The next stage is product implementation. At this stage, product documentation is collected and compiled, including all manuals, catalogs, and related product documentation.

No product is ever perfect, so there is always a way to make PCB products better. However, much of this evaluation will require comments and feedback from some initial users of the product. This is a form of quality assurance because a group of users needs to thoroughly use the product and provide feedback.

production

Only after all the preceding stages have been completed can the product finally enter the mass production stage and finally be released into the market. When users start buying a product, it's important to allow them to submit their own feedback and then use it to improve the product over and over again to make it more optimized.

Important considerations for NPI

Although the NPI process has been developed, there are other important considerations when manufacturing PCBS.

location

Manufacturers are all over the world. Many of these offer competitive prices for their products, which may tempt many producers to save money by using these services. However, hiring these manufacturers brings difficulties and risks. Time zone differences and language barriers can stifle effective communication. If the production process needs to change, it is difficult to make these arrangements and ensure their application.

By hiring local manufacturers, producers can ensure real-time communication, access, and application of any changes to keep the manufacturing process running smoothly. In addition, it is easier to verify the qualifications, certification, competence and reputation of local manufacturers.

Manufacturing flexibility

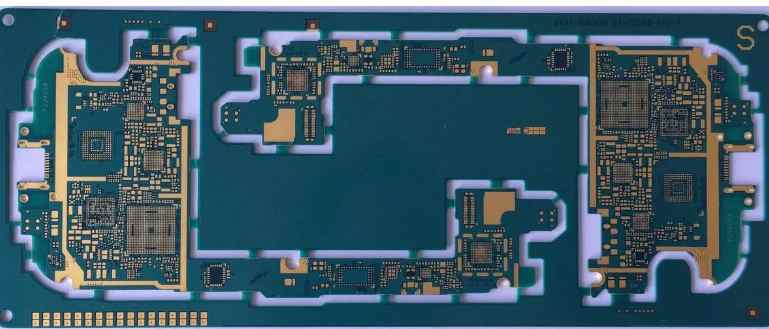

PCB manufacturers will be involved in mass production of products, which means production will need to be streamlined. This can be problematic if the production process requires structural or architectural changes during this process. Many manufacturers simply do not have the flexibility to make sudden changes to their processes. However, those who specialize in highly mixed builds are more likely to have methods in place that allow them to adapt to the changes required in a production environment. This includes manually monitoring changes in the process, build changes, and adaptation of new prototypes.

Professional knowledge

The NPI process focuses on preparing the design for production build, making it important for the manufacturer to have a high level of engineering expertise. When changes need to be made, be it PCB schematics or board layouts, and experienced staff who should be able to verify the feasibility and manufacturability of these production changes. They should also know how to adequately update documentation for changed products.

Access component

Manufacturing with high quality components is essential to ensure a good product and a good reputation in the market. When prototyping, it is often older parts that may not be readily available for bulk purchase (or are completely unavailable), so the contract manufacturer must be able to obtain quality and adequate replacement parts without compromising the quality of the product. When components are hard to come by, manufacturers must have access to distribution networks and other manufacturers who can supply the necessary components and materials.

Sometimes, a reduction in the number of specific component types on the market will force a manufacturer to adopt a new component. In mass production, conversion needs to be able to accommodate long-term production, plan and logistics around any procurement changes, and ensure a steady flow of access to replacement products.

Stable business relationship

CM needs to establish good business relationships with various parts suppliers, circuit board manufacturers on which PCBS are based, and various engineering services and quality testing services.

Conclusion of new product introduction

There are many challenges to launching a new product, from practical to logistical, and there is never a "perfect" scenario. To optimize production, the NPI process from conceptualization to mass production allows for a phased approach to streamline quality products, with safeguards in place to ensure high quality component procurement, flexibility, expertise, and high-end end output.

Tao fang's team of experts has successfully helped hundreds of Oems and engineers acquire their designs through prototyping, NPI and full production. If you have an idea or design, we are happy to help you turn your dream into a reality. Browse our website for our products.