What materials and functions do we need to choose to make high-frequency boards

PCB manufacturers, PCB designers and PCBA manufacturers will explain to you what materials and functions we need to select to make high-frequency boards

What kind of materials do we need to choose to make high-frequency boards

Generally, FR-4 glass fiber plate can be used, but high-frequency materials such as semi ceramic materials should be used when the frequency is about 1-5G. ROGERS4350 series, 4003 series and 5880 series are commonly used.

If the frequency is higher than 5 G, it is better to use PTFE material, that is, polytetrafluoroethylene (PTFE). This material has good high-frequency performance, but the processing technology is limited, such as the surface technology that cannot be used for hot air leveling.

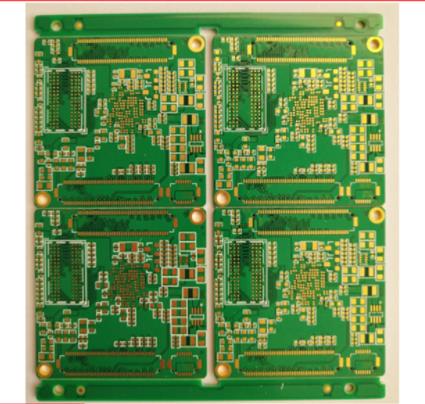

Example of high-frequency plate selection

I. 1.9GHz RF transceiver

Among them, the power amplifier adopts high-frequency board PTFE board and double-sided circuit board; RF transceiver adopts high-frequency board PTFE board and four layer PCB board. Large area floor covering and functional module shielding cover are adopted for isolation.

II. Selection of 2.4GHz spread spectrum digital microwave relay board

Its structure includes 2M digital interface, 20M spread spectrum despreading, 70M intermediate frequency modulation and demodulation board. We use FR4 board, four layers of PCB board, and large area of flooring. The high-frequency analog part of the power supply is isolated from the digital part by an inductive choke.

The 2.4GHz RF transceiver adopts F4 double-sided circuit board. The transceiver is shielded by metal boxes and filtered at the power inlet.

III. 70MHz IF transceiver

FR4 glass fiber board and four layer PCB board are adopted. A large area of floor is paved, and the functional module isolation belt is isolated by a series of vias.

IV. 30W power amplifier

RO4350 sheet and double-sided circuit board are used. A large area of ground is paved, the spacing constraint is greater than or equal to 50 ohm line width, the metal box is used for shielding, and the power input is filtered.

V. 140MHz IF transceiver

The top layer is made of 0.3mm S1139 plate, which is used for large-area floor paving and via hole isolation.

VI. 2000 MHz Microwave Frequency Source

S1139 sheet with a thickness of 0.8mm and double-sided circuit board shall be used.

Devices in the wireless field involve a wide range of applications and are more complex, especially in the current wireless communication market, where competition is fierce. The price and time to market of products are increasingly becoming the focus of competition. Therefore, electronic engineers can not only consider the progressiveness of technology in PCB design, but must compromise from many aspects, balance the key factors such as progressiveness of technology, price advantage and shortening the time to market of products, so as to improve the competitiveness of products.

What are the functions of high-frequency circuit board

When electronic equipment and products need special signal requirements, high-frequency circuit boards can be used for manufacturing. Its working environment is 500MHz-2GHz. Therefore, high-frequency PCB/high-speed PCB/high-frequency microwave RF board is an ideal choice for high-end applications. Today, the complexity of electronic devices is increasing rapidly. Therefore, we need high-frequency PCB board to provide faster signal flow rate.

In PCB industry, people often confuse high-speed PCB layout with high-frequency PCB layout. They do so because they believe that the two terms are the same. However, this is not the case because the two terms have completely different meanings.

High speed PCB design involves high-frequency PCB that must allow data transmission at a very high rate. Therefore, it refers to the time domain. High frequency PCB design involves PCB circuit boards that process high frequency and short wavelength signals. Therefore, it refers to the electromagnetic wave of incoming and outgoing signals. High frequency circuit board has the following functions:

1. High frequency circuit board usually has low dielectric constant (about 2.40) and strict tolerance.

2. These have small hygroscopicity. Therefore, they have excellent heat and moisture resistance.

3. High frequency circuit board has ideal performance under reflux condition. Therefore, they are conducive to industrial applications.

4. High frequency circuit board has excellent dimensional stability. Therefore, it is very suitable for applications involving extreme environmental conditions.

5. High frequency circuit boards have a thermally stable structure because their Z-axis CTE is relatively low. Therefore, low CAF resistance and low Z-CTE result in long service life of these PCBs.

6. The dissipation coefficient of high-frequency circuit board is small. Therefore, their tangent loss is low. Therefore, it allows faster signal propagation and low signal distortion. Therefore, they are suitable for high-frequency PCB/high-speed PCB/high-frequency microwave RF board applications that require high reliability. PCB manufacturers, PCB designers and PCBA manufacturers will explain to you what materials and functions we need to choose to make high-frequency boards.