PCB manufacturer: overview of single-sided FPC manufacturing process

Circuit board manufacturer, circuit board design, PCBA manufacturer will explain to you: circuit board manufacturer: overview of single-sided FPC manufacturing process

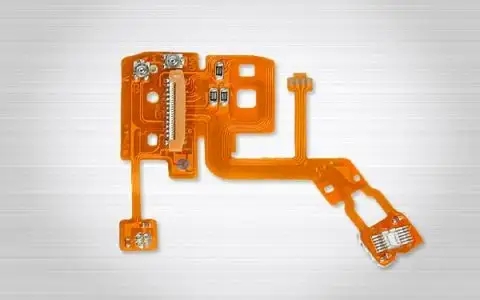

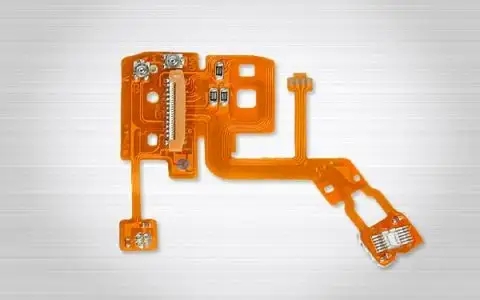

Flexible Printed Circuit Board (FPC) is referred to as "flexible Board", commonly known as FPC in the industry. It is a Flexible insulating substrate (mainly polyimide or polyester film) The printed circuit board has many advantages that the hard printed circuit board does not have. For example, it can bend, wind and fold freely. The volume of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products.

The flexible board has a variety of forms, and single-sided FPC is a relatively simple structure. Although it is relatively simple, it must also have the corresponding process materials and processing procedures.

High quality flexible circuit board manufacturing is based on complete, effective, accurate, small change in physical parameters, and imaging of polyester substrate. The imaging quality of accurate proportion is based on the control effectiveness of highly reliable process flow. It is also applicable to the requirements of the original drawing of resistance welding and silk screen printing.

In conclusion, the flexible board for manufacturing high-density interconnection structure, whether single side. Double sided or multi-layer and combination of soft and hard double-sided or multi-layer, the technical key may emerge in the actual production, but as long as the process characteristics are mastered and the key to production is fully understood, it is possible to obtain a perfect solution through practice. In order to meet the needs of the rapid development of HDI flexible board manufacturing technology and the rapid growth of HDI, material manufacturers, substrate manufacturers and instrument providers must constantly explore, develop and develop new materials, new process equipment and new testing methods and instruments to constantly meet the needs of various electronic products.

FPC single panel is the most commonly used FPC type. The production is carried out in two ways in the FPC single panel production process, namely, continuous roller type and single chip intermittent type. For roll forming processing during continuous roll production, this method has a large investment in equipment and tooling, but it is suitable for mass production and can greatly reduce manufacturing costs.

The single chip intermittent type is to cut the copper clad foil substrate into the required single pieces and process them according to the process flow sequence. There are discontinuities between processes, but many of the process methods used are the same. PCB manufacturers, PCB designers and PCBA processors will explain to you: PCB manufacturers: overview of single-sided FPC manufacturing process.