking: the hole wall is not easy to be coated with copper

2. Control of line gap and sand hole of drawing, etching and line width

3. Green oil process: control of green oil adhesion and green oil foaming

4. Scratches on the board surface shall be strictly controlled in each process.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the advantages of PCB high-frequency boards and their production and processing methods.