Overview of PCB chemical copper deposition (using formaldehyde as reducing agent)

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the overview of PCB chemical copper deposition (using formaldehyde as reducing agent)

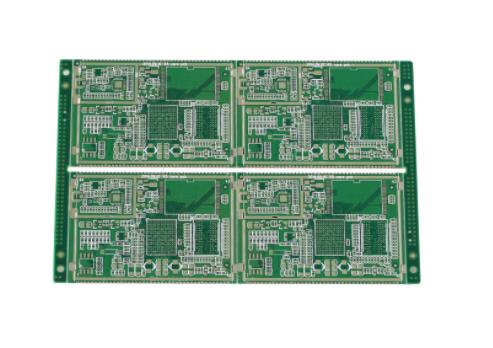

The interconnection of conductive images between layers of double-sided boards and multilayer boards is realized by hole metallization technology. Hole metallization refers to the process of coating a layer of conductive metal on the insulated hole wall of a printed board with conductive images insulated from each other by electroless plating and electroplating after drilling to make it interconnected. Double sided copper clad laminate and multilayer laminate, after drilling, the inner wall of the hole is non-conductive, that is, the conductive images between layers are not interconnected. After electroless copper plating, a conductive electroless copper layer is coated on the insulated hole wall, Then, the copper layer is thickened by electroplating copper to achieve the required thickness (generally 25 UM). From this point of view, the hole metallization of PCB is realized by two processes: electroless copper plating and copper electroplating.

Electroless plating refers to the process in which a metal replaces another metal in the solution to form a metal coating. It is a self catalyzed oxidation reduction reaction. It does not depend on whether the object to be plated is a metal. It completely uses a controllable method to initiate chemical reaction to deposit metal from the solution, and then uses this new ecological active metal atom as the catalytic core to continue to catalyze the subsequent metal reduction reaction until the deposition can reach the thickness.

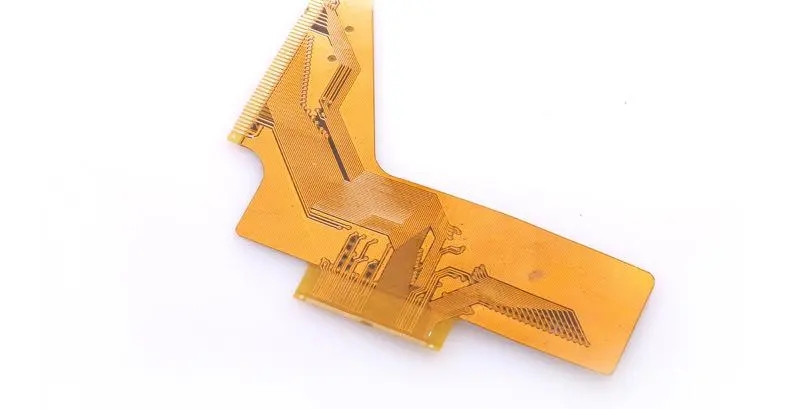

In order to obtain a good copper deposit, it is necessary to understand the process characteristics of electroless copper plating, which can be easily controlled effectively. It is not limited by the properties of the substrate, and can be used on both metal and non-metal surfaces; It is not limited by the surface shape of the object to be plated. No matter the groove, cavity, deep hole, blind hole, etc., any part that can contact with the solution can get a uniform coating. No additional current is required. The equipment is relatively simple and has a wide range of applications.

It is well known that the combination of electroless copper plating and non-metallic matrix is mechanical. Once thermal shock or temperature change is received, due to the large difference in thermal expansion coefficient between the coating and non-metallic matrix, thermal stress will cause separation of the coating. Therefore, each step in the process must be strictly controlled to obtain a reliable conductive layer. To this end, the following points should be strictly done:

(1) Strict pretreatment

For electroless plating on the surface of non-metallic materials, the treatment before plating includes two aspects. One is the surface cleaning treatment, which is used to remove organic or inorganic contaminants such as oil stains on the substrate surface, so that the plating solution can reliably contact the non-conductive surface; The other is surface modification, which is used to improve the wettability of the chemical plating solution to the substrate material, so that the coating can be firmly and tightly combined with the non-conductive surface. This is the function of modern electroless plating pretreatment formula. Therefore, correct formulation selection and strict operation and maintenance are two basic control points for quality control of pretreatment.

(2) Strict process condition control

According to the characteristics of self catalytic oxidation reduction electroless plating process, the operating process conditions must be strictly controlled to maintain chemical balance, otherwise two extremely unfavorable conditions will occur, namely, the plating solution is too stable, the deposition rate is too slow, and even the "cavities" with incomplete coating coverage will appear; The plating solution is too close to the reaction point, and after the plating piece is prohibited, the reaction is too violent, the deposit layer structure is loose, and the coating performance is poor, which can not meet the technical requirements of PCB hole metallization, and even lead to unnecessary consumption and spontaneous decomposition failure of the plating solution.

(3) Good copper sinking device

The design and application of electroless plating device play an important role in the quality of copper deposition. First of all, the tank body, hanger and heater, cooling system, circulating filter system, etc. of the electroless plating solution shall be made of inert non-metallic materials for all parts in contact with the plating solution, so as to avoid causing chemical reaction at these parts, resulting in unnecessary consumption and spontaneous decomposition failure of the plating solution.

(4) Strict process maintenance and management

When using electroless plating solution, first of all, it is necessary to keep the bath clean and stable to prevent the interference of foreign impurities and the influence of self catalytic reduction products. After each use, the solution temperature should be immediately reduced to room temperature or below the reflected temperature and filtered.

(5) Strict post-processing

As the "thin copper" process is adopted, the deposited coating is very thin and easy to be oxidized. Therefore, plating thickening treatment or oxidation resistant immersion treatment should be carried out immediately after plating to avoid oxidation and micro erosion of the coating.

(6) Prevent impurities

Strictly prevent impurities from being brought into the plating solution and treatment solution during the electroless plating process to prevent the inside from being blocked by foreign matters, which will directly affect the effect of electroless copper plating. For example, other treatment solutions are brought into the plating solution or the treated solution during substrate treatment; Washing water is brought into the treatment solution; Or the substrate falls into the plating solution or the treated solution and cannot be treated in time.

(7) Timely adjust the chemical plating solution and various treatment solutions

Strictly control the accumulation of impurities in the plating solution and various treatment solutions, and timely analyze, adjust, supplement and treat them to ensure that the composition of various solutions is within the normal range, which is the basis for improving the coating quality and preventing "black holes". PCB manufacturers, PCB designers and PCBA manufacturers will explain the overview of PCB chemical copper deposition (using formaldehyde as reducing agent).