Knowledge of PCB proofing and how to distinguish the quality of ceramic substrate

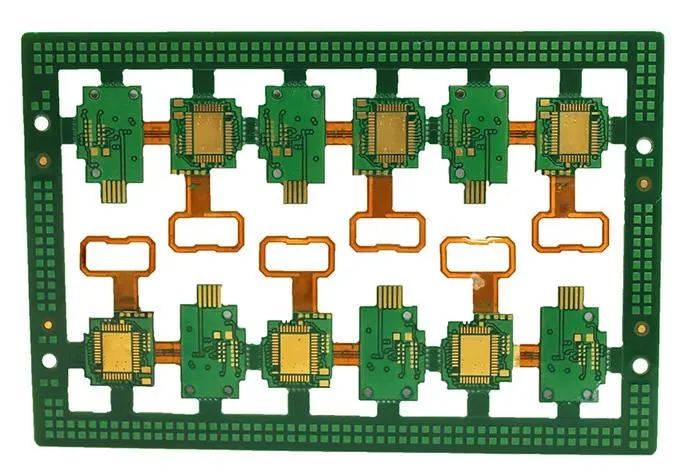

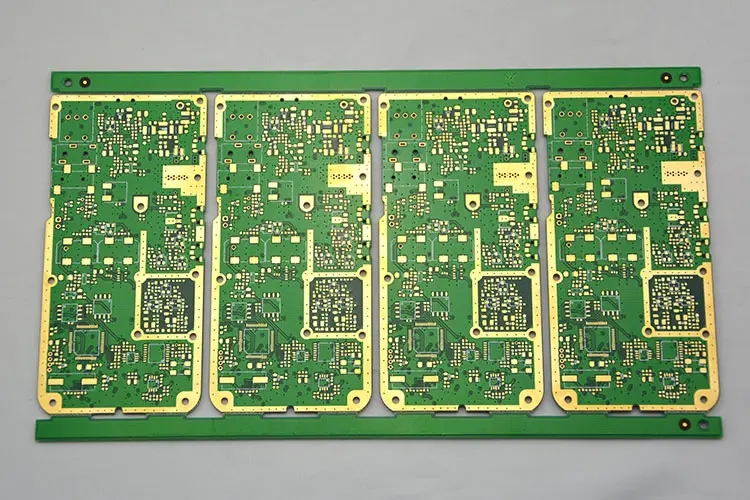

PCB proofing refers to the production of a small number of PCB templates for functional debugging before the start of mass production of PCB; After the function debugging is completed, the subsequent batch production can be carried out, which can avoid the production risk and reduce the loss caused by product errors.

For customers, what factors are most concerned about PCB proofing?

1. Speed

In PCB industry, time is a very important factor. Delivery time and quality are the hard strength of the factory, and are also the most favored by purchasing customers. Now PCB proofing factories generally provide urgent services, such as 12 hour and 24 hour urgent shipment; Usually, the normal delivery time of single and double sided boards is 2 days.

2. Quality

PCB proofing, quality must not be ignored. From raw materials, drawings, to production, testing, quality control, each link needs to be strictly controlled. Take ordinary double-sided plates for example. The plate materials generally include FR-4, aluminum substrate, CEM-1, etc. The plate thickness ranges from 0.4mm to 3.0m, and the copper thickness ranges from 0.5oz to 3.0oz. The difference of these materials results in great difference in quotation. At present, the manufacturers use imported plates as the better materials.

3. Price

With the development of the industry, the price of PCB proofing and small and medium-sized batch production is declining. Complete challenging tasks with challenging prices. This will be the price trend of PCB proofing.

So, what are the standards for measuring the quality of PCB proofing?

1. The copper skin is not easy to fall off under high temperature;

2. The line thickness, line spacing and line width of the line shall meet the design requirements to prevent heating, short circuit and open circuit of the line;

3. PCB board has no additional electromagnetic radiation;

4. During PCB proofing, high temperature, high humidity and other special environments are considered;

5. Copper surface is not easy to be oxidized;

6. Reasonable deformation error; The hole position of the circuit board and the deformation error of the circuit design shall be within the allowable range.

Combining the above six aspects to measure the printed circuit board, we can judge whether it is "excellent" or not. At present, there are tens of thousands of PCB proofing manufacturers in the market. It is recommended that users should be careful in the selection process and select manufacturers based on a certain understanding of PCB to prevent being cheated.

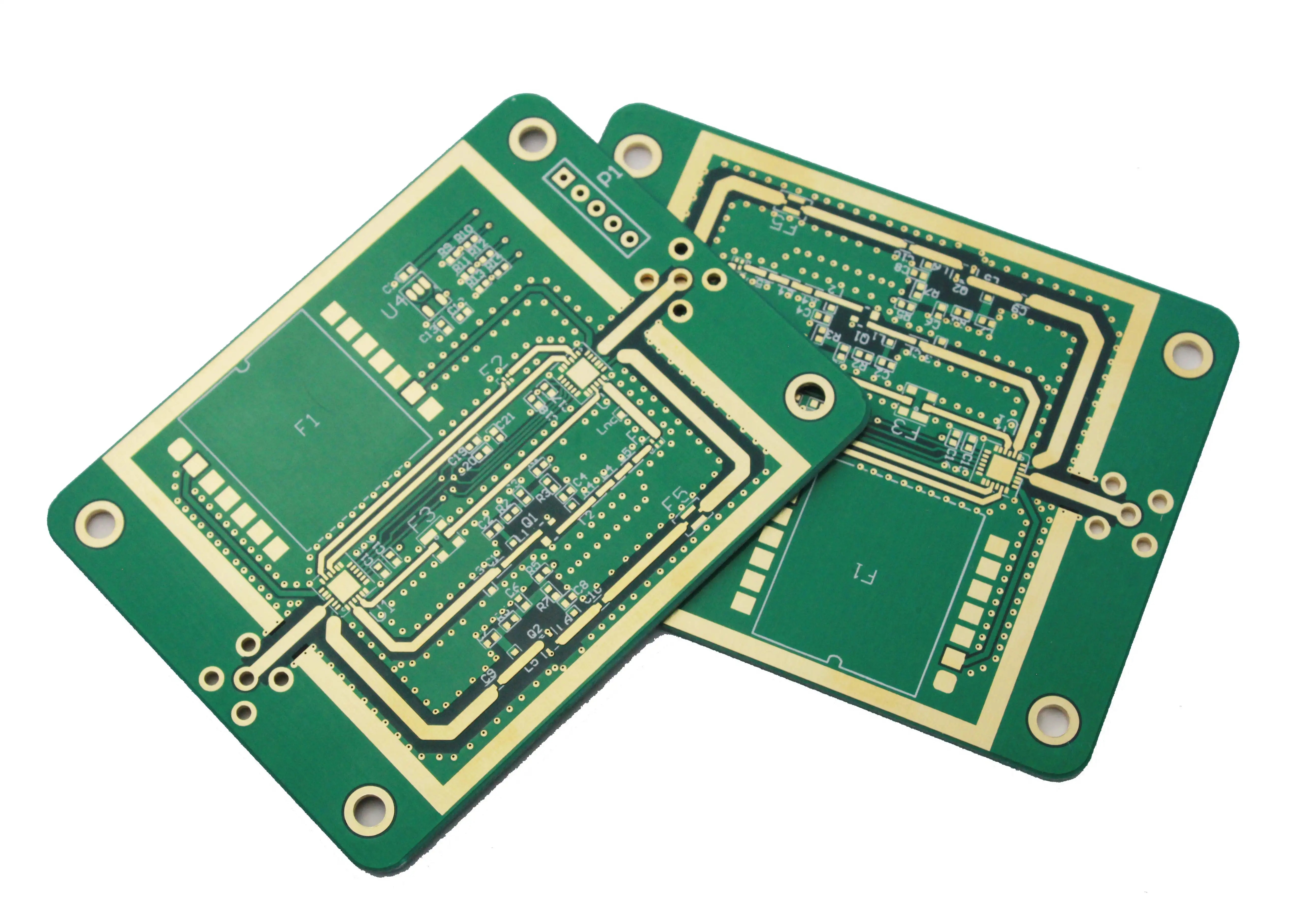

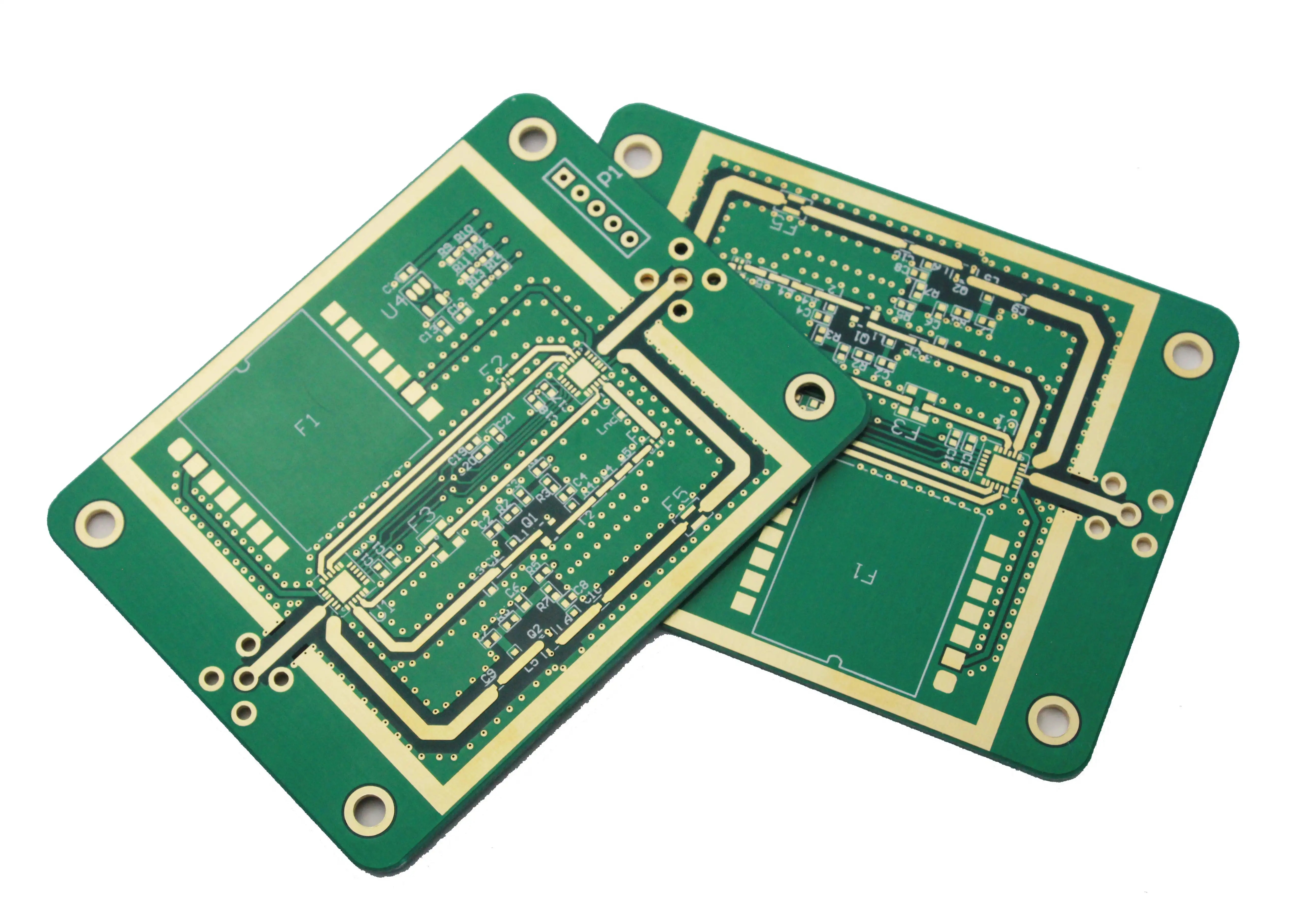

How to distinguish the quality of ceramic substrate?

Ceramic substrate refers to a special process plate that copper foil is directly bonded to the surface (single or double sides) of alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate under high temperature.

Ceramic substrate has become the basic material of high-power power electronic circuit structure technology and interconnection technology.

It is widely used in the manufacturing of electronic industry. It has become an important component in the manufacturing of electronic products due to its good thermal conductivity, high pressure resistance, chemical stability and many other advantages.

So, how to distinguish the quality of ceramic substrate?

Check the quality parameters of ceramic substrate. The ceramic substrate with guaranteed quality shall be made of substrate materials with stable chemical properties (high temperature resistance, strong acid and alkali resistance), high thermal conductivity and many good qualities. The parameter information in this regard can be obtained through consultation or by checking the specific product manufacturing instructions.

2. The ceramic substrate is of fine workmanship. High quality ceramic substrate requires strict requirements on the distance between electronic components, bonding tightness, etc. Of course, the high appearance flatness and flat edge of the plate can also reflect its processing quality.

3. Pass the trial. A major advantage of ceramic substrate is its good thermal conductivity. It can let the plate work for a period of time, then cut off the power supply to stop its work, test its temperature and the current flow speed of the whole circuit. If the temperature is too high, it indicates that its thermal conductivity is not good, and it is not a high-quality ceramic substrate.

4. Learn about the manufacturer information of ceramic substrate. The manufacturer of ceramic substrate is formal and has multiple qualifications, which often means that its production and manufacturing are through formal and strict production processes and requirements, and the selection of materials will also be guaranteed; Of course, we also need to know the corresponding brand reputation and user evaluation of ceramic substrate, which can directly reflect the quality of ceramic substrate to a certain extent. PCB manufacturing, PCB design and PCBA processing manufacturers explain the knowledge of PCB proofing and how to distinguish the quality of ceramic substrates