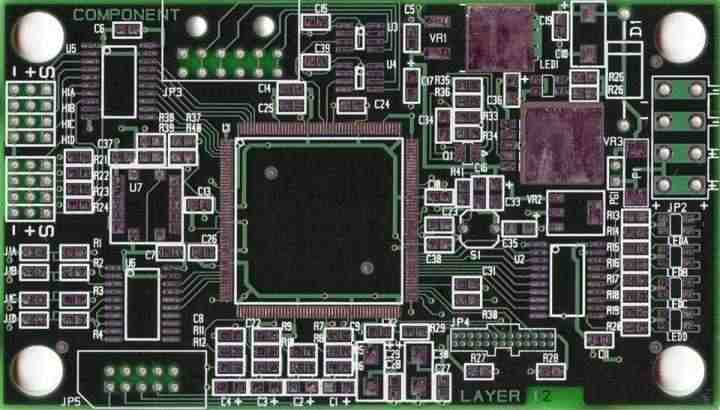

Circuit board repair is a new repair industry. The degree of automation of industrial equipment is getting higher and higher, so the number of industrial control board in various industries is also increasing. After the industrial control board is damaged, the high cost required to replace the circuit board (at least thousands of yuan, more than tens of thousands or hundreds of thousands of yuan) has become a very headache for the enterprises. In fact, the vast majority of these damaged circuit boards can be repaired in China, and the cost is only 20%-30% of the purchase of a new board, the time used is much shorter than the foreign fixed board. The following introduces the basic knowledge of circuit board maintenance.

Almost all circuit board maintenance without drawing materials, so many people are skeptical about circuit board maintenance, although various circuit boards vary, but the same is that each circuit board is composed of a variety of integrated blocks, resistors, capacitors and other devices, so the circuit board damage must be caused by one or some of the device damage, The idea of circuit board maintenance is established based on the above factors. Circuit board maintenance is divided into two parts: inspection and maintenance, among which inspection occupies a very important position. The basic knowledge of each device on the circuit board is repaired and tested until the bad parts are found and replaced, so a circuit board is repaired.

Circuit board detection is the process of finding, determining and correcting the fault of each electronic component on the circuit board. In fact, the whole detection process is the thinking process and the testing process of providing logical reasoning clues, so the detection engineer must gradually accumulate experience in the maintenance, testing and overhaul of the circuit board, and constantly improve the level. General electronic equipment is composed of tens of thousands of components, in the maintenance, overhaul, if by direct test and check each component in the circuit board to find the problem will be very time-consuming, implementation is also very difficult. So from the fault phenomenon to the fault cause of the type of check, is an important maintenance method. As long as the circuit board has detected the problem, then maintenance is easy. The above is the basic knowledge of circuit board maintenance.

Cost standard:

Charge standard

The charge of maintenance costs does not exceed 30% of the original value of the electronic board, followed by according to the degree of circuit board broken, the degree of difficulty, the number of parts, the cost of four aspects of charge, special cases, as appropriate.

Maintenance instructions

Inspection of Industrial Control products is free.

After the customer confirms the repair, we will bear the transportation cost.

The maintenance party should give reasonable charges according to the fault situation after detection.

Products repaired by the guest service should be given a three-month warranty.

Acceptance

After the base plate is handed over to the user, the user must inform the contractor within one week. If the base plate is not passed, it shall be returned to the contractor for repair. Otherwise, it is deemed that it has not passed. If the machine (plate) cannot be tested under special circumstances, the customer must inform the contractor in advance.

Reform and copy

In case of improving, customizing or replacing the imported substrate for the ready-made substrate of the customer, the cost shall be determined by the parties through negotiation according to the degree of ease and the quantity of substrate, and the demander shall pay 50% of the total price in advance.

Engineering quotation

⒈ Design circuit, oil circuit, gas circuit and circuit diagram free of charge according to customer requirements. According to the size of the project, the selection of materials, the selection of equipment, should be within a week to offer to customers.

Distribution of processing plants

Circuit board processing plants in the north and south are distributed, the south of the multilayer circuit board is more, the north is single-sided circuit board, mainly rigid printed board, aluminum substrate, Xiangyu circuit board.

maintenance

In use, the circuit board should be maintained regularly to ensure that the circuit board works in good condition and reduce the failure rate of the circuit board. The maintenance of the circuit board in use is divided into the following situations:

1. Semi-maintenance:

The dust on the circuit board is cleaned every quarter. The circuit board can be cleaned with special cleaning liquid. After cleaning the dust on the circuit board, the circuit board can be dried with a hair dryer.

Observe that the electronic components in the circuit have no traces of high temperature, electrolytic capacitor has no bulge leakage phenomenon, if there should be replaced.

2. Annual maintenance:

⑴ Clean the dust on the circuit board.

The capacity of electrolytic capacitor on the circuit board for spot check, such as the capacity of electrolytic capacitor is found to be less than 20% of the nominal capacity, should be replaced, the general life of the electrolytic capacitor about ten years should be replaced, in order to ensure the performance of the circuit board.

(3) For the high power devices coated with heat dissipation silicone grease, should check the heat dissipation silicone grease is not dry solid, for the dry solid should be dry solid heat dissipation silicone grease removed, coated with new heat dissipation silicone grease, in order to prevent the high power devices in the circuit board because of bad heat dissipation and burn out.

History of development:

Circuit board is the most active industry in the contemporary electronic components industry, its industry growth rate is generally higher than the electronic components industry about 3 percentage points.

Printed circuit board aluminum based circuit board

Printed circuit board is the most active industry in the contemporary electronic components industry, its industry growth rate is generally about 3 percentage points higher than the electronic components industry. It is expected to maintain rapid growth in 2006, demand upgrading and industrial transfer are the basic driving force to promote the development of the industry, and HDI board, flexible board, IC packaging board (BGA, CSP) and other varieties will become the main growth point.

In 2003, the output value of China's printed circuit boards was 500.69 billion yuan, with a year-on-year growth of 333%, and the output value exceeded the United States, which ranked second in the world for the first time. In 2004 and 2005, the output value of PCB in China still maintained a growth rate of more than 30%, estimated to reach 86.9 billion yuan in 2005, much higher than the growth rate of the global industry.

Flexible circuit board is rapidly developing in the direction of miniaturization of electronic equipment represented by smart phone, so it is widely used in many electronic equipment market segments. On the one hand, products tend to be miniaturized; Reliability on the other hand. The global value of flexible circuit boards is expected to reach $13.2 billion by 2016, with a compound annual growth rate of 7.5%, making the survey one of the fastest growing sub-sectors in the electronics industry.

From the form of development, China's circuit board industry continues to grow at a high speed, and imports and exports have also achieved a high speed of growth. With the growth of the industry, it is gradually optimized and improved.