PCB high-frequency board resistance welding process often encounters problems

PCB manufacturers, PCB designers and PCBA manufacturers explain some problems often encountered in the solder resistance process of PCB high-frequency boards

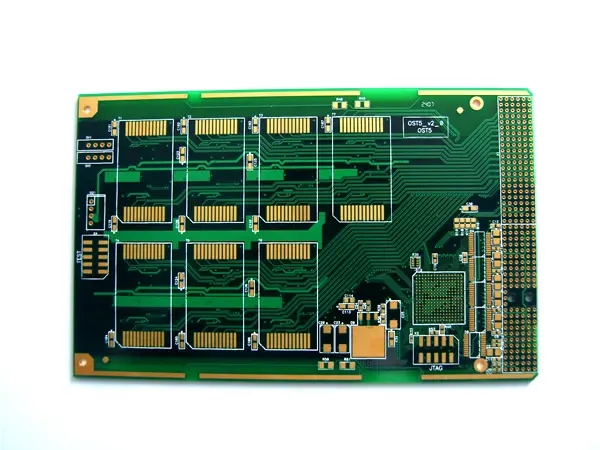

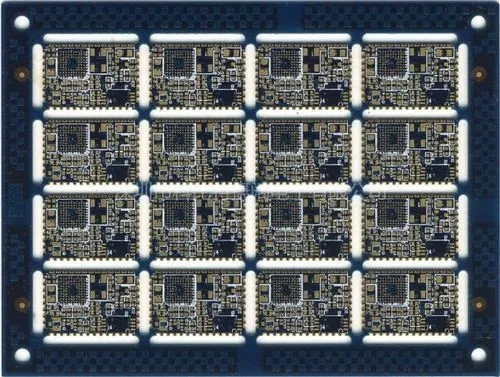

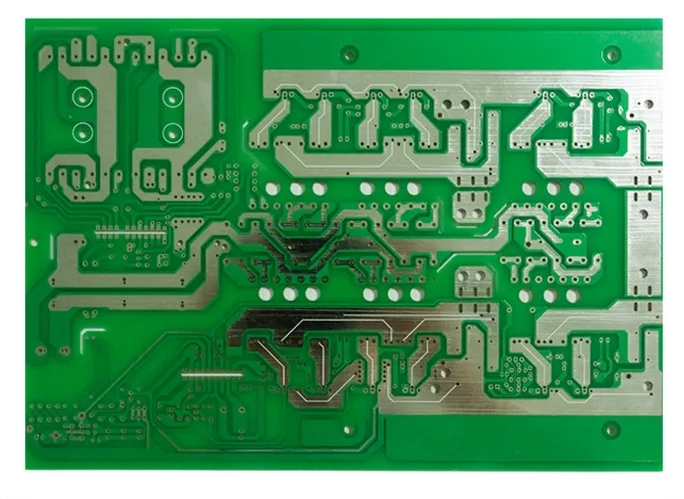

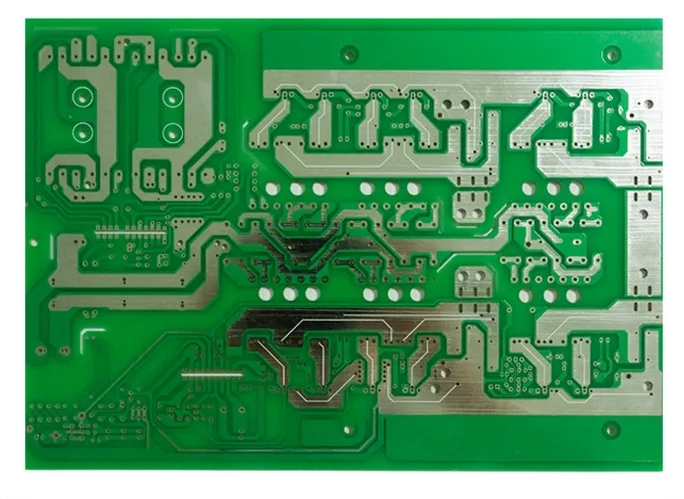

Everyone in the PCB high-frequency board design industry knows that solder mask is a layer of ink printed on the surface of the PCB high-frequency board. It not only plays the role of insulation, but also plays the role of protecting the copper surface, and also plays a beautiful role. It is like a piece of clothing worn outside the PCB high-frequency board. Therefore, any flaw in it is very easy to be found, so solder mask is also the process most likely to cause customer complaints in all processes. In the resistance welding process of PCB high-frequency boards, you may also encounter a variety of quality problems. The following sections summarize the countermeasures for some common problems, hoping to give you inspiration and help. Common:

Problem: PCB high-frequency board penetration and blurring

Cause 1: Ink viscosity is too low.

Improvement measures: increase the concentration without adding thinner.

Cause 2: High frequency PCB screen pressure is too high.

Improvement measures: reduce the pressure.

Cause 3: The rubber scraper is poor.

Improvement measures: replace or change the angle of the squeegee screen.

Cause 4: The distance between the high-frequency PCB screen and the printed surface is too large or too small.

Improvement measures: adjust the spacing.

Cause 5: The tension of the screen on the high-frequency PCB board decreases

Improvement measures: Make new screen version.

Problem: Viscous film

Cause 1: PCB high-frequency board ink is not baked dry

Improvement measures: check the ink dryness

Cause 2: Too strong vacuum pumping

Improvement measures: check the vacuum pumping system (air guide strip may not be added)

Problem: Poor exposure

Cause 1: Poor vacuum pumping

Improvement measures: check the vacuum pumping system

Cause 2: Improper exposure energy

Improvement measures: adjust appropriate exposure energy

Cause 3: The temperature of the exposure machine is too high

Improvement measures: check the temperature of the exposure machine (lower than 26 ℃)

Problem: The ink won't dry

Cause 1: Poor ventilation of the oven

Improvement measures: check the air exhaust condition of the oven

Cause 2: Insufficient oven temperature

Improvement measures: determine whether the actual temperature of the oven reaches the required temperature of the product

Cause 3: Thinner is not enough

Improvement measures: add thinner and fully dilute

Cause 4: Thinner dries too slowly

Improvement measures: use the matching thinner [please use the company's matching thinner]

Cause 5: The ink is too thick

Improvement measures: appropriately adjust the ink thickness

Problem: There are white dots in the printing

Cause 1: There are white dots in the printing

Improvement measures: The thinner does not match. Use the matching thinner [please use the company's matching thinner]

Cause 2: The sealing tape is dissolved

Improvement measures: use white paper to seal the net

Problem: Excessive development (corrosion measurement)

Cause 1: Too high concentration and temperature of liquid medicine

Improvement measures: reduce the concentration and temperature of liquid medicine

Cause 2: Development time is too long

Improvement measures: shorten the development time

Cause 3: Insufficient exposure energy

Improvement measures: increase exposure energy

Cause 4: Excessive developing water pressure

Improvement measures: reduce the pressure of developing water

Cause 5: uneven mixing of ink

Improvement measures: Stir the ink evenly before printing

Cause 6: PCB high-frequency board ink is not dried

Improvement measures: adjust the baking parameters, see the problem [Ink does not dry]

Problem: Green Oil Bridge is broken

Cause 1: Insufficient exposure energy

Improvement measures: increase exposure energy

Cause 2: PCB high-frequency boards were not handled properly

Improvement measures: check the processing procedure

Cause 3: Too much developing and washing pressure

Improvement measures: check the developing and washing pressure

Problem: Unclean development

Cause 1: PCB high-frequency board is placed for too long after printing

Improvement measures: control the storage time within 24 hours

Cause 2: Ink runs out before development

Improvement measures: work in the darkroom before development (fluorescent lamps are wrapped in yellow paper)

Cause 3: Insufficient developer solution

Improvement measures: if the temperature is not enough, check the concentration and temperature of liquid medicine

Cause 4: Development time is too short

Improvement measures: extend the development time

Cause 5: High exposure energy

Improvement measures: adjust exposure energy

Cause 6: Excessive baking of ink

Improvement measures: adjust baking parameters to prevent baking

Cause 7: uneven mixing of ink

Improvement measures: Stir the ink evenly before printing

Cause 8: Diluent mismatch

Improvement measures: use the matching thinner [please use the company's matching thinner]

Problem: Poor tin coating

Cause 1: Unclean development

Improvement measures: several factors to improve the development uncleanness

Cause 2: Post baking solvent pollution

Improvement measures: increase oven exhaust or machine cleaning before tin spraying

Problem: post drying and exploding oil

Cause 1: No segmental baking

Improvement measures: baking in sections

Cause 2: The viscosity of the plug hole ink is not enough

Improvement measures: adjust the ink viscosity of the plug hole

Problem: blistering on tin

Cause 1: Overdevelopment

Improvement measures: improve the development parameters, see the problem [Excessive development]

Cause 2: The pretreatment of the plate is not good, and the surface is greasy. Dust

Improvement measures: do a good job in the pretreatment of plates and keep the surface clean

Cause 3: Insufficient exposure energy

Improvement measures: check the exposure energy to ensure it meets the requirements for ink use

Cause 4: Abnormal flux

Improvement measures: adjust the flux

Cause 5: Insufficient post baking

Improvement measures: post inspection baking process

Problem: Ink discoloration

Cause 1: Insufficient ink thickness

Improvement measures: increase the ink thickness

Cause 2: substrate oxidation

Improvement measures: pre inspection processing procedure

Cause 3: The post baking temperature is too high

Improvement measures: too long to check the baking parameters

Problem: Matte ink

Cause 1: Diluent mismatch

Improvement measures: use the matching thinner [please use the company's matching thinner]

Cause 2: Low exposure energy

Improvement measures: increase exposure energy

Cause 3: Excessive development of PCB high-frequency board

Improvement measures: improve the development parameters, see the problem [Excessive development]

Problem: blocking

Cause 1: Too fast drying.

Improvement measures: add slow drying agent.

Reason 2: The printing speed is too slow.

Improvement measures: increase the speed and slow the drying agent.

Cause 3: The ink viscosity is too high.

Improvement measures: add ink lubricant or extra slow drying agent.

Cause 4: Diluent is not suitable.

Improvement measures: use the specified thinner.

Problem: The ink adhesion is not strong

Cause 1: The model of PCB high-frequency board ink is not suitable.

Improvement measures: change to appropriate ink.

Cause 2: The model of PCB high-frequency board ink is not suitable.

Improvement measures: change to appropriate ink.

Cause 3: The drying time and temperature are incorrect and the exhaust air volume during drying is too small.

Improvement measures: use correct temperature and time, and increase exhaust air volume.

Cause 4: The dosage of additives is inappropriate or incorrect.

Improvement measures: adjust the dosage or use other additives.

Cause 5: Excessive humidity.

Improvement measures: improve the air dryness.

PCB manufacturers, PCB designers and PCBA manufacturers explain some problems often encountered in the resistance welding process of PCB high-frequency boards.