Performance comparison of the most commonly used rigid CCL for circuit boards

PCB manufacturers, PCB designers and PCBA manufacturers explain the performance comparison of the most commonly used rigid CCL for PCB

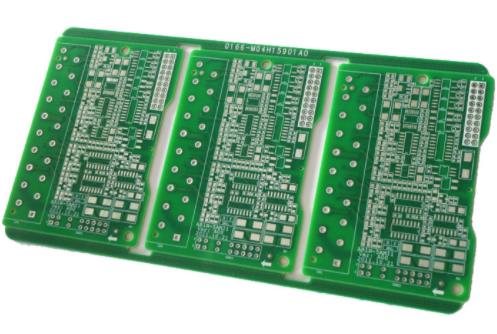

In PCB manufacturing, the rigid copper clad laminate commonly used includes three types of copper clad laminate products composed of different resins and different reinforcement materials. Paper based phenolic CCL; Glass fiber cloth based epoxy type; Composite epoxy type CCL.

1. Paper based copper clad plate

The most typical varieties and models of paper-based CCL are FR-1 (flame retardant) and XPC (non flame retardant). In addition, FR-2 (flame retardant paper-based phenolic CCL) and FR-3 (flame retardant paper-based epoxy CCL) have slightly higher electrical and mechanical properties than FR-1 and XPC. The overall performance of paper-based CCL is characterized by its low cost, low price, low relative density, and punching processing. However, its working temperature is low, and its heat resistance, moisture resistance and mechanical properties are lower than those of glass fiber cloth based epoxy CCL. The manufacturers of complete machine electronic products in Asia mostly use FR-1 or XPC type CCL products to manufacture PCBs. In Europe and the United States, customers of complete electronic products mostly use FR-2 and FR-3 CCL products to manufacture PCBs. Paper based copper clad laminate is mostly used in the manufacture of single panel. Due to the development of paper-based phenolic CCL products for silver paste through holes in Japan, it is popular to use this board to make double-sided boards in Japan. However, the adoption rate of this class is still low in mainland China.

2. Glass fiber cloth based epoxy copper clad plate

The most typical types of glass fiber cloth based epoxy copper clad laminate are FR-4 (flame retardant) and G-10 (non flame retardant). Among them, FR-4 CCL is by far the most widely used CCL variety in PCB manufacturing. In addition, FR-5 (flame retardant) and G-11 (non flame retardant) have better heat resistance than FR-4. The mechanical properties, dimensional stability, impact resistance and moisture resistance of glass fiber cloth based epoxy CCL are higher than those of paper based phenolic CCL. Its electrical performance is excellent, working temperature is high, and its performance is less affected by the environment. In terms of processability, glass fiber cloth based epoxy CCL has greater advantages than other resins (such as PI/BT/CE/PTFE/PPE). In recent years, a variety of glass fiber cloth based epoxy copper clad laminate (FR-4 CCL) has been developed according to the needs of the market, forming a series of products. Most of these FR-4 CCL varieties improve some of their properties by modifying the epoxy resin used. For example: FR-4 CCL with low medium constant, FR-4 CCL with high glass transition temperature, FR-4 CCL with low thermal expansion coefficient, FR-4 CCL with high metal ion mobility resistance, FR-4 CCL with high CTI, FR-4 CCL with UV shielding, FR-4 CCL with high elasticity (applicable to IC packaging carrier with chip inversion installation), halogen-free FR-4 CCL, thin FR-4 CCL and other products. In addition to being used in double-sided PCB, glass fiber cloth based epoxy CCL is also used as inner core thin copper clad plate (generally less than 0.8mm thick).

3. Composite epoxy copper clad plate

The composite epoxy type copper clad laminate mainly refers to the copper clad laminate composed of two different reinforcing materials, the surface layer and the core layer of the insulating substrate. In the composite epoxy type CCL, CEM-1 and CEM-3 are the most common. The mechanical properties and manufacturing costs of the composite based CCL are between those of paper based phenolic type CCL and glass fiber cloth based epoxy type CCL. The utility model can be used for punching processing, and is also suitable for mechanical drilling processing. Some CEM-3 CCL products are superior to common FR-4 CCL products in terms of CTI resistance, dimensional accuracy, dimensional stability, etc. The use of CEM-1 CCL and CEM-3 CCL to replace FR-4 CCL to manufacture double-sided PCB has been widely used in Japan, Europe, America and other countries and regions. In recent years, some foreign PCB manufacturers began to use the thin CEM-3 CCL as the inner core thin copper clad laminate of the multilayer board in the development of products in order to pursue cost and thin board. Even the semi cured sheet of CEM-3 is used, and the thin multilayer board is made entirely of CEM-3 substrate. Recently, it was also found that some Taiwanese PCB enterprises in the mainland of China have begun to produce and process thin CEM-3 CCL, which is mainly used as the inner core thin copper clad laminate of multilayer boards. PCB manufacturers, PCB designers, and PCBA manufacturers will explain the performance comparison of the most commonly used rigid CCL for PCB.