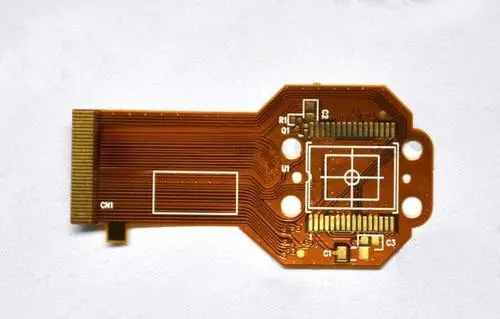

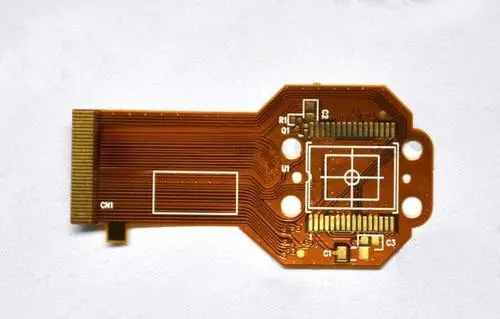

Introduction to final metal surface treatment of FPC circuit board

The circuit board manufacturer, circuit board designer and PCBA processor will explain the final metal surface treatment of FPC circuit board

Copper is a kind of active metal, which must be treated with specific materials at the exposed end to maintain weldability or allow pressure bonding after storage. Generally, optional treatment is provided by FPC manufacturer.

Gold is used for connector processing at the edge of the circuit board, and occasionally appears in highly trusted FPC designs. This treatment is generally based on electroplating technology. A layer of bottom layer is often treated at the bottom. This state means that the conductor circuit still retains the interconnection mechanism for conducting.

It is a good choice to conduct electroplating after the protective film is attached (or coated), because this means that the opening of the protective film and the electroplating treatment can ensure the integrity of alignment. There should be no exposed conductor surface and no adhesive on the electroplating surface. To carry out the electroplating after the protective film is attached, the conductor must be retained in the design, whether the outer part extending to the cutting position is cut off during forming, or can also be treated by post etching, stamping and machining removal of finished products, etc. The electroless tin plating can be used for electroplating in the exposed terminal area when the terminal does not retain the conductor.

Solder coating or tin treatment on the surface can provide excellent overall protection for soft board terminals. It can be used with subsequent (welding) assembly technology, and also in the production of many pressure connectors. Solder is a common choice for PCB surface treatment, and can be simply used in soft board applications. Unless tin penetration occurs due to poor treatment, it will lead to re melting during assembly and welding, which will certainly damage the bonding and opening of the protective film or coating.

Therefore, soldering must be carried out in the process of attaching protective film. If soldering is to be made by electroplating, it is necessary to keep the conductor. Hot air leveling soldering tin is one of the solutions. It is widely used in the production of low-cost and limited soldering tin treatment. However, high temperature and forced hot air treatment are necessary procedures, so pre baking is used to remove moisture, and then exposed to the soldering furnace for hot air leveling to remove excess soldering tin. However, this soft board processing will make the soft board slightly smaller and twisted after processing. And there is a risk of delamination. However, after the lead-free process has been promoted, the problem of high operating temperature of lead-free solder will make this process more difficult to use.

The coating of organic weld protection film is rapidly popularized because it is easy to import it into FPC plants, and the product does not need wires, and it can provide appropriate storage stability. It can be obtained from various major electrochemical suppliers, but the time required for treatment varies, mainly depending on the expected storage life and tank temperature. The practice of soaking for 1-5 minutes at room temperature to 50 ℃ is often used.

Electroless tin precipitation plating is another available option, suitable for all types of FPC, which is easy to control and has no damage to the circuit. It is a reasonable method to maintain weldability in the short term when the gasket is assumed to be clean and not over stored during the manufacturing process. The circuit board manufacturer, circuit board designer and PCBA processor will introduce the final metal surface treatment of FPC circuit board.