PCB Engineer Teaches You How to Make PCB Quickly

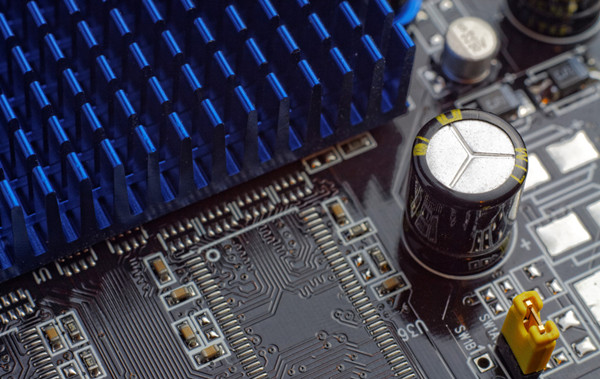

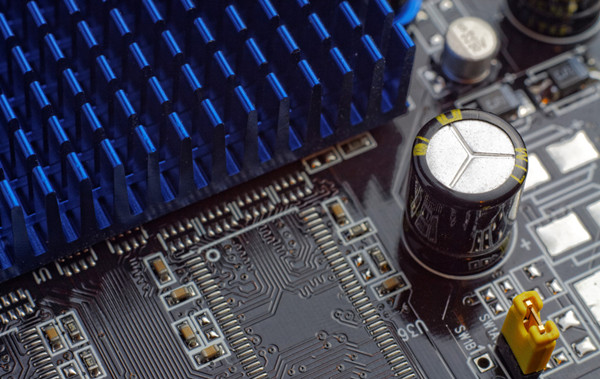

PCB production process, that is, PCB production process. Almost every kind of electronic equipment, from electronic watches and calculators to computers, communication electronic equipment and military weapon systems, as long as there are integrated circuits and other electronic components, printed boards are used for their electrical interconnection. In the research process of large-scale electronic products, the most basic success factor is the design, documentation and manufacturing of the product's printed board. The design and manufacturing quality of PCB directly affects the quality and cost of the whole product, and even leads to the success or failure of commercial competition.

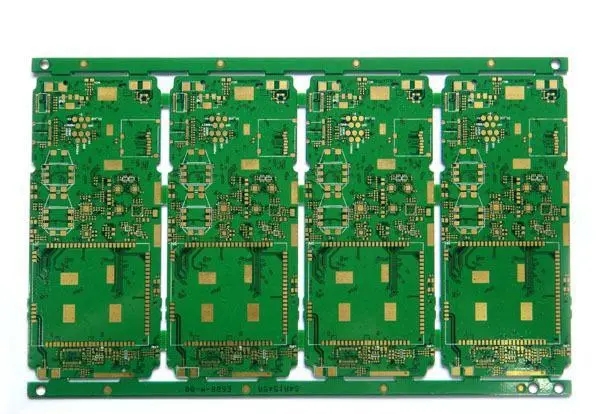

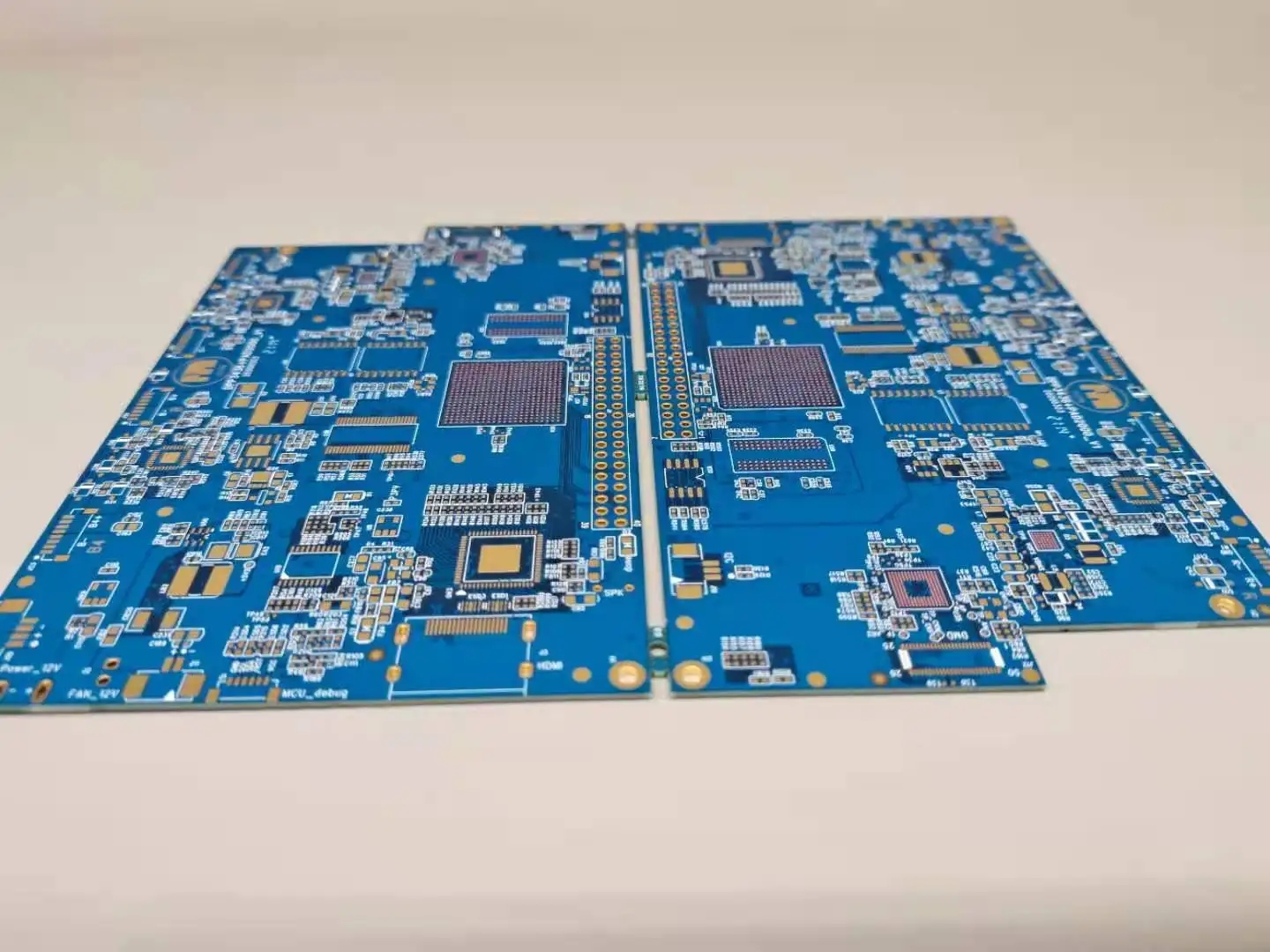

Printed boards have developed from single-layer to double-sided, multi-layer and flexible, and still maintain their own development trends. Due to the continuous development towards high precision, high density and high reliability, and the continuous reduction of volume, cost and performance, the printed circuit board will still maintain strong vitality in the future development project of electronic equipment. 3、 Marks of printed board technical level:

For double-sided and multilayer hole metallized printed boards, the mark of technical level of printed boards is that the double-sided metallized printed boards produced in large quantities can be marked by the number of wires that can be laid between two pads at the intersection of 2.50 or 2.54mm standard grids.

1> Mechanical carving

This method is to use the physical engraving method to separate the lead and pad on the PCB from the copper coating. Of course, if you don't have such expensive professional equipment, you can also use art knife to depict by yourself. It is still possible for some very simple circuits. In special cases, the PCB copper layer can also be carved by high-power laser, which is suitable for the production of some special substrate PCB, such as ceramic substrate PCB, aluminum substrate PCB, etc.

2> Chemical corrosion

The principle of this kind of method is similar to the traditional PCB production process. It covers the pads and leads that need to be retained on the copper coating surface of the PCB through exposure, thermal transfer, ink-jet printing, oil pen hand painting and other methods, and then uses the chemical corrosion method to remove the rest of the copper coating, so as to form a usable PCB.

Corrosion of circuit board by ferric chloride

Including:

·Exposure method: For PCB boards that need special pre coated photosensitive adhesive, use an ultraviolet lamp to complete the exposure. After that, the circuit board can be obtained through two steps of development and corrosion;

·Thermal transfer method: simply print the PCB circuit diagram on the thermal transfer paper through a laser printer, and then fix the toner on the PCB copper coating layer through a specific thermal transfer machine. After corrosion, the required circuit board can be obtained;

·Inkjet printing: it is an inkjet printer that needs to be specially modified [1], printing the circuit directly on the PCB;

·Paint with oil pen: The simplest way is to use an ordinary oil marker pen and paint with dexterity.

3> Paste circuit

Some leads are simple and can be pasted with copper foil tape through circuits with large current.

4> Conductive ink

This is to add some nano silver particles into the ink, so that the ink can quickly dry and conduct electricity, forming a conductive metal film. On this basis, the required circuit can be formed.

The advantage of the circuit formed in this way is that the required circuit can be formed on any object surface, but the width of the circuit is relatively large, and the resistance of the circuit is large, which is suitable for making some simple control signal circuits.

5> A castle in the air

To achieve the highest level of circuit, that is, circuit without circuit board. In fact, in the early circuit production, because of the large size of electronic components, the circuit was directly welded between the pins of components using leads. The current device ratio is relatively small. Under special circumstances, removing the circuit board can greatly reduce the size of the circuit.

Circuit board manufacturing, circuit board design and PCBA processing manufacturers will explain to you how to make PCB quickly