Rogers RO3006 High frequency circuit board material parameters

Today, the editor of the circuit board manufacturer will let you know the material parameters of Rogers RO3006 high-frequency circuit board

Printed circuit boards, also known as printed circuit boards, are providers of electrical connections for electronic components.

Printed circuit board is usually represented by "PCB", not "PCB".

PCB design is mainly layout design; The main advantage of using circuit board is to greatly reduce wiring and assembly errors, and improve the automation level and production labor rate.

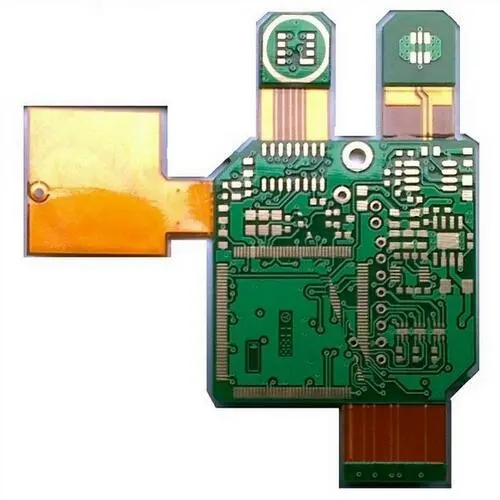

Printed circuit board can be divided into single panel, double panel, four layer board, six layer board and other multi-layer circuit boards according to the number of circuit board layers.

High frequency circuit board is a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as the frequency above 1GHz. Its physical performance, accuracy and technical parameters are very high, and are commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields. The high frequency circuit board comprises a core board with a hollow slot and a copper clad plate which is glued on the upper and lower surfaces of the core board by flowing glue. The upper opening and the lower opening edges of the hollow slot are provided with retaining edges.

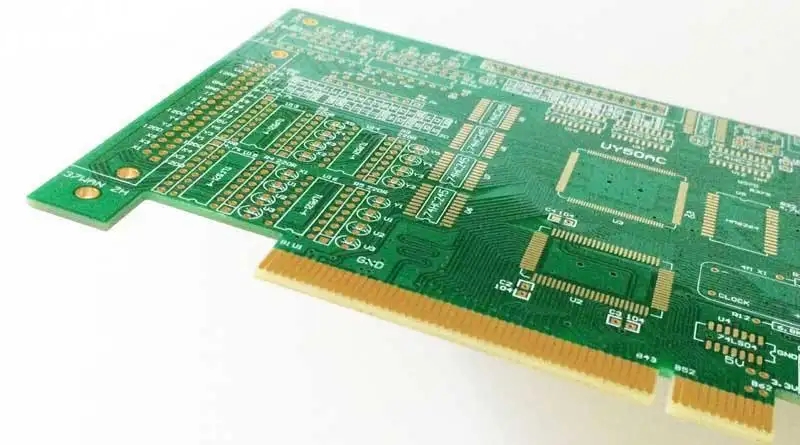

Rogers RO3006 series high-frequency circuit board materials are PTFE composite materials added with ceramic filler. The application of this material makes the dielectric constant of RO3006 series have extremely high temperature stability. When working at 10GHz and the temperature changes from - 50 ℃ to+150 ℃, the thermal stability coefficient of its dielectric constant (Z direction) can reach - 3ppm/℃. There will be no step change in the dielectric constant of PTFE glass at room temperature. At the same time, RO3006 also maintains high frequency stability of dielectric constant and can be used in a wide frequency range. Rogers RO3006 laminate also shows a very low dielectric loss of 0.0013 at 10GHz.

Also thanks to the application of this composite material, the thermal expansion coefficient of Rogers RO3006 PTFE ceramic material for high-frequency circuit board board in X and Y directions is 17ppm/℃, which is equivalent to the thermal expansion coefficient of copper, so that the typical value of the material due to etching shrinkage (baking after etching) is lower than 0.5mil/inch, showing excellent dimensional stability. Its thermal expansion coefficient in Z direction is 25ppm/℃, which can ensure the stability of electroplated through-hole even under harsh temperature environment.

With excellent dielectric constant temperature and frequency stability, as well as excellent mechanical stability, Rogers RO3006 PTFE ceramic makes RO3006 high-frequency circuit board suitable for commercial microwave and RF circuits, such as automotive radar, GPS satellite antenna, power amplifier and antenna of cellular communication system, live broadcast satellite, data link of wired system, remote meter reading and power supply backplane.

The RO3000 high-frequency circuit board family also includes RO3006 PTFE ceramics, RO3010 PTFE ceramics and RO3035 PTFE ceramics, which have different dielectric constants (ranging from 3.0 to 10.2), but have uniform mechanical stability, which can save developers from warping or reliability problems due to the use of materials with different dielectric constants in a layer when designing multilayer circuits.

PCB manufacturers, PCB designers and PCBA processors will explain the materials parameters of Rogers RO3006 high-frequency PCB.