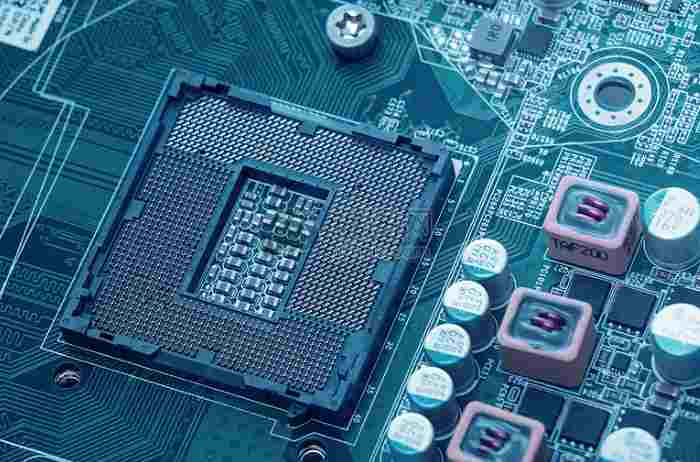

New energy vehicles are mainly divided into pure electric vehicles, hybrid electric vehicles, fuel cell vehicles, hydrogen engine vehicles and other new energy vehicles. New energy vehicles have huge potential for PCB circuit boards. With the gradual transition of traditional vehicles to autonomous driving through ADAS and the promotion of new energy vehicles, automotive electronic penetration has been increasing. With the acceleration of new energy vehicles replacing fuel vehicles, PCB circuit board applications are expected to continue to improve.

At present, the amount of PCB circuit board on a car is more than 100 pieces, LCD screen, touch screen, GPS positioning system, camera and so on all need to use PCB circuit board. The intelligent vehicle market will drive the demand for PCB circuit boards in ADAS, as a variety of operational control, safety control and peripheral control functions need to be realized through PCB circuit boards. As the trend of automobile electronization becomes clear, the trillion-level market boosts the stable growth of automobile PCB circuit boards. It is estimated that the scale of China's automobile electronic market may reach 120 billion dollars in 2020, and China will become the main market of automobile electronization.

Because the complex working environment of automobiles has a high requirement on the reliability of PCB circuit boards, automotive PCB circuit boards need to go through multi-layer testing, the threshold is relatively high, and the time is relatively long. Generally, manufacturers will not change the certified suppliers. Gaotop Electronics is a professional PCB proofing and batch processing manufacturer for domestic and foreign high-tech enterprises and scientific research institutions, committed to 2-16 layers of precision PCB circuit boards and soft and hard combined board R & D manufacturing.

What are the requirements of PCB circuit boards for new energy vehicles

In the near future, the functions and environmental requirements of automotive electronics will change dramatically. Driven by three major trends: self-driving, connected cars and the growing number of electric vehicles. PCB circuit boards are the key components of these electronic systems. Considering the requirements of automobile safety, PCB circuit boards are not only the connecting parts between the devices. Special attention must be paid to the PCB failure mode in various situations, but also put forward higher requirements on the performance of PCB circuit boards.

Unmanned front Lidar circuit board

In a driverless car powered by a few hundred volts, the PCB circuit boards must be kept running reliably. PCBS in cars are affected by the environment during their life, such as temperature, humidity and vibration load. Considering the electrical characteristics of PCB substrates, automotive applications must take into account production tolerances and environmental impacts, such as temperature and humidity, which can affect electrical values. For example, both the relative permittivity and the dielectric loss of the material decrease during thermal aging, but the permittivity increases as the moisture content in the epoxy resin material increases.

The functional requirements of new energy vehicles are also varied. The use of PCB circuit boards in electric vehicles may be a cost-effective solution, but the PCB circuit boards must be able to withstand several hundred amperes of current over a million hour lifetime and voltages up to 1000 volts in the automotive environment. On the one hand, the closer to the actuator, such as the power electronics to withstand higher temperatures. On the other hand, electronic devices such as on-board computers are better protected against external stresses and require a longer service life due to charging times and 24-hour service.

Impedance-controlled PCB lamination and PCB process control are standard in the consumer industry, and the automotive industry must ensure high-quality signal integrity and power integrity, and have good electromagnetic compatibility. The application of PCB circuit boards in new energy vehicles can be further understood by clicking on the application analysis of PCB circuit boards in the automotive electronics industry. Special attention needs to be paid to the selection of materials to ensure stability in terms of temperature, humidity and bias in addition to electrical properties. This will lead to future restrictions on material selection and design rules. In order to ensure the necessary electrical properties, PCB manufacturers should be certified for high speed applications.