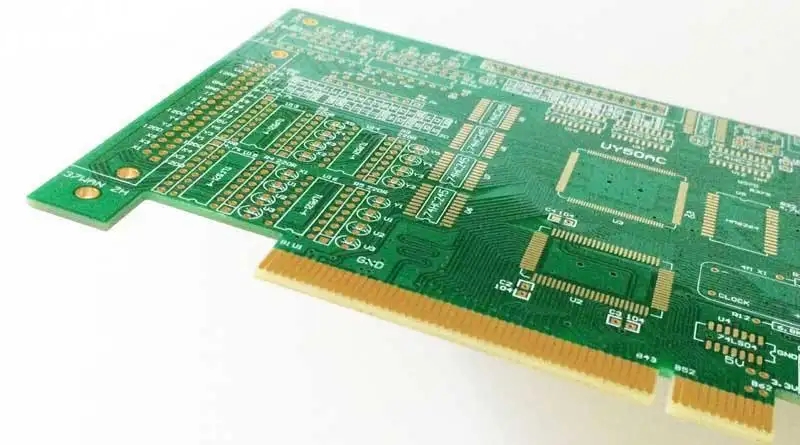

Circuit board manufacturer: high-frequency board multilayer mixed voltage PCB board

Circuit board manufacturer, circuit board design and PCBA processing manufacturer explain circuit board manufacturer: high-frequency board multilayer mixed voltage PCB board

High frequency multilayer hybrid PCB needs to use materials with different key characteristics than traditional multilayer PCB. The high-frequency plate mixing plate can be a mixture of FR4 and all domestic or imported high-frequency plates, or a mixture of high-frequency plates of different DKs. With the innovation of technology, hybrid structures are becoming more and more popular. This not only brings benefits, but also challenges that we need to better understand.

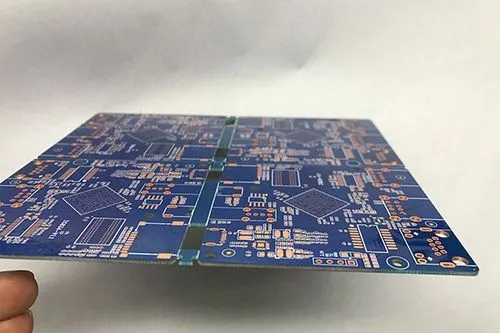

There are three main reasons for the use of high-frequency multilayer composite plates: cost, improved reliability and enhanced electrical performance. High frequency circuit board materials are much more expensive than FR4. Sometimes, the mixed voltage of FR4 and high-frequency circuit board can solve the cost problem. In many cases, some circuits of the high-frequency board multi-layer hybrid PCB have high requirements for electrical performance, while others have low requirements. In this case, FR4 will be used for parts with low electrical performance requirements, while more expensive high-frequency materials will be used for parts with high electrical performance requirements.

Another reason for using high-frequency multilayer hybrid PCB is that when the CTE value of PCB materials used is relatively high, the reliability can be improved. Some high-frequency PTFE materials have the characteristics of high CTE, which will cause reliability problems. When a low CTE FR4 material and a high CTE material are combined to form a high-frequency multilayer circuit board, composite CTE is acceptable. Some materials with different DKs are mixed to improve the electrical performance. In some combiner and filter applications, the use of mixed voltage of materials with different DK values will be beneficial to the improvement of electrical performance. The mixing of FR4 and high-frequency materials is becoming more and more common, because FR4 and most high-frequency circuit board materials have few compatibility problems. However, there are several problems in high-frequency circuit board manufacturing that deserve attention.

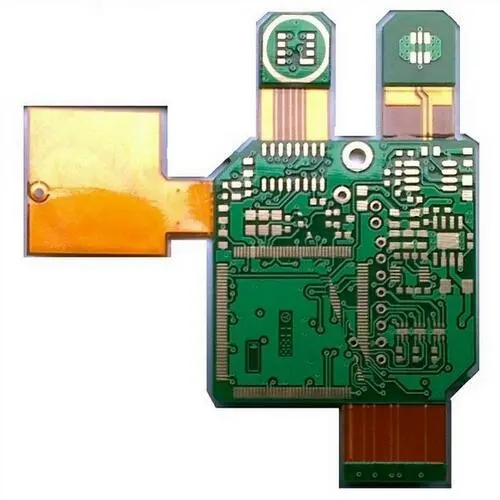

The use of high-frequency plates in hybrid compression structures will cause great differences in temperature due to special processes. The high-frequency materials of the basic PTFE will bring many problems in the manufacturing process of the circuit, because special preparation requirements for drilling and through hole electroplating PTH are required. The plates based on hydrocarbon resin are easy to process, and the same circuit manufacturing process as the standard FR4 is used.

The mixed pressing of FR4 and high-frequency plates based on hydrocarbon resin materials basically has no manufacturing problem. The main problems are drilling and pressing. To establish a correct bit feed and drilling speed, design experience is required. The pressing of FR4PP sheets is a problem because it requires a ramp rate (temperature rise rate) that is very different from that of hydrocarbon high-frequency materials. In order to have more reliable mixing, several options are worth considering. First, use the PP sheet of high-frequency material to replace the P sheet of FR4, and use the correct pressing cycle. The P sheet of high-frequency material is usually not as expensive as the copper clad laminate. In addition, the bonding layer of the same material is more conducive to simpler pressing cycle. When the FR4P sheet cannot be replaced, it must be pressed in order: first press the P sheet of FR4, and then press the P sheet of high-frequency material.

The mixing of FR4 and PTFE materials is more challenging, but there are exceptions. There are several different types of PTFE CCL, some of which are easier to machine than others. Even though PTFE copper clad laminate with ceramic filler has fewer processing problems than PTFE, drilling, PTH through-hole electroplating preparation and dimensional stability also need to be considered.

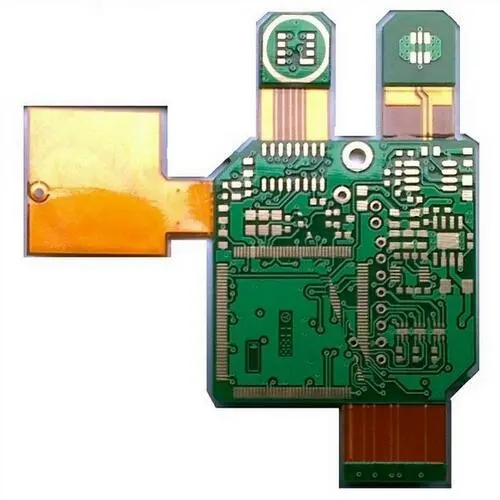

The biggest problem of PTH drilling is that PTFE material is relatively soft, while FR4 is relatively hard. When drilling PTH and drilling tools, there will be some soft materials in the hole that extend to cover the hole wall of PTH. This will cause serious reliability problems. Generally, the bit and drilling speed must be determined by experienced engineers, and the service life of the bit is also worth studying. In many cases, flapdefect does not appear in the early use of the drill bit. Therefore, a better understanding of the life of the drill bit is very important to reduce such concerns. PTH preparation must be aimed at the following two types of materials: electroplating through-hole process plasma cycle may require two different cycles or one cycle, but multiple stages. In the first plasma cycle, FR4 materials should be treated first, and then PTFE materials should be treated in the second cycle. Generally, CF4-N2-O2 gas is used for FR4 and He or NH gas is used for PTFE in the plasma treatment process. For PTFE materials, to improve the wettability of the via wall, a better suggestion is to use Helium (He) helium. If wetprocessing is used when preparing PTH, permangate FR4 first, and then sodiumnaphthalene PTFE materials.

For high frequency boards made of FR4 and PTFE, multi-layer hybrid PCB boards, dimensional stability or scaling is bound to be a problem. By minimizing the mechanical pressure acting on PTFE materials, the occurrence of problems can be reduced. For the next process of preparing copper foil, chemical cleaning process will be a better method. The thicker the PTFE copper clad plate is, the less dimensional stability problems will occur. Similarly, PTFE substrate reinforced with glass fiber will be more stable in size.

In general, there is basically no compatibility problem in the manufacture of FR4 and hybrid PCB made of high-frequency circuit materials. However, several concerns about PCB manufacturing are still worth noting. In order to have better results, it is recommended that high-frequency circuit board manufacturers communicate, exchange and discuss with material manufacturers first when high-frequency multilayer hybrid PCB boards are needed. Circuit board manufacturers, circuit board designers and PCBA processors will explain to you the circuit board manufacturers: high-frequency boards, multi-layer hybrid PCBs.