Circuit board factory explains FPC circuit board sheet processing

Circuit board manufacturer, circuit board design and PCBA processing manufacturer explain to you: circuit board manufacturer explains FPC circuit board sheet processing

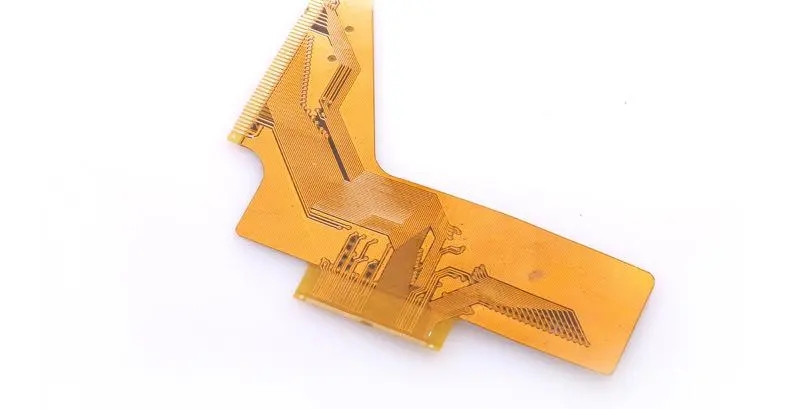

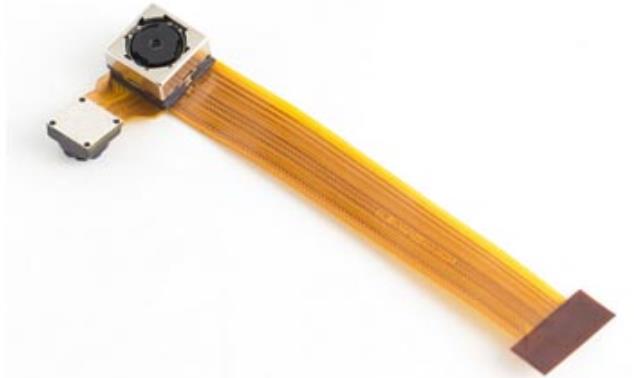

When the soft plate is attached to the cutting stiffening plate in the form of small pieces, the effect of mass production can be significantly improved. This procedure is called sheet processing. The reinforced soft boards can be operated in a way similar to a PCB, and can be sent into automatic plug-ins and combined devices for testing in a chip like manner, and then separated into individual circuit products. The procedure of sheet processing is as follows:

1. Prepare a stiffening plate containing multiple partially formed (or fully formed and then restored to sheet shape)

2. The reinforcement area is coated with adhesive

3. A piece of matching and partially formed soft plate is attached to the reinforcing plate

The auxiliary datum for the geotechnical automation plug-in, adhesion, testing and other operations in the area around the stiffening plate. The reinforced FPC can be regarded as a soft and hard bonding plate, that is, it has a state of strong in some areas and soft in some areas, and is bonded by a common extended conductor.

The soft plate reinforcement area may have PTH, in which case both the reinforcement plate and the soft plate may need to be drilled for PTH assembly. The edge of the stiffening plate should be kept smooth or smoothed to protect the soft plate from wear and pressure concentration.

Avoid sharp edges and marking

Keep a good habit, first confirm the switch connector pin and any ambiguous position that may lead to incorrect assembly. If space cannot be found on the line negative, the separated text negative shall be made by screen printing. The production must follow the specified position, ink type and color of the drawing. External printing is not expected, because it will increase the possibility of manpower and errors, but it may be unavoidable for symbols that need to be changed, such as date.

Added patch and test piece

Sometimes, FPC must consider adding terminals so that the circuit test or change can be carried out smoothly. Adding test points to standard grid points can be used to assist special circuit layout for electrical test. If it is expected to change the pattern of the electrical interconnection circuit, additional endpoints or jumpers may be designed into the circuit. If components need to be reworked/replaced from time to time, it can be expected that the gasket will eventually be damaged. At this time, the second group of terminals can be provided for future replacement.

Coupon is a valuable tool for production control, quality document establishment, engineering development and basic data collection. Various standard designs can be obtained from IPC, US military regulations and specifications from other sources. These should be linked to the production mix to gain the advantage of use, otherwise it will only waste the board area. Examples of test piece types are as follows:

1: Flexible endurance test piece

2: PTH integration section analysis test piece:

a. Post etch

b. Material thickness: electroplating, film, dielectric

3: Protective film/coating adhesion test piece

4: Dielectric property test piece:

a. Insulation

b. Dielectric strength

c. Dielectric coefficient

5: Weldability test piece

6: Thermal pressure test piece:

a. Tinning

b. Hot oil

PCB manufacturers, PCB designers and PCBA manufacturers will explain to you: PCB manufacturers will explain FPC PCB sheet processing.