The difference and relationship between RF circuit board and high-frequency microwave board

PCB manufacturers, PCB designers and PCBA manufacturers explain the differences and connections between RF circuit boards and high-frequency microwave boards

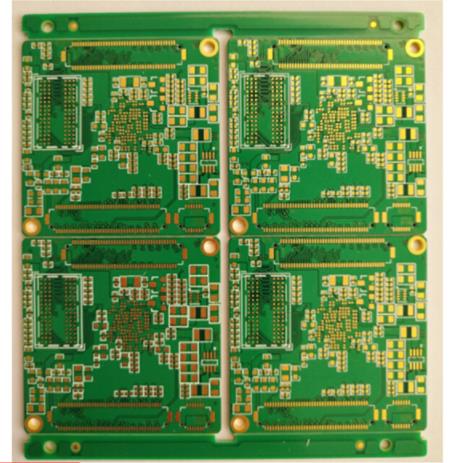

High frequency circuit board is a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as the frequency above 1GHz. Its physical performance, accuracy and technical parameters are very high, and are commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields.

Generally speaking, in PCB industry, RF PCB is considered as any high-frequency PCB working above 100MHz. In the RF category, any higher than 2 ghz is a high-frequency microwave plate. The main difference between RF circuit board and high-frequency microwave board is their working frequency. Microwave circuit board is classified as any RF circuit board that operates above 2GHz.

RF circuit boards and high-frequency microwave boards are used for communication signals in any application that requires receiving and transmitting wireless signals. For example, some common applications are mobile phones and radar devices, car collision avoidance systems and radio systems.

Compared with the traditional PCB layout, the design of RF PCB and HF microwave PCB is particularly difficult. This is due to possible problems when receiving or sending radio signals. Some of the main problems are noise sensitivity and tighter impedance tolerances. Compared with traditional circuit boards, radio and microwave signals are very sensitive to noise, and the requirements for PCB impedance tolerance are much higher. The best way to solve these problems is to use ground planning and generous bending radius on the impedance controlled trajectory. These solutions will ultimately enable the best performance of HF circuit boards/RF PCB/HF microwave boards.

Microwave RF boards and high-frequency microwave boards have many different applications, including wireless technology, smart phones, sensors, robots and security. With the emergence of new technologies that push the limits of electronic technology, the demand for RF circuit boards is rising. It also means that the PCB design and production process of RF circuit board will be very complex. Here are some special points to pay attention to:

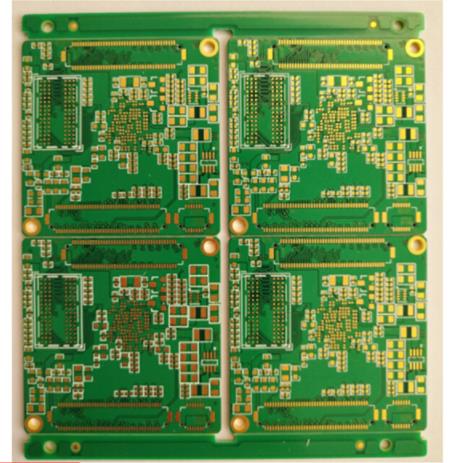

In non RF applications, some constants, such as dielectric constant, can be regarded as a single value, but they become more dynamic in the strong frequency range of RF.

2. Functional spacing will also play an important role, because RF boards are easy to interact with adjacent features in unexpected ways.

3. Selecting the right materials based on the target application and budget is critical because most of the remaining challenges will result from this choice.

4. Manage the heat in the PCB board to ensure that it can withstand considerable thermal stress. PCB components are critical. In the drilling stage, the thermal properties of PCB materials play a crucial role in the layered arrangement of multilayer stacks.

It is essential to find a capable manufacturer of high-frequency microwave RF boards to ensure that the boards are manufactured in accordance with high quality standards and on time. PCB manufacturers, PCB designers and PCBA manufacturers explain the differences and connections between RF PCB and high-frequency microwave PCB.